Table of Contents

Tips for Maintaining and Troubleshooting Aluminum Wire Cable Drawing Machine

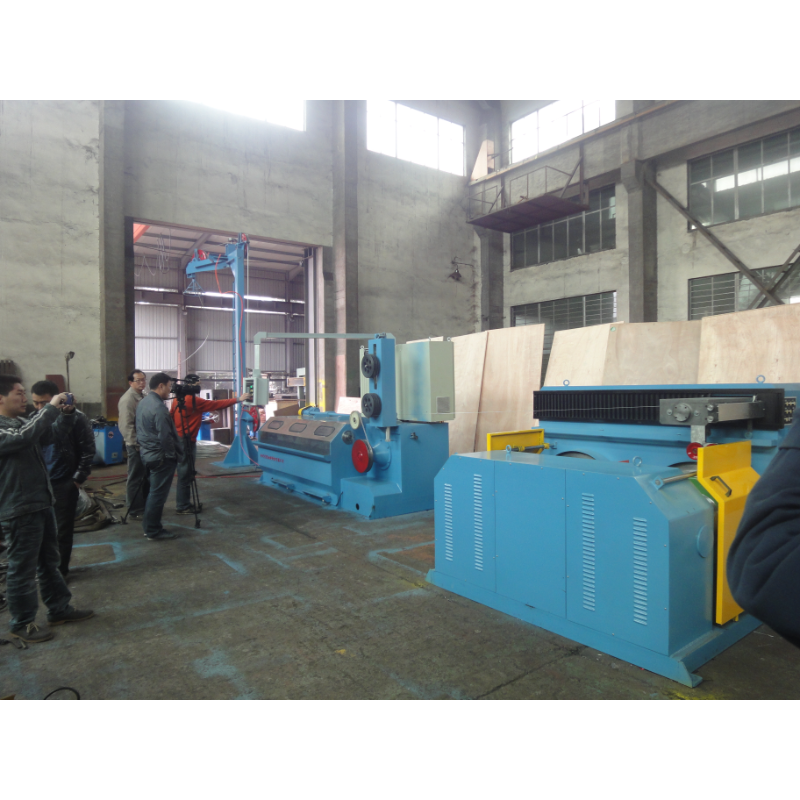

Aluminum Wire Drawing Machine for Wire Cable Making Production Line are essential equipment in the manufacturing industry for producing high-quality aluminum wire cables. These machines are used to pull aluminum wire through a series of dies to reduce its diameter and improve its strength and conductivity. To ensure the smooth operation of an aluminum wire cable drawing machine, regular maintenance and troubleshooting are necessary.

One of the most important tips for maintaining an aluminum wire cable drawing machine is to keep it clean and well-lubricated. Dirt, dust, and debris can build up on the machine’s components, causing friction and wear. Regular cleaning with a soft brush and a mild detergent can help prevent this buildup. Additionally, lubricating the machine’s moving parts with a high-quality lubricant can reduce friction and extend the machine’s lifespan.

Another important maintenance tip is to regularly inspect the machine’s components for signs of wear or damage. Check the dies, rollers, and bearings for any cracks, dents, or other defects that could affect the machine’s performance. Replace any worn or damaged parts immediately to prevent further damage to the machine.

In addition to regular maintenance, troubleshooting is also an essential part of keeping an Aluminum Fine Wire Drawing Machine running smoothly. One common issue that can arise with these machines is uneven wire drawing. This can be caused by a variety of factors, such as worn dies, improper lubrication, or incorrect tension settings. To troubleshoot this issue, check the dies for wear, lubricate the machine’s moving parts, and adjust the tension settings as needed.

Another common issue with aluminum wire cable drawing machines is wire breakage. This can be caused by a variety of factors, such as improper tension settings, worn dies, or a dirty machine. To troubleshoot this issue, check the tension settings, inspect the dies for wear, and clean the machine thoroughly to remove any dirt or debris that could be causing the wire to break.

It is also important to regularly monitor the machine’s performance and make adjustments as needed. Keep an eye on the machine’s speed, tension, and temperature to ensure that it is operating within the recommended parameters. If you notice any abnormalities in the machine’s performance, such as unusual noises or vibrations, address them immediately to prevent further damage to the machine.

In conclusion, maintaining and troubleshooting an aluminum wire cable drawing machine is essential for ensuring its smooth operation and longevity. By following these tips and regularly inspecting and cleaning the machine, you can prevent issues from arising and keep your machine running at its best. Remember to always consult the manufacturer’s guidelines for maintenance and troubleshooting to ensure that you are taking the proper steps to care for your machine.

Benefits of Using Aluminum Wire Cable Drawing Machine

Aluminum Wire Breakdown Machine is essential tools in the manufacturing industry for producing high-quality aluminum wire cables. These machines are designed to efficiently draw aluminum wire through a series of dies to reduce its diameter and improve its mechanical properties. There are several benefits to using an aluminum wire cable drawing machine, including increased productivity, improved quality, and cost savings.

One of the primary benefits of using an aluminum wire cable drawing machine is increased productivity. These machines are capable of drawing aluminum wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help companies meet tight production deadlines and fulfill customer orders quickly and efficiently. Additionally, the consistent and uniform drawing process ensures that each wire cable meets the required specifications, reducing the need for rework and increasing overall productivity.

Another benefit of using an aluminum wire cable drawing machine is improved quality. The drawing process helps to refine the structure of the aluminum wire, making it stronger and more durable. This results in wire cables that are less likely to break or fail under stress, increasing the reliability and longevity of the final product. Additionally, the uniform diameter and smooth surface finish achieved through the drawing process improve the electrical conductivity of the wire, making it ideal for use in a wide range of applications.

Cost savings are also a significant benefit of using an aluminum wire cable drawing machine. By producing high-quality wire cables efficiently, manufacturers can reduce waste and minimize production costs. The increased productivity of these machines allows companies to meet production targets with fewer resources, saving time and money in the long run. Additionally, the improved quality of the wire cables reduces the likelihood of defects or failures, further reducing costs associated with rework or warranty claims.

In addition to these benefits, aluminum wire cable drawing machines offer versatility and flexibility in the manufacturing process. These machines can be easily adjusted to accommodate different wire diameters and specifications, allowing manufacturers to produce a wide range of wire cables for various applications. This flexibility enables companies to respond quickly to changing market demands and customer requirements, ensuring that they remain competitive in the industry.

Overall, the benefits of using an aluminum wire cable drawing machine are clear. Increased productivity, improved quality, cost savings, and versatility make these machines essential tools for manufacturers in the wire and cable industry. By investing in a high-quality drawing machine, companies can enhance their production processes, increase efficiency, and deliver superior products to their customers. With the right equipment and expertise, manufacturers can take advantage of all the benefits that aluminum wire cable drawing machines have to offer.