Table of Contents

Maintenance Tips for Aluminum Sheet Wire Drawing Machine

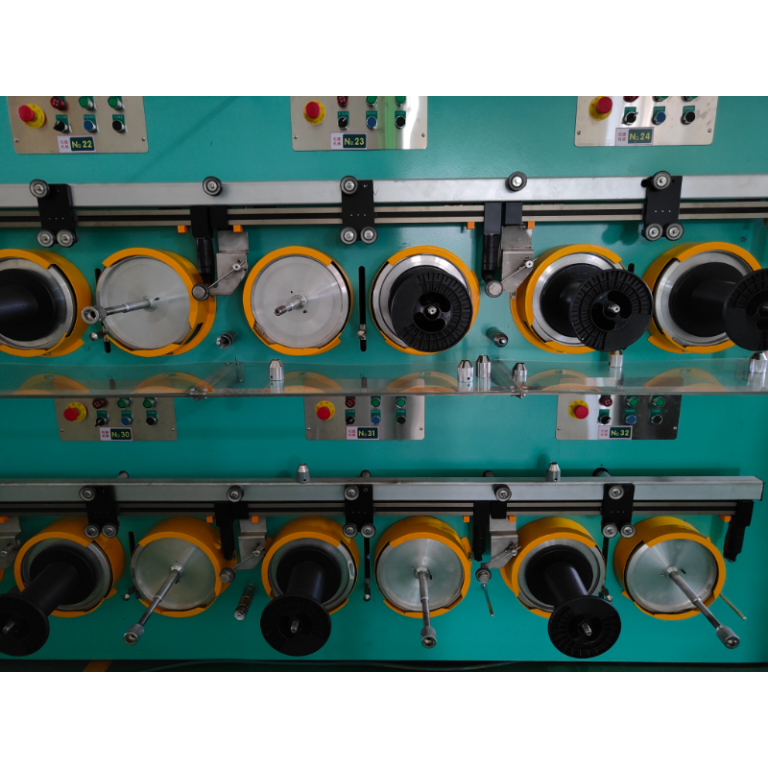

Aluminum sheet wire drawing machines are essential equipment in the manufacturing industry, used to produce high-quality aluminum wires for various applications. To ensure the smooth operation and longevity of these machines, proper maintenance is crucial. In this article, we will discuss some maintenance tips for aluminum sheet wire drawing machines.

Regular cleaning of the machine is essential to prevent the buildup of dirt, dust, and debris, which can affect the machine’s performance. Use a soft brush or cloth to clean the machine’s exterior and interior components, such as the wire drawing dies, rollers, and guides. Make sure to remove any accumulated dirt and lubricant residue to prevent corrosion and wear.

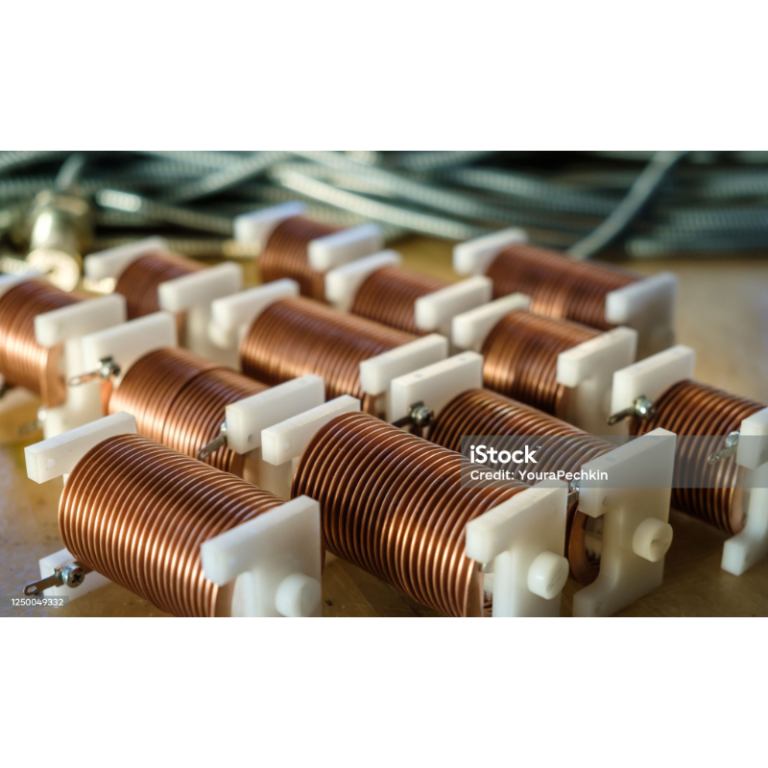

Inspect the machine’s components regularly for signs of wear and tear, such as cracks, dents, or deformation. Replace any damaged parts immediately to prevent further damage to the machine and ensure smooth operation. Pay special attention to the wire drawing dies, as they are critical components that directly affect the quality of the Aluminum Fine Wire Drawing Machine produced.

