Table of Contents

Tips for Maintaining and Optimizing Performance of Staple Wire Drawing Machine For Copper Wire Manufacturing

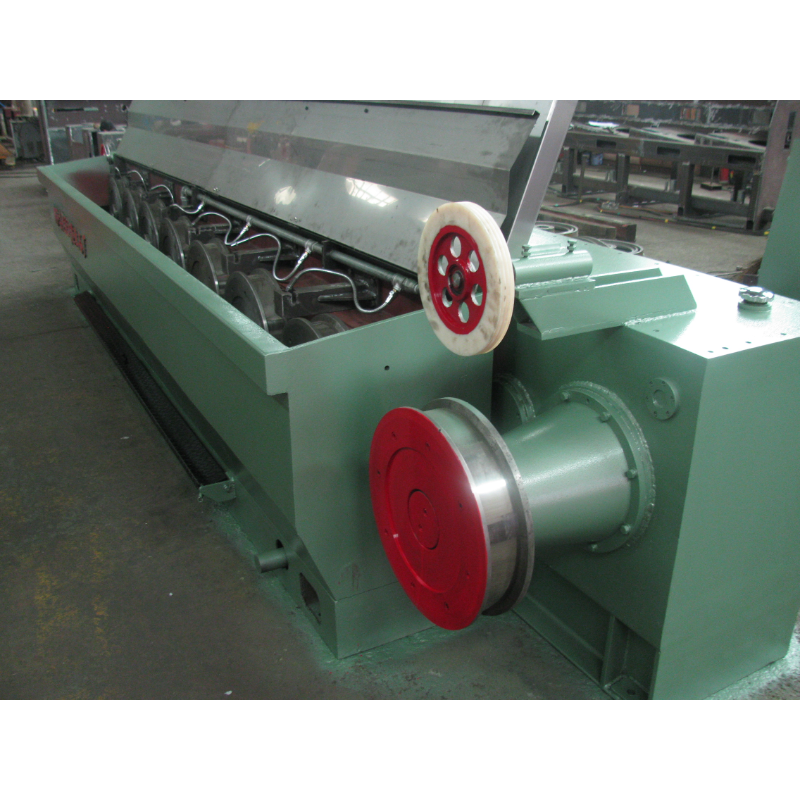

Staple wire drawing machines are essential equipment in the manufacturing process of copper wire. These machines are used to reduce the diameter of copper wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. To ensure the optimal performance of staple wire drawing machines, it is important to follow proper maintenance procedures and implement strategies to optimize their efficiency.

One of the key factors in maintaining staple wire drawing machines is regular cleaning and lubrication. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased performance and potential damage to the machine. By regularly cleaning and lubricating the machine, you can prevent these issues and prolong its lifespan.

In addition to cleaning and lubrication, it is important to regularly inspect the machine for any signs of wear or damage. Check for loose or worn parts, such as belts, pulleys, and bearings, and replace them as needed. By addressing these issues promptly, you can prevent more serious problems from occurring and ensure the machine continues to operate smoothly.

Another important aspect of maintaining staple wire drawing machines is monitoring their performance and making adjustments as needed. Keep an eye on the wire tension, speed, and temperature to ensure they are within the recommended parameters. If you notice any fluctuations or irregularities, make the necessary adjustments to optimize the machine’s performance.

To further optimize the performance of Copper Fine Wire Drawing Machine With Annealer, consider implementing preventive maintenance measures. This can include scheduling regular maintenance checks, replacing worn parts before they fail, and keeping detailed records of maintenance activities. By taking a proactive approach to maintenance, you can prevent costly downtime and ensure the machine operates at its best.

In addition to maintenance, there are several strategies you can implement to optimize the performance of staple wire drawing machines. One such strategy is to use high-quality dies and lubricants. By investing in premium dies and lubricants, you can improve the quality of the drawn wire and reduce the risk of machine breakdowns.

Another strategy is to optimize the machine’s speed and tension settings. By adjusting these parameters to the optimal levels, you can increase the efficiency of the drawing process and produce higher-quality wire. Experiment with different settings to find the ideal combination for your specific manufacturing needs.

Furthermore, consider investing in training for machine operators to ensure they are familiar with the proper operation and maintenance procedures. By providing comprehensive training, you can empower operators to identify and address issues before they escalate, leading to improved machine performance and productivity.

In conclusion, staple wire drawing machines play a crucial role in the manufacturing of copper wire. By following proper maintenance procedures, monitoring performance, and implementing optimization strategies, you can ensure these machines operate at their best. With regular maintenance and proactive measures, you can prolong the lifespan of staple wire drawing machines and achieve optimal performance in copper wire manufacturing.

Benefits of Using a Staple Wire Drawing Machine for Copper Wire Production

Copper wire is a versatile material that is used in a wide range of industries, from electronics to construction. In order to produce high-quality copper wire, manufacturers rely on staple wire drawing machines. These machines play a crucial role in the production process, helping to transform raw copper into the fine wire that is used in various applications.

One of the key benefits of using a staple wire drawing machine for Copper Wire Drawing Machine is the ability to control the diameter of the wire. By passing the copper through a series of dies with progressively smaller openings, the machine can reduce the diameter of the wire to the desired size. This level of precision is essential for ensuring that the wire meets the specifications required for its intended use.

In addition to controlling the diameter of the wire, staple wire drawing machines also help to improve the surface finish of the wire. As the copper is drawn through the dies, any imperfections or irregularities on the surface of the wire are smoothed out, resulting in a clean and uniform finish. This is important for ensuring that the wire is free from defects that could affect its performance in the final product.

Another benefit of using a staple wire drawing machine for copper wire production is the ability to increase the strength of the wire. By subjecting the copper to the drawing process, the grain structure of the metal is refined, resulting in a stronger and more durable wire. This is particularly important for applications where the wire will be subjected to high levels of stress or tension.

Furthermore, staple wire drawing machines are highly efficient, allowing manufacturers to produce large quantities of copper wire in a relatively short amount of time. This is essential for meeting the demands of the market and ensuring that products are delivered on time. Additionally, the machines are designed to operate continuously, with minimal downtime, further increasing productivity and reducing costs.

In conclusion, staple wire drawing machines play a crucial role in the production of high-quality copper wire. By controlling the diameter of the wire, improving the surface finish, and increasing the strength of the wire, these machines help to ensure that the wire meets the specifications required for its intended use. Furthermore, their efficiency and reliability make them an essential tool for manufacturers looking to produce copper wire in large quantities. Overall, staple wire drawing machines offer a range of benefits that make them an indispensable part of the copper wire production process.