Table of Contents

Advantages of Using Aluminum Wire in Wire Cable Making Machines

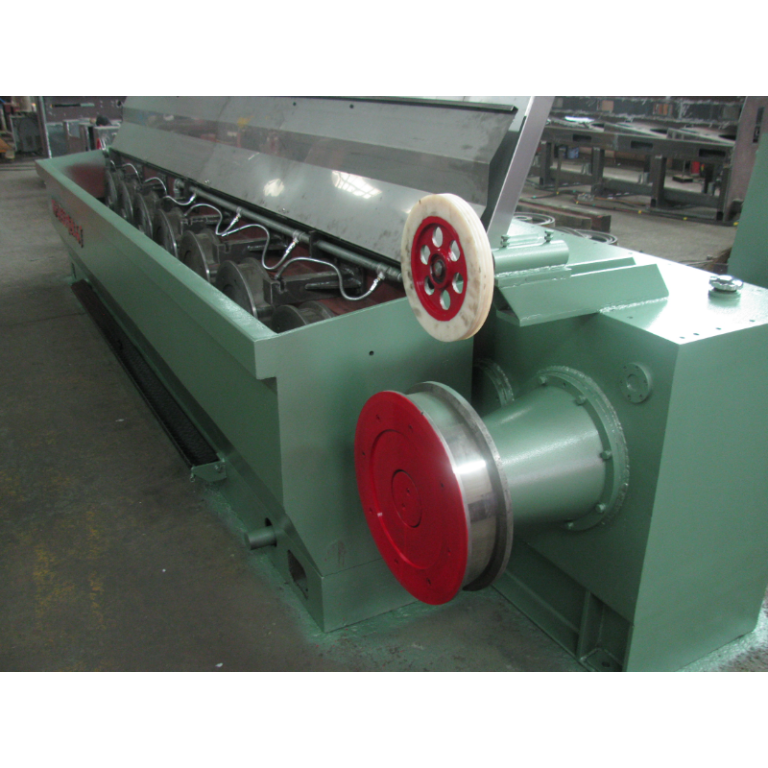

Aluminum Wire Drawing Machine for Wire Cable Making Production Line due to its numerous advantages. One of the main benefits of using aluminum wire is its lightweight nature. This makes it easier to handle and transport, reducing the strain on workers and machinery. Additionally, aluminum wire is more cost-effective than copper wire, making it a budget-friendly option for manufacturers.

In addition to being lightweight and cost-effective, aluminum wire is also highly conductive. This means that it can efficiently transmit electricity, making it ideal for use in wire cable making machines. Its high conductivity also results in lower energy losses, which can lead to increased efficiency and cost savings for manufacturers.

Another advantage of using Aluminum Wire Breakdown Machine is its corrosion resistance. Aluminum wire is naturally resistant to corrosion, making it a durable and long-lasting option for use in harsh environments. This can help to extend the lifespan of wire cable making machines and reduce maintenance costs over time.

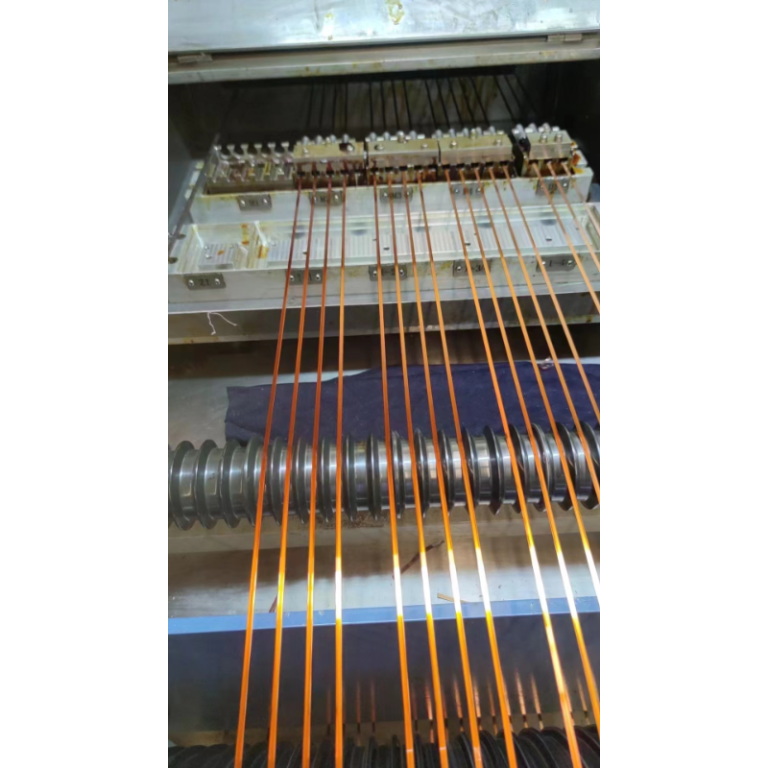

Furthermore, aluminum wire is easy to work with and can be easily shaped and formed to meet the specific requirements of wire cable making machines. This flexibility allows manufacturers to create custom cables and wires for a wide range of applications, from telecommunications to automotive industries.

