Table of Contents

Maintenance Tips for Rod Breakdown Machine to Ensure Optimal Performance

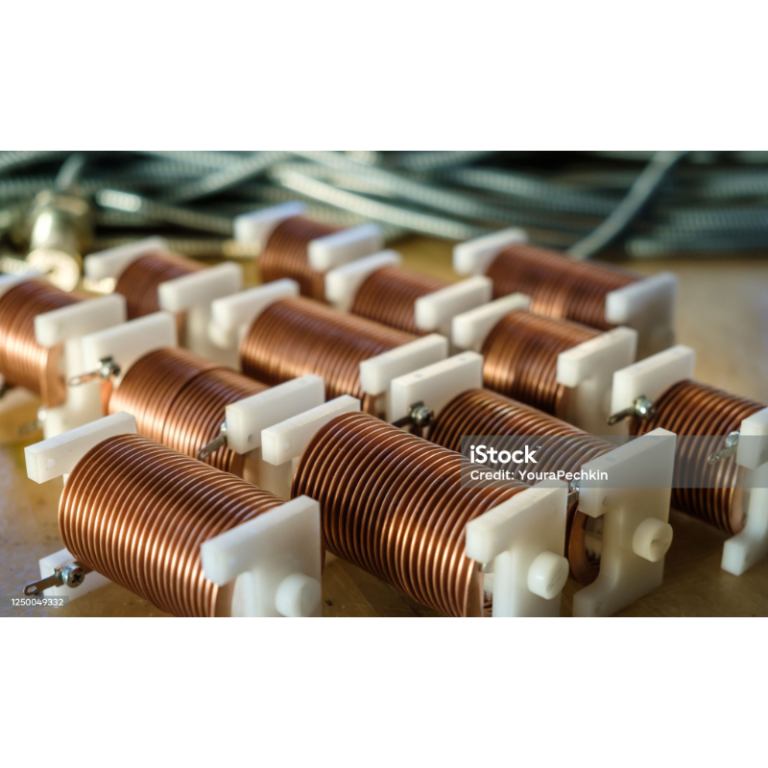

A rod breakdown machine is a crucial piece of equipment in the wire drawing process, especially when it comes to producing copper wire. This machine is responsible for reducing the diameter of copper rods to the desired size, making them suitable for further processing. To ensure that the rod breakdown machine operates efficiently and effectively, regular maintenance is essential. In this article, we will discuss some maintenance tips that can help you keep your rod breakdown machine in optimal condition.

One of the most important maintenance tasks for a Copper Fine Wire Drawing Machine With Annealer is regular cleaning. Over time, dust, dirt, and other debris can accumulate on the machine’s components, leading to decreased performance and potential breakdowns. To prevent this from happening, it is important to clean the machine regularly using a soft brush or cloth. Pay special attention to areas where debris tends to build up, such as the wire guides and rollers.

In addition to cleaning, lubrication is another key aspect of rod breakdown machine maintenance. Proper lubrication helps reduce friction between moving parts, prolonging the machine’s lifespan and ensuring smooth operation. Be sure to use the recommended lubricants for each component of the machine and follow the manufacturer’s guidelines for lubrication frequency.

Regular inspection of the machine’s components is also crucial for maintaining optimal performance. Check for any signs of wear or damage, such as worn-out wire guides or misaligned rollers. Replace any damaged parts immediately to prevent further issues and ensure the machine continues to function properly.

Another important maintenance tip for rod breakdown machines is to monitor the machine’s operating temperature. Excessive heat can cause components to expand and contract, leading to misalignment and potential damage. Keep an eye on the machine’s temperature gauge and make adjustments as needed to maintain a stable operating temperature.

It is also important to regularly check the tension of the wire being fed into the machine. Improper tension can lead to wire breakage or other issues that can affect the machine’s performance. Make sure the wire is properly aligned and tensioned before starting the machine to prevent any problems.

Lastly, scheduling regular maintenance checks with a qualified technician can help identify any potential issues before they escalate into major problems. A professional inspection can help ensure that all components are in good working order and that the machine is operating at peak efficiency.

In conclusion, proper maintenance is essential for ensuring the optimal performance of a rod breakdown machine used for producing copper wire. By following these maintenance tips, you can help prolong the lifespan of your machine, prevent breakdowns, and ensure that your wire drawing process runs smoothly. Remember to clean the machine regularly, lubricate moving parts, inspect components for wear and damage, monitor operating temperature, check wire tension, and schedule regular maintenance checks with a qualified technician. By taking these steps, you can keep your rod breakdown machine in top condition and maximize its efficiency and productivity.

Advantages of Using Rod Breakdown Machine for Copper Wire Production

Copper wire is a crucial component in various industries, including telecommunications, electronics, and power distribution. The quality of copper wire plays a significant role in the performance and reliability of the end products. To ensure high-quality copper wire production, manufacturers rely on advanced machinery such as the rod breakdown machine.

The rod breakdown machine is a specialized piece of equipment designed to reduce the diameter of copper rods to the desired size for wire drawing. This process involves passing the copper rod through a series of dies to gradually decrease its diameter. The machine is equipped with multiple drawing dies that are carefully calibrated to ensure precise reduction in diameter without compromising the integrity of the copper wire.

One of the key advantages of using a rod breakdown machine for Copper Wire Drawing Machine is its ability to produce wire with consistent diameter and quality. The machine is designed to control the drawing process with precision, resulting in uniform wire that meets the required specifications. This consistency is essential for applications where the performance and reliability of the copper wire are critical.

In addition to producing high-quality wire, the rod breakdown machine also offers increased efficiency in the production process. By automating the drawing process, the machine can handle large volumes of copper rods with minimal manual intervention. This not only speeds up the production process but also reduces the risk of errors and inconsistencies that can occur with manual drawing methods.

Furthermore, the rod breakdown machine is designed to operate at high speeds, allowing manufacturers to meet tight production deadlines and customer demands. The machine can process copper rods quickly and efficiently, ensuring a steady supply of high-quality wire for various applications. This speed and efficiency make the rod breakdown machine an essential tool for manufacturers looking to increase their production capacity and meet market demands.

Another advantage of using a rod breakdown machine is its versatility in handling different types of copper rods. The machine can accommodate various sizes and types of copper rods, allowing manufacturers to produce a wide range of wire diameters to meet specific requirements. This flexibility makes the rod breakdown machine a valuable asset for manufacturers working on diverse projects with varying specifications.

Moreover, the rod breakdown machine is designed for durability and reliability, ensuring long-term performance and minimal downtime. The machine is built with high-quality materials and components that can withstand the rigors of continuous operation. This reliability is crucial for manufacturers looking to maintain consistent production output and meet customer expectations.

In conclusion, the rod breakdown machine offers numerous advantages for copper wire production, including high-quality output, increased efficiency, versatility, and reliability. By investing in this advanced machinery, manufacturers can enhance their production processes, improve product quality, and stay competitive in the market. The rod breakdown machine is a valuable asset for any manufacturer looking to streamline their copper wire production and achieve success in the industry.