Table of Contents

Maintenance Tips for Keeping Copper Wire Drawing Machine Running Smoothly

Copper wire drawing machines are essential equipment in the manufacturing industry, used to produce high-quality copper wires of various sizes and shapes. These machines are complex and require regular maintenance to ensure they run smoothly and efficiently. Proper maintenance not only extends the lifespan of the machines but also helps to prevent costly breakdowns and production delays.

One of the most important maintenance tasks for copper wire drawing machines is keeping them clean. Dust, dirt, and debris can accumulate on the machine’s components, causing friction and wear. Regular cleaning with a soft brush or cloth can help prevent this buildup and keep the machine running smoothly. It is also important to lubricate the moving parts of the machine regularly to reduce friction and prevent premature wear.

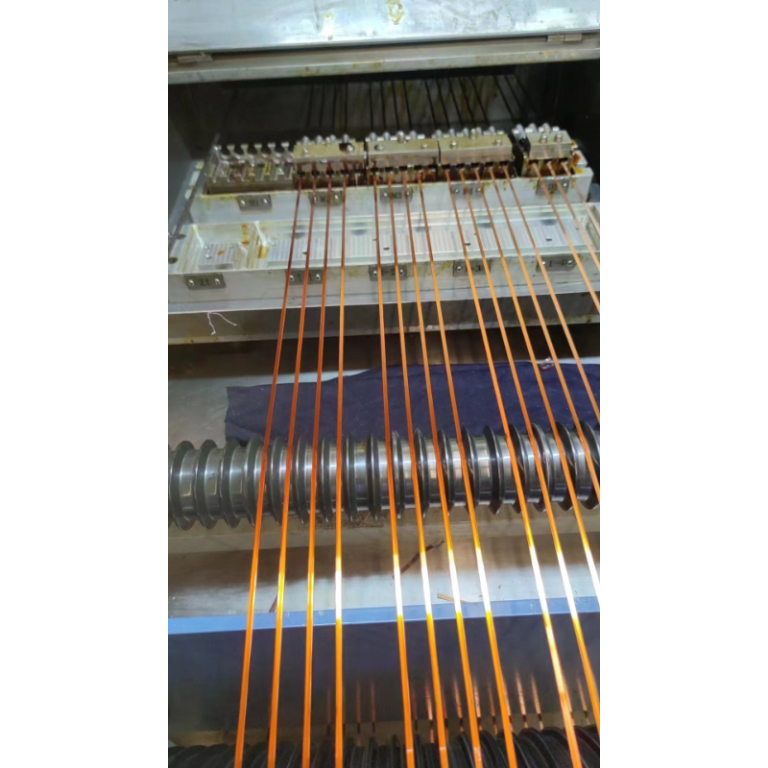

In addition to cleaning and lubricating, it is crucial to inspect the machine’s components regularly for signs of wear or damage. Check the wire drawing dies, rollers, and bearings for any signs of wear, such as cracks or dents. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure consistent wire quality.

Another important maintenance task for Wet Type Drawing Machines For Copper Wire is monitoring the tension of the wire during the drawing process. Proper tension is crucial for producing high-quality wire, and improper tension can lead to wire breakage or uneven wire diameter. Regularly check the tension settings on the machine and make adjustments as needed to ensure consistent wire quality.

It is also important to monitor the temperature of the machine during operation. Overheating can cause damage to the machine’s components and affect the quality of the wire produced. Make sure the machine is properly ventilated and that cooling systems are functioning correctly. If the machine overheats, stop production immediately and allow it to cool down before resuming operation.

Regularly inspecting and maintaining the electrical components of the machine is also crucial for its efficient operation. Check the wiring, connections, and electrical controls for any signs of wear or damage. Replace any damaged components immediately to prevent electrical malfunctions and ensure the safety of the machine operators.

In conclusion, proper maintenance is essential for keeping copper wire drawing machines running smoothly and efficiently. Regular cleaning, lubrication, inspection, and monitoring of the machine’s components are crucial tasks that should be performed regularly to prevent breakdowns and ensure consistent wire quality. By following these maintenance tips, you can extend the lifespan of your copper wire drawing machines and maximize their productivity.

