Table of Contents

Advantages of Using Rod Breakdown Machine for Copper Wire Production

Copper wire is a crucial component in various industries, including telecommunications, electronics, and power distribution. To meet the growing demand for copper wire, manufacturers rely on efficient machinery to produce high-quality products. One such machine that plays a vital role in the production process is the rod breakdown machine.

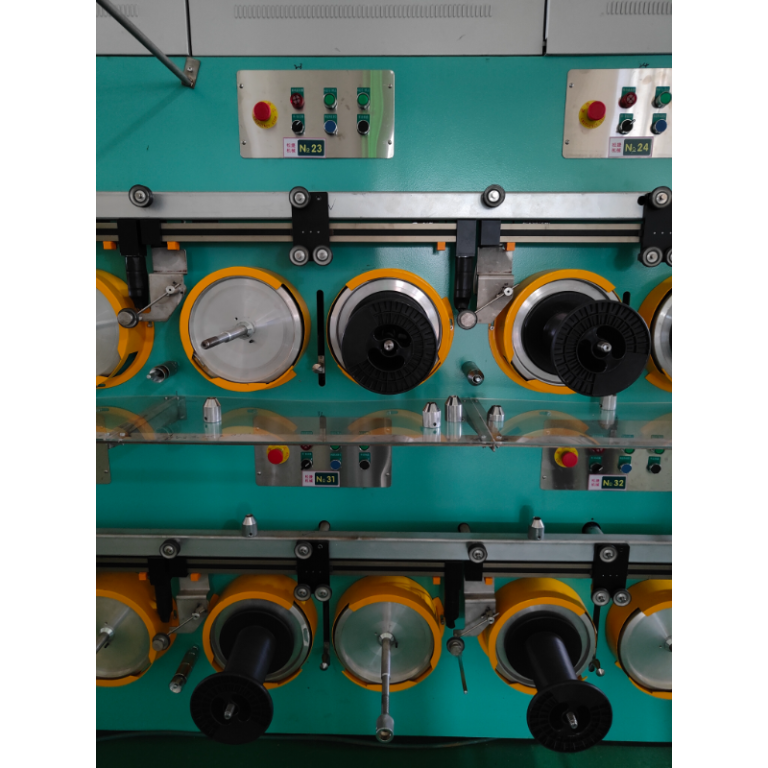

The rod breakdown machine is specifically designed to reduce the diameter of copper rods to the desired size for wire drawing. This machine is essential in the initial stages of copper wire production, as it helps in preparing the raw material for further processing. There are several advantages to using a rod breakdown machine for copper wire production.

First and foremost, the rod breakdown machine is highly efficient in reducing the diameter of copper rods. This machine can process large quantities of copper rods quickly and accurately, ensuring a consistent diameter throughout the production process. This efficiency helps manufacturers meet tight production deadlines and maintain high-quality standards.

Additionally, the rod breakdown machine is versatile and can handle a wide range of copper rod sizes. This flexibility allows manufacturers to produce different types of copper wire with varying diameters, catering to the diverse needs of their customers. Whether it is thin gauge wire for electronics or thick gauge wire for power distribution, the rod breakdown machine can accommodate various specifications.

Moreover, the rod breakdown machine is equipped with advanced technology that ensures precision and accuracy in the wire reduction process. This technology includes sensors and controls that monitor and adjust the speed and tension of the copper rods, resulting in uniform wire diameter and smooth surface finish. This level of precision is crucial in producing high-quality copper wire that meets industry standards.

Another advantage of using a rod breakdown machine is its cost-effectiveness. By automating the wire reduction process, manufacturers can save on labor costs and increase production efficiency. The machine’s high throughput and low maintenance requirements further contribute to cost savings, making it a valuable investment for copper wire manufacturers.

Furthermore, the rod breakdown machine is designed for durability and reliability, ensuring consistent performance over an extended period. This reliability minimizes downtime and production interruptions, allowing manufacturers to meet customer demands without delays. Additionally, the machine’s robust construction and quality components contribute to its longevity, providing a long-term solution for copper wire production.

In conclusion, the rod breakdown machine offers several advantages for copper wire production, including efficiency, versatility, precision, cost-effectiveness, and reliability. By investing in this essential machinery, manufacturers can streamline their production process, improve product quality, and meet customer demands effectively. As the demand for copper wire continues to grow, the rod breakdown machine remains a crucial asset for the industry.

