Table of Contents

The History of Enameling Machines in China

The Enameling Wire Production Line have played a crucial role in the manufacturing industry in China for centuries. The history of enameling machines in China dates back to ancient times when artisans used traditional methods to create intricate designs on metal surfaces. These early techniques laid the foundation for the development of modern enameling machines that are used in factories across the country today.

One of the earliest forms of enameling in China can be traced back to the Shang dynasty, which ruled from around 1600 to 1046 BC. During this time, artisans used a technique known as cloisonné to create colorful designs on metal objects. Cloisonné involves creating compartments, or cloisons, on a metal surface and filling them with colored enamel. The object is then fired in a kiln to fuse the enamel to the metal, creating a durable and vibrant finish.

As the centuries passed, the art of enameling continued to evolve in China. During the Ming dynasty (1368-1644), artisans developed new techniques and styles, such as painted enamel and translucent enamel. These advancements in enameling techniques paved the way for the development of mechanized enameling machines in the modern era.

The industrial revolution in the 19th century brought about significant changes in the manufacturing industry, including the development of automated machinery for mass production. Enameling Machine for Copper Wire were among the many innovations that emerged during this time, allowing manufacturers to produce enameled products more efficiently and cost-effectively.

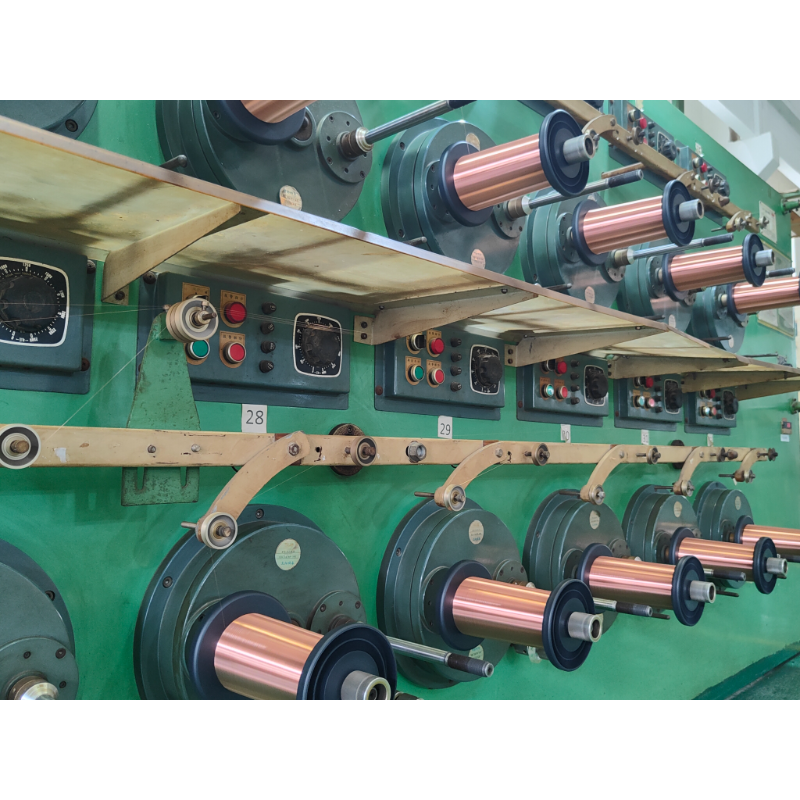

In China, the demand for enameled products grew rapidly as the country’s economy expanded. To meet this demand, Chinese manufacturers began investing in state-of-the-art enameling machines that could produce high-quality enameled products in large quantities. These machines were equipped with advanced technology, such as automated enamel application systems and precision control mechanisms, to ensure consistent and uniform finishes on a wide range of metal objects.

Today, China is one of the leading producers of enameled products in the world, thanks in large part to the advanced enameling machines that are used in factories across the country. These machines are capable of producing a wide variety of enameled products, from household items like cookware and jewelry to industrial components like electrical insulation and automotive parts.

The development of Enameling Machine for Aluminum Wire in China has not only revolutionized the manufacturing industry but has also helped to preserve the country’s rich tradition of enameling. By combining traditional craftsmanship with modern technology, Chinese manufacturers are able to create enameled products that are both aesthetically pleasing and durable.

In conclusion, the history of enameling machines in China is a testament to the country’s long-standing tradition of craftsmanship and innovation. From the early days of cloisonné to the modern era of automated enameling machines, Chinese artisans and manufacturers have continued to push the boundaries of what is possible with enamel. Today, enameling machines play a vital role in the production of enameled products in China, ensuring that this ancient art form continues to thrive in the modern world.

Advancements in Enameling Technology in Chinese Machines

Enameling machines have played a crucial role in the manufacturing industry, particularly in the production of enamel-coated products such as cookware, bathtubs, and electrical appliances. In recent years, China has emerged as a leading producer of enameling machines, with advancements in technology driving the growth of this sector.