Benefits of Using Efficient Copper Wire Drawing Machines

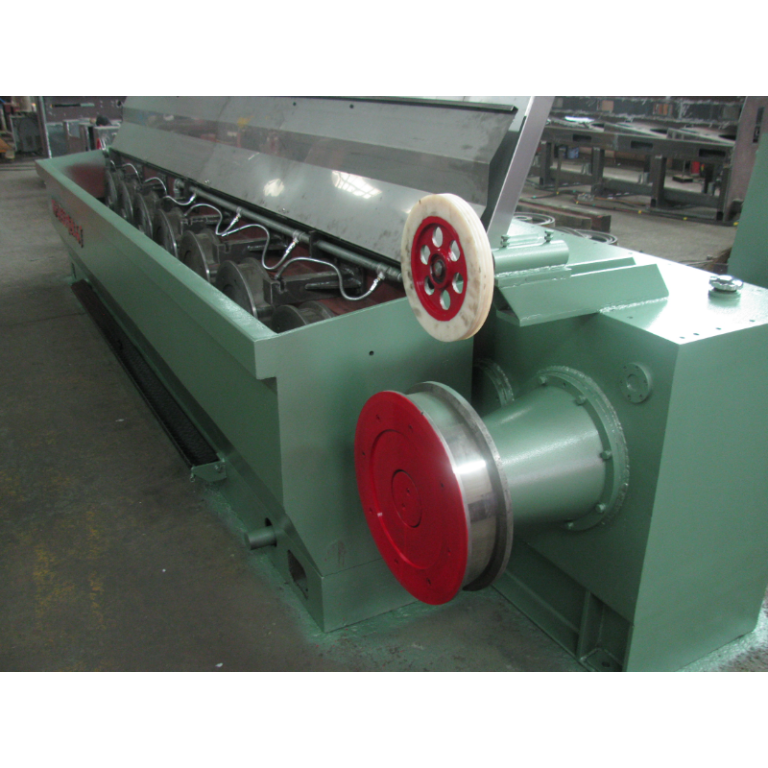

Copper wire drawing machines are essential tools in the manufacturing industry for producing high-quality copper wires. These machines are designed to efficiently draw copper rods through a series of dies to reduce their diameter and improve their quality. Using efficient copper wire drawing machines offers a wide range of benefits for manufacturers, including increased productivity, cost savings, and improved product quality.

One of the primary benefits of using efficient copper wire drawing machines is increased productivity. These machines are capable of drawing copper wires at high speeds, allowing manufacturers to produce a large volume of wires in a short amount of time. This increased productivity can help manufacturers meet tight production deadlines and fulfill customer orders quickly and efficiently.

In addition to increased productivity, efficient copper wire drawing machines can also help manufacturers save money. By drawing copper wires with precision and accuracy, these machines can minimize material waste and reduce production costs. This cost savings can be significant for manufacturers, especially those operating on tight budgets or facing increasing competition in the market.

Furthermore, efficient Copper Rod Casting and Making Machine can also improve the quality of the copper wires produced. These machines are designed to draw wires with consistent diameter and smooth surfaces, resulting in high-quality wires that meet industry standards. This improved product quality can enhance the reputation of manufacturers and help them attract more customers who value reliability and consistency in their products.

Another benefit of using efficient copper wire drawing machines is their versatility. These machines can be used to draw copper wires of various diameters and lengths, making them suitable for a wide range of applications in different industries. Whether manufacturers need thin wires for electronics or thick wires for construction, efficient copper wire drawing machines can meet their specific requirements with ease.

Moreover, efficient copper wire drawing machines are also easy to operate and maintain. These machines are equipped with user-friendly controls and features that make them simple to use, even for operators with minimal training or experience. Additionally, these machines are built to last and require minimal maintenance, reducing downtime and ensuring continuous production for manufacturers.

In conclusion, efficient copper wire drawing machines offer a wide range of benefits for manufacturers in the manufacturing industry. From increased productivity and cost savings to improved product quality and versatility, these machines can help manufacturers meet their production goals and deliver high-quality copper wires to their customers. With their ease of operation and maintenance, efficient copper wire drawing machines are essential tools for any manufacturer looking to enhance their production processes and stay competitive in the market.

How to Choose the Right Copper Wire Drawing Machine for Your Needs

Copper wire drawing machines are essential tools in the manufacturing industry, used to produce high-quality copper wires of various sizes and shapes. These machines are designed to efficiently pull copper rods through a series of dies to reduce their diameter and improve their quality. Choosing the right copper wire drawing machine for your specific needs is crucial to ensure optimal performance and productivity.

When selecting a Copper Fine Wire Drawing Machine With Annealer, there are several factors to consider. The first consideration is the size and type of copper fine wire you need to produce. Different machines are designed to handle different wire sizes and shapes, so it is important to choose a machine that can accommodate your specific requirements. Additionally, consider the production capacity of the machine, as well as its speed and efficiency.

Another important factor to consider when choosing a copper wire drawing machine is the quality of the materials used in its construction. High-quality materials will ensure the durability and longevity of the machine, as well as the quality of the copper wire it produces. Look for machines made from high-grade steel or other durable materials that can withstand the rigors of continuous use.

It is also important to consider the reputation of the manufacturer when choosing a copper wire drawing machine. Look for manufacturers with a proven track record of producing high-quality machines that meet industry standards. Reading reviews and testimonials from other customers can help you gauge the reliability and performance of a particular manufacturer.

In addition to the machine itself, consider the level of customer support and service offered by the manufacturer. A reputable manufacturer will provide excellent customer service, including technical support, training, and maintenance services. This can be crucial in ensuring the smooth operation of your copper wire drawing machine and minimizing downtime.

When choosing a copper wire drawing machine, it is also important to consider your budget. Prices for these machines can vary widely depending on their size, capacity, and features. It is important to balance cost with quality and performance to ensure that you get the best value for your investment.

In conclusion, choosing the right copper wire drawing machine for your needs requires careful consideration of several factors, including the size and type of wire you need to produce, the quality of materials used in the machine’s construction, the reputation of the manufacturer, customer support and service, and your budget. By taking the time to research and evaluate your options, you can select a machine that meets your specific requirements and helps you achieve optimal performance and productivity in your manufacturing operations.