Maintenance Tips for Rod Breakdown Machine to Ensure Longevity

A rod breakdown machine is a crucial piece of equipment in the wire manufacturing industry, particularly for producing copper wire. This machine is responsible for reducing the diameter of copper rods to the desired size, which is essential for creating high-quality wire products. To ensure the longevity and optimal performance of a rod breakdown machine, proper maintenance is key.

Regular maintenance of a rod breakdown machine involves several important steps. One of the most critical aspects of maintenance is keeping the machine clean and free of debris. Over time, dust, dirt, and other contaminants can build up on the machine’s components, leading to increased wear and tear. Regularly cleaning the machine with a soft brush or cloth can help prevent this buildup and prolong the machine’s lifespan.

In addition to keeping the machine clean, it is essential to regularly inspect and lubricate its moving parts. The bearings, gears, and other components of a rod breakdown machine are subject to a significant amount of friction during operation, which can lead to wear and tear over time. By inspecting these parts regularly and applying lubricant as needed, you can help reduce friction and prevent premature failure of the machine.

Another important aspect of maintenance for a rod breakdown machine is monitoring its electrical components. Electrical issues can cause serious problems for the machine, including malfunctions and breakdowns. Regularly inspecting the machine’s wiring, connections, and electrical components can help identify and address any potential issues before they escalate.

In addition to these regular maintenance tasks, it is also important to schedule periodic maintenance checks by a qualified technician. A professional technician can perform more in-depth inspections and maintenance tasks that may be beyond the scope of regular maintenance. These checks can help identify any potential issues early on and prevent costly repairs down the line.

When it comes to maintaining a rod breakdown machine, prevention is key. By staying on top of regular maintenance tasks and addressing any issues promptly, you can help ensure the longevity and optimal performance of your machine. Investing time and resources in proper maintenance now can save you time and money in the long run by preventing costly repairs and downtime.

In conclusion, proper maintenance is essential for ensuring the longevity and optimal performance of a rod breakdown machine. By keeping the machine clean, inspecting and lubricating its moving parts, monitoring its electrical components, and scheduling periodic maintenance checks, you can help prevent premature wear and tear and extend the life of your machine. Investing in regular maintenance now can save you time and money in the long run by preventing costly repairs and downtime.

Comparison of Different Rod Breakdown Machine Models for Copper Wire Manufacturing

Rod breakdown machines are essential equipment in the manufacturing process of copper wire. These machines are used to reduce the diameter of copper rods to the desired size for further processing. There are several models of rod breakdown machines available in the market, each with its own unique features and capabilities. In this article, we will compare different rod breakdown machine models for copper wire manufacturing to help you make an informed decision when choosing the right machine for your production needs.

One of the key factors to consider when comparing rod breakdown machine models is the maximum rod diameter that can be processed. Some machines are designed to handle smaller diameter rods, while others are capable of processing larger diameter rods. The maximum rod diameter that a machine can handle will determine the range of wire sizes that can be produced. It is important to choose a machine that can accommodate the diameter of rods you will be working with in your production process.

Another important factor to consider is the speed at which the machine can operate. The production efficiency of a rod breakdown machine is directly related to its processing speed. Machines with higher processing speeds can produce more wire in a shorter amount of time, increasing overall productivity. However, it is important to balance speed with quality to ensure that the wire produced meets the required specifications.

In addition to maximum rod diameter and processing speed, it is also important to consider the number of drawing dies that a rod breakdown machine is equipped with. Drawing dies are used to reduce the diameter of the rod in stages, resulting in a smoother and more uniform wire. Machines with a higher number of drawing dies are capable of producing wire with a higher level of precision and consistency. This is particularly important for applications that require high-quality wire with tight tolerances.

Furthermore, the power consumption of a rod breakdown machine is an important consideration when comparing different models. Machines with higher power consumption may result in higher operating costs over time. It is important to choose a machine that is energy-efficient to minimize operating expenses and reduce the environmental impact of your production process.

When comparing rod breakdown machine models, it is also important to consider the overall build quality and durability of the machine. Machines that are built with high-quality materials and components are more likely to withstand the rigors of continuous operation and require less maintenance over time. Investing in a durable machine can help reduce downtime and increase the overall lifespan of the equipment.

In conclusion, there are several factors to consider when comparing different rod breakdown machine models for copper wire manufacturing. These factors include maximum rod diameter, processing speed, number of drawing dies, power consumption, and build quality. By carefully evaluating these factors, you can choose the right machine for your production needs and ensure that your manufacturing process runs smoothly and efficiently.