Table of Contents

How to Optimize Efficiency in Automatic Enameling Production Lines

Automatic Enameling Machine have revolutionized the way in which enamel coatings are applied to various products, ranging from cookware to automotive parts. These automated systems offer numerous advantages, including increased efficiency, consistency, and quality control. However, in order to fully optimize the efficiency of automatic enameling production lines, it is essential to implement certain strategies and best practices.

One key factor in maximizing efficiency is proper maintenance of the equipment. Regular cleaning and maintenance of the enameling machines and associated components are crucial to ensure smooth operation and prevent downtime. This includes cleaning the spray nozzles, checking for any clogs or blockages, and replacing worn-out parts as needed. By staying on top of maintenance tasks, production downtime can be minimized, leading to increased overall efficiency.

Another important aspect of optimizing efficiency in automatic enameling production lines is proper training of personnel. Operators should be well-trained in the operation of the equipment, as well as in troubleshooting common issues that may arise. By providing comprehensive training to employees, the likelihood of errors and downtime is reduced, leading to a more efficient production process.

In addition to maintenance and training, it is also important to carefully monitor and analyze production data. By tracking key performance indicators such as cycle times, reject rates, and overall equipment effectiveness, managers can identify areas for improvement and implement targeted solutions. For example, if a particular machine is consistently experiencing downtime, adjustments can be made to the production schedule or maintenance procedures to address the issue.

Furthermore, implementing a proactive approach to quality control is essential for optimizing efficiency in automatic Enameling Coating Machine. By conducting regular quality checks throughout the production process, defects can be identified and corrected early on, preventing the need for rework or scrap. This not only saves time and resources but also ensures that the final product meets the required quality standards.

Another strategy for maximizing efficiency is to streamline the production process wherever possible. This may involve reorganizing workstations, optimizing material flow, or implementing lean manufacturing principles. By eliminating unnecessary steps and reducing waste, production throughput can be increased, leading to higher overall efficiency.

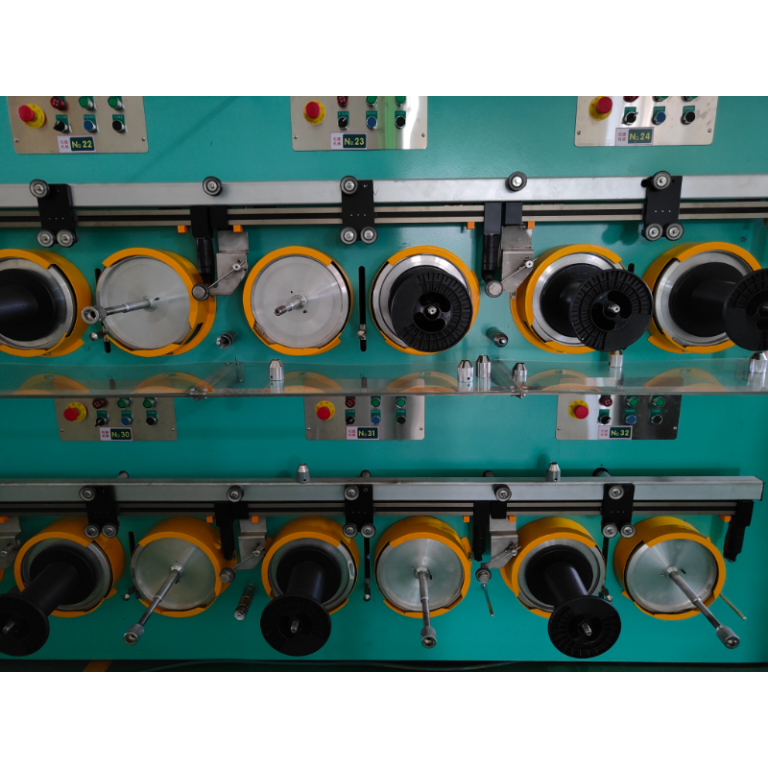

Furthermore, investing in advanced technology and automation can also help to optimize efficiency in automatic enameling production lines. Upgrading to state-of-the-art equipment with advanced features such as robotic arms, computerized control systems, and real-time monitoring capabilities can significantly improve productivity and reduce the risk of errors. By leveraging the latest technology, manufacturers can stay ahead of the competition and achieve higher levels of efficiency.

In conclusion, optimizing efficiency in automatic enameling production lines requires a combination of proper maintenance, training, data analysis, quality control, process optimization, and technology investment. By implementing these strategies and best practices, manufacturers can maximize productivity, reduce costs, and deliver high-quality products to customers. Ultimately, a well-optimized production line is essential for staying competitive in today’s fast-paced manufacturing industry.

Benefits of Implementing Automatic Enameling Production Lines

In today’s fast-paced manufacturing industry, efficiency and productivity are key factors in staying competitive. One way that companies are achieving this is by implementing automatic enameling production lines. These automated systems offer a wide range of benefits that can help businesses streamline their operations and improve their bottom line.

One of the primary advantages of automatic Enameling Wire Production Line is the increase in production speed. By automating the enameling process, companies can significantly reduce the time it takes to coat their products, allowing them to produce more in less time. This not only helps meet customer demand more quickly but also allows businesses to take on larger orders without sacrificing quality.

In addition to speed, automatic enameling production lines also offer improved consistency and quality control. Manual enameling processes are prone to human error, which can result in variations in the coating thickness or quality. By using automated systems, companies can ensure that each product is coated with the same level of precision and consistency, leading to higher-quality finished products that meet or exceed customer expectations.

Furthermore, automatic enameling production lines can help reduce waste and minimize material usage. These systems are designed to apply the enamel coating with maximum efficiency, ensuring that there is minimal overspray or excess material. This not only helps companies save money on materials but also reduces their environmental impact by minimizing waste and emissions.

Another benefit of implementing automatic enameling production lines is the reduction in labor costs. Manual enameling processes require a significant amount of labor to operate, monitor, and maintain. By automating these processes, companies can reduce their reliance on manual labor, freeing up employees to focus on more skilled tasks that add value to the business. This can lead to cost savings in the long run and help companies remain competitive in a global market.

Additionally, automatic enameling production lines offer improved safety for workers. Enameling processes can involve hazardous chemicals and high temperatures, which can pose risks to employees if not handled properly. By automating these processes, companies can minimize the exposure of workers to these hazards, creating a safer work environment and reducing the risk of accidents or injuries.

Overall, the benefits of implementing automatic enameling production lines are clear. From increased production speed and consistency to reduced waste and labor costs, these systems offer a wide range of advantages that can help companies improve their efficiency, quality, and profitability. By investing in automation, businesses can stay ahead of the competition and position themselves for long-term success in the manufacturing industry.