Check the machine’s lubrication system regularly to ensure that all moving parts are properly lubricated. Insufficient lubrication can cause friction and wear on the machine’s components, leading to decreased performance and potential breakdowns. Use the recommended lubricants and follow the manufacturer’s guidelines for lubrication intervals to keep the machine running smoothly.

Monitor the machine’s electrical system for any signs of malfunction, such as overheating, sparking, or unusual noises. Electrical issues can cause serious damage to the machine and pose a safety hazard to operators. If you notice any abnormalities, immediately shut down the machine and contact a qualified technician for inspection and repair.

Calibrate the machine regularly to ensure accurate wire diameter and quality. Use a micrometer or other measuring tools to check the wire diameter produced by the machine and make adjustments as needed. Proper calibration is essential for producing high-quality aluminum wire that meets industry standards and customer requirements.

Keep a record of the machine’s maintenance activities, including cleaning, inspections, repairs, and calibrations. This will help you track the machine’s performance over time and identify any recurring issues that may require attention. Regular maintenance records can also be useful for scheduling preventive maintenance tasks and planning for future upgrades or replacements.

Train operators and maintenance personnel on proper machine operation and maintenance procedures. Proper training can help prevent accidents, reduce downtime, and extend the machine’s lifespan. Make sure that all personnel are familiar with the machine’s safety features, operating instructions, and maintenance requirements.

In conclusion, proper maintenance is essential for ensuring the smooth operation and longevity of aluminum sheet wire drawing machines. By following these maintenance tips, you can keep your machine in top condition and produce high-quality aluminum wire for your manufacturing needs. Remember to clean the machine regularly, inspect and replace damaged parts, lubricate moving components, monitor the electrical system, calibrate the machine, keep maintenance records, and train personnel on proper machine operation. With proper maintenance, your aluminum sheet wire drawing machine will continue to perform efficiently and reliably for years to come.

How to Choose the Right Aluminum Sheet Wire Drawing Machine for Your Business

Aluminum sheet wire drawing machines are essential equipment for businesses involved in the production of aluminum products. These machines are used to reduce the diameter of aluminum wire or rod by pulling it through a series of dies, resulting in a smoother surface finish and improved mechanical properties. Choosing the right Aluminum Alloy Wire Drawing Machine for your business is crucial to ensure efficient production and high-quality output.

When selecting an aluminum sheet wire drawing machine, there are several factors to consider. The first consideration is the type of material you will be working with. Aluminum wire drawing machines are designed to handle different types of aluminum alloys, so it is important to choose a machine that is compatible with the specific alloy you will be using. Additionally, consider the diameter of the wire or rod you will be drawing, as different machines are designed to handle different sizes.

Another important factor to consider when choosing an aluminum sheet wire drawing machine is the speed and capacity of the machine. The speed at which the machine can draw the wire or rod will impact the production efficiency of your business. Additionally, consider the capacity of the machine in terms of the maximum diameter and length of wire or rod it can handle. Choosing a machine with the right speed and capacity for your production needs will help ensure smooth and efficient operation.

It is also important to consider the quality and durability of the machine when making your selection. Look for a machine that is made from high-quality materials and has a solid construction to ensure long-term reliability and performance. Additionally, consider the reputation of the manufacturer and read reviews from other customers to gauge the quality of the machine.

When choosing an aluminum sheet wire drawing machine, it is also important to consider the features and capabilities of the machine. Look for a machine that offers a range of drawing dies to accommodate different wire or rod sizes. Additionally, consider whether the machine offers features such as automatic lubrication systems, digital controls, and safety features to enhance efficiency and safety in your production process.

Finally, consider the cost of the machine and your budget constraints when making your selection. While it is important to invest in a high-quality machine that meets your production needs, it is also important to consider the overall cost of the machine and whether it fits within your budget. Compare prices from different manufacturers and consider factors such as warranty, maintenance costs, and customer support when making your decision.

In conclusion, choosing the right aluminum sheet wire drawing machine for your business is a crucial decision that will impact the efficiency and quality of your production process. Consider factors such as material compatibility, speed and capacity, quality and durability, features and capabilities, and cost when making your selection. By carefully evaluating these factors and choosing a machine that meets your specific production needs, you can ensure smooth and efficient operation and high-quality output for your business.