In addition to its physical properties, aluminum wire is also environmentally friendly. Aluminum is a highly recyclable material, with nearly 75% of all aluminum ever produced still in use today. This makes it a sustainable choice for manufacturers looking to reduce their environmental impact and carbon footprint.

Overall, the advantages of using aluminum wire in wire cable making machines are clear. Its lightweight nature, cost-effectiveness, high conductivity, corrosion resistance, and environmental sustainability make it a versatile and practical option for manufacturers. By choosing aluminum wire, manufacturers can improve efficiency, reduce costs, and create high-quality cables and wires for a variety of applications.

Tips for Proper Maintenance and Care of Aluminum Wire in Wire Cable Making Machines

Aluminum wire is a popular choice for wire cable making machines due to its lightweight and corrosion-resistant properties. However, proper maintenance and care are essential to ensure the longevity and efficiency of the wire in these machines. In this article, we will discuss some tips for maintaining and caring for aluminum wire in wire cable making machines.

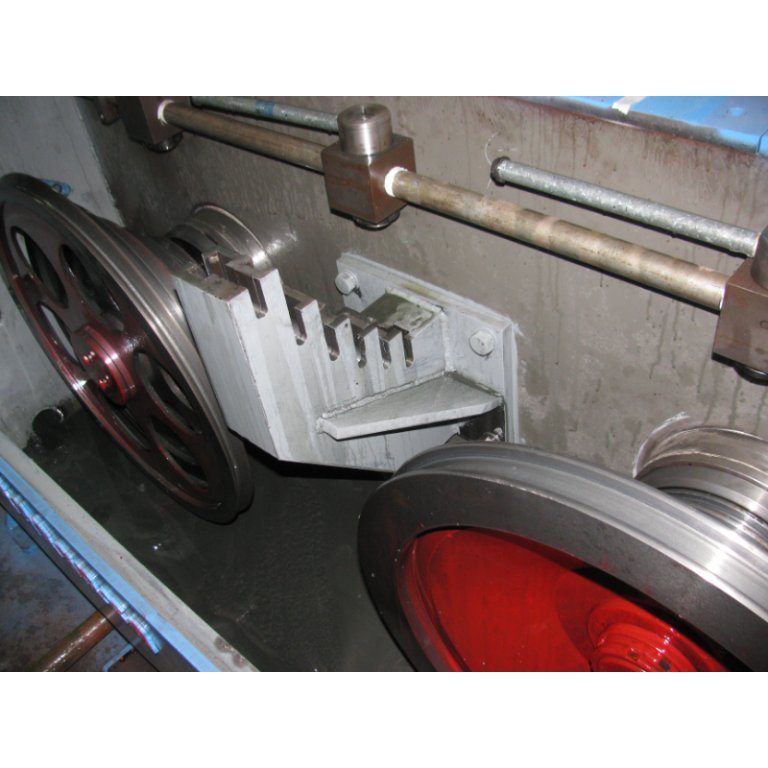

One of the most important aspects of maintaining Aluminum Alloy Wire Drawing Machine is to regularly inspect the wire for any signs of wear or damage. This can include checking for kinks, bends, or breaks in the wire. If any damage is found, it is important to replace the wire immediately to prevent further issues with the machine.

In addition to regular inspections, it is also important to clean the aluminum wire regularly to remove any dirt, debris, or other contaminants that may be present. This can be done using a mild detergent and water solution, followed by a thorough rinse and drying process. Keeping the wire clean will help to prevent corrosion and ensure smooth operation of the wire cable making machine.

Another important aspect of caring for aluminum wire in wire cable making machines is to properly store the wire when not in use. This includes keeping the wire in a dry, cool environment to prevent moisture buildup and corrosion. It is also important to store the wire in a way that prevents kinks or bends, as these can weaken the wire and lead to breakage during use.

When using aluminum wire in wire cable making machines, it is important to follow the manufacturer’s guidelines for proper use and operation. This can include using the correct size and type of wire for the machine, as well as following any recommended maintenance procedures. By following these guidelines, you can help to ensure the longevity and efficiency of the aluminum wire in your wire cable making machine.

In addition to following manufacturer guidelines, it is also important to regularly lubricate the wire cable making machine to prevent friction and wear on the aluminum wire. This can be done using a lubricant specifically designed for use with aluminum wire, and should be done on a regular basis to ensure smooth operation of the machine.

Finally, it is important to monitor the performance of the aluminum wire in the wire cable making machine on a regular basis. This can include checking for any changes in tension, speed, or other factors that may indicate a problem with the wire. By monitoring the performance of the wire, you can quickly identify and address any issues before they become more serious.

In conclusion, proper maintenance and care of aluminum wire in wire cable making machines is essential to ensure the longevity and efficiency of the wire. By following these tips, you can help to prevent damage and ensure smooth operation of your wire cable making machine for years to come.