One of the key advancements in enameling technology in Chinese machines is the development of automated systems. These systems have significantly improved the efficiency and accuracy of the enameling process, reducing the need for manual labor and increasing productivity. By automating various stages of the enameling process, Chinese machines are able to produce high-quality enamel-coated products at a faster rate, meeting the demands of the market.

Another important advancement in Chinese Vertical Enameling Machine is the integration of digital controls and monitoring systems. These systems allow operators to closely monitor and adjust various parameters such as temperature, speed, and coating thickness, ensuring consistent and uniform enamel coatings on products. By utilizing digital controls, Chinese machines are able to achieve a higher level of precision and quality in the enameling process, resulting in products that meet the highest standards of durability and aesthetics.

Furthermore, Chinese enameling machines have also made significant strides in terms of energy efficiency and environmental sustainability. By incorporating energy-saving technologies such as heat recovery systems and efficient insulation materials, Chinese machines are able to reduce energy consumption and minimize waste in the enameling process. This not only helps manufacturers reduce their operating costs but also contributes to a more sustainable and eco-friendly production process.

In addition to technological advancements, Chinese enameling machines have also benefited from improvements in materials and design. Manufacturers have developed new enamel formulations that offer enhanced durability, chemical resistance, and color options, allowing for a wider range of applications and design possibilities. Furthermore, the design of enameling machines has been optimized for ease of use, maintenance, and cleaning, making them more user-friendly and cost-effective for manufacturers.

Overall, the advancements in enameling technology in Chinese machines have revolutionized the way enamel-coated products are manufactured. By incorporating automated systems, digital controls, energy-saving technologies, and innovative materials and design, Chinese machines are able to produce high-quality enamel-coated products efficiently, sustainably, and cost-effectively. As a result, China has become a key player in the global enameling machine market, providing manufacturers with cutting-edge solutions for their enameling needs.

In conclusion, the advancements in enameling technology in Chinese machines have set a new standard for the industry, driving innovation, efficiency, and sustainability in the production of enamel-coated products. With continued research and development, Chinese manufacturers are poised to further enhance the capabilities of enameling machines, offering even more advanced solutions for the manufacturing industry. As the demand for high-quality enamel-coated products continues to grow, Chinese machines are well-positioned to meet the needs of manufacturers around the world, solidifying their reputation as leaders in enameling technology.

Top Enameling Machine Manufacturers in China

Enameling machines play a crucial role in the manufacturing process of various products, including cookware, electrical appliances, and automotive parts. These machines are designed to apply a protective and decorative enamel coating to metal surfaces, enhancing their durability and aesthetic appeal. In China, a country known for its manufacturing prowess, there are several top enameling machine manufacturers that are leading the industry with their innovative technologies and high-quality products.

One of the top enameling machine manufacturers in China is Guangdong Han’s Yueming Laser Group Co., Ltd. With over 20 years of experience in the industry, this company has established itself as a trusted provider of advanced enameling solutions. Their Wire Enameling Plant are known for their precision, efficiency, and reliability, making them a popular choice among manufacturers looking to enhance their production processes.

Another leading manufacturer in China is Shenzhen Superb Heater Technology Co., Ltd. This company specializes in the production of enameling machines for a wide range of applications, including cookware, automotive parts, and industrial components. Their machines are designed to deliver consistent and high-quality enamel coatings, ensuring that the finished products meet the highest standards of quality and durability.

Shanghai Fortune Electric Co., Ltd. is also a prominent player in the enameling machine industry in China. With a focus on innovation and technological advancement, this company has developed a range of cutting-edge enameling machines that offer superior performance and efficiency. Their machines are equipped with advanced features such as automatic temperature control, precise coating thickness adjustment, and energy-saving capabilities, making them ideal for manufacturers looking to optimize their production processes.

In addition to these top manufacturers, there are several other companies in China that are making a mark in the enameling machine industry. Jiangsu Huaxin Machinery Co., Ltd. is known for its high-quality enameling machines that are designed to meet the specific needs of different industries. From small-scale production to large-scale manufacturing, their machines are versatile and reliable, making them a popular choice among a wide range of customers.

Zhejiang Zhenbo Precision Machinery Co., Ltd. is another key player in the Chinese enameling machine market. This company specializes in the production of enameling machines for the electrical and electronics industry, offering customized solutions to meet the unique requirements of their customers. With a focus on quality and innovation, they have earned a reputation for delivering top-notch products that exceed customer expectations.

Overall, the enameling machine industry in China is thriving, with several top manufacturers leading the way with their innovative technologies and high-quality products. Whether you are in the market for a new enameling machine or looking to upgrade your existing equipment, these manufacturers offer a wide range of solutions to meet your specific needs. With their commitment to excellence and customer satisfaction, they are poised to continue driving the industry forward and shaping the future of enameling technology.