Table of Contents

Top Features to Look for in a High-Quality Copper Wire Drawing Machine

When it comes to selecting a copper wire drawing machine for your business, it is crucial to choose a high-quality machine that can meet your production needs efficiently and effectively. With so many options available in the market, it can be overwhelming to decide which machine is the best fit for your requirements. To help you make an informed decision, we have compiled a list of the top features to look for in a high-quality copper wire drawing machine.

One of the most important features to consider when choosing a copper wire drawing machine is the material used in its construction. High-quality machines are typically made from durable materials such as stainless steel or high-grade aluminum, which ensures longevity and reliability. These materials are resistant to corrosion and wear, making them ideal for heavy-duty industrial use.

Another key feature to look for in a copper wire drawing machine is the motor power. The motor is responsible for driving the wire through the drawing dies, so it is essential to choose a machine with a powerful motor that can handle the workload efficiently. A high-quality machine will have a motor with sufficient horsepower to draw the wire at the desired speed and tension, resulting in consistent and precise wire production.

In addition to motor power, it is important to consider the speed and capacity of the machine. High-quality Copper Wire Drawing Machine for Rod Breakdown Machine are capable of drawing wire at varying speeds to accommodate different wire diameters and production requirements. Look for a machine that offers adjustable speed settings and a wide range of wire diameters to ensure versatility and flexibility in your production process.

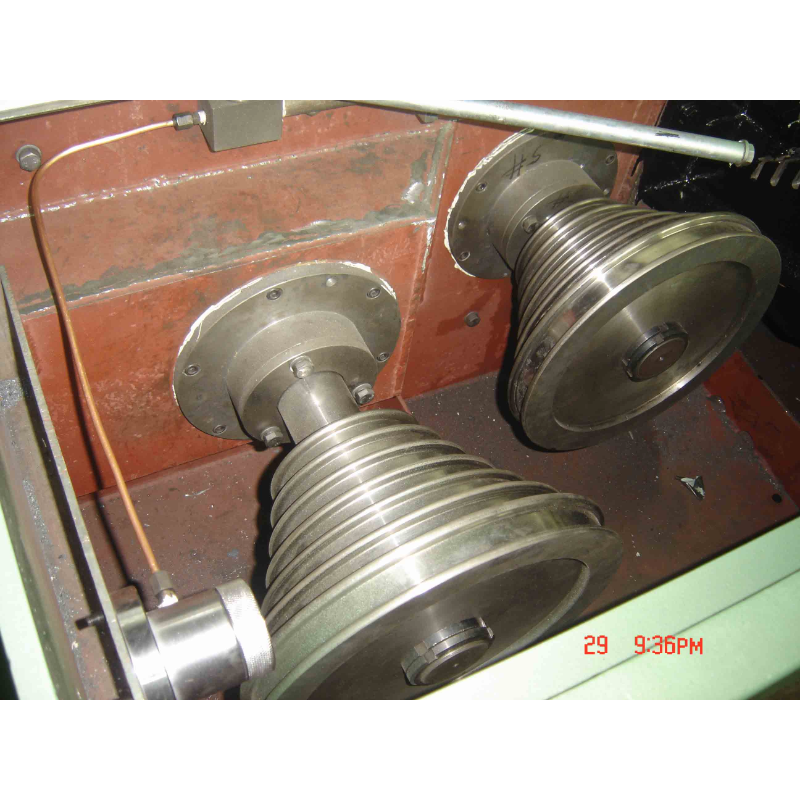

Furthermore, the number of drawing dies in the machine is another important feature to consider. The more drawing dies a machine has, the more stages of drawing the wire can undergo, resulting in a smoother and more uniform wire finish. A high-quality copper wire drawing machine will have multiple drawing dies that can be easily adjusted to achieve the desired wire diameter and finish.

Ease of operation and maintenance is also a crucial factor to consider when choosing a copper wire drawing machine. Look for a machine that is user-friendly and comes with clear instructions for setup and operation. Additionally, choose a machine that is easy to clean and maintain, as regular maintenance is essential to ensure the longevity and performance of the machine.

Finally, consider the reputation of the manufacturer when selecting a copper wire drawing machine. Choose a machine from a reputable manufacturer with a proven track record of producing high-quality machines that meet industry standards. A reliable manufacturer will provide excellent customer support and service, ensuring that your machine operates smoothly and efficiently.

In conclusion, selecting a high-quality copper wire drawing machine is essential for achieving consistent and precise wire production. By considering the features mentioned above, you can choose a machine that meets your production needs and ensures reliable performance. Invest in a top-quality copper wire drawing machine from a reputable manufacturer to enhance the efficiency and productivity of your business operations.

Benefits of Using Copper Wire Drawing Machines in Manufacturing

Copper wire drawing machines play a crucial role in the manufacturing industry, especially in the production of electrical wiring, cables, and other copper-based products. These machines are designed to pull copper wire through a series of dies to reduce its diameter and improve its quality. By using Copper Rod Casting and Making Machine, manufacturers can achieve precise dimensions, smooth surfaces, and high tensile strength in their copper wire products.

One of the key benefits of using copper wire drawing machines is the ability to control the diameter of the wire with precision. These machines are equipped with multiple dies of varying sizes, allowing manufacturers to produce copper wire in different gauges to meet specific requirements. Whether it’s thin wire for delicate electronics or thick wire for industrial applications, copper wire drawing machines can easily accommodate a wide range of wire diameters.

In addition to controlling the diameter of the wire, copper wire drawing machines also help improve the surface finish of the copper wire. As the wire is pulled through the dies, any imperfections or impurities on the surface are smoothed out, resulting in a clean and polished finish. This is essential for applications where the appearance of the copper wire is important, such as in decorative lighting fixtures or jewelry.

Furthermore, copper wire drawing machines can enhance the tensile strength of the copper wire. By subjecting the wire to a series of drawing passes, the grains in the copper are elongated and aligned in the direction of the wire, making it stronger and more durable. This is particularly beneficial for applications where the copper wire will be subjected to high stress or tension, such as in overhead power lines or automotive wiring harnesses.

Another advantage of using copper wire drawing machines is the ability to increase the length of the wire without compromising its quality. By continuously drawing the wire through the dies, manufacturers can produce long lengths of copper wire with consistent dimensions and properties. This is essential for applications where uninterrupted lengths of wire are required, such as in telecommunications cables or industrial machinery.

Moreover, copper wire drawing machines are highly efficient and cost-effective. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of copper wire in a short amount of time. This not only increases productivity but also reduces production costs, making copper wire drawing machines a valuable investment for manufacturers looking to improve their bottom line.

In conclusion, copper wire drawing machines offer a wide range of benefits for manufacturers in the production of copper wire products. From controlling the diameter and surface finish of the wire to enhancing its tensile strength and length, these machines play a crucial role in ensuring the quality and consistency of copper wire. With their efficiency and cost-effectiveness, copper wire drawing machines are an essential tool for any manufacturer looking to achieve superior results in their copper wire production.