Exploring the Benefits of Using Aluminum Wire Drawing Machine in Wire Cable Making Production Line

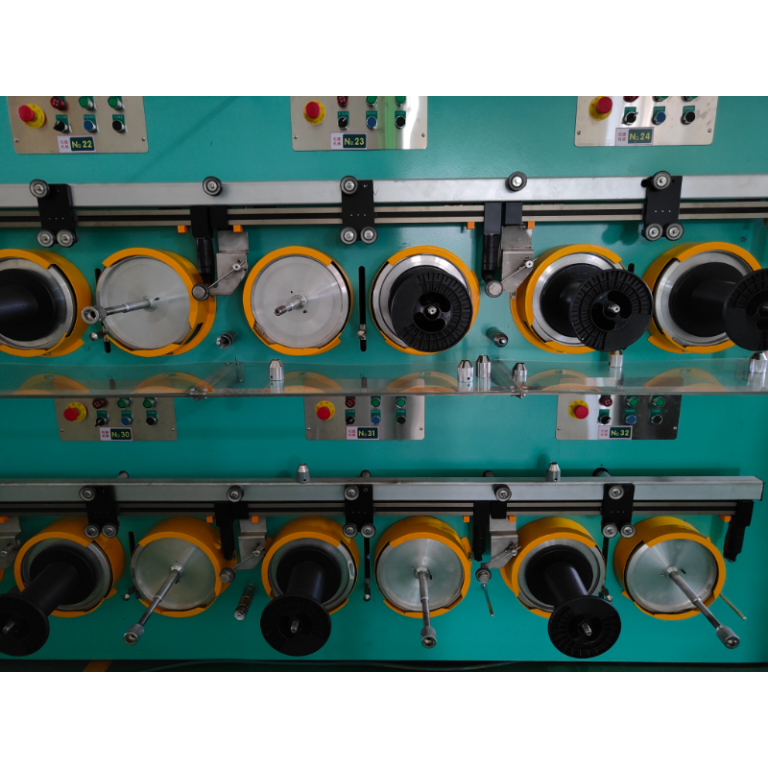

Aluminum wire drawing machines play a crucial role in the wire cable making production line. These machines are designed to efficiently reduce the diameter of aluminum wire by pulling it through a series of dies, resulting in a smoother and more uniform wire that is suitable for various applications. There are several benefits to using aluminum wire drawing machines in the production process.

One of the key advantages of using an aluminum wire drawing machine is the ability to control the diameter of the wire with precision. By adjusting the speed and tension of the machine, manufacturers can produce wire of different diameters to meet specific requirements. This level of control ensures that the wire meets the exact specifications needed for the final product, whether it is for electrical wiring, telecommunications cables, or other applications.

In addition to precise diameter control, Aluminum Sheet Wire Drawing Machine also help improve the surface finish of the wire. As the wire is pulled through the dies, any imperfections or irregularities on the surface are smoothed out, resulting in a cleaner and more uniform finish. This is essential for applications where the appearance of the wire is important, such as in decorative or architectural applications.

Another benefit of using aluminum wire drawing machines is the ability to increase the strength and ductility of the wire. As the wire is drawn through the dies, its grain structure is refined, which helps improve its mechanical properties. This makes the wire stronger and more flexible, making it suitable for a wider range of applications. Additionally, the drawing process can also help reduce the overall weight of the wire, making it more cost-effective and efficient to transport.

Furthermore, aluminum wire drawing machines are highly efficient and can process large quantities of wire in a relatively short amount of time. This helps manufacturers meet production deadlines and reduce lead times, ultimately improving overall productivity. Additionally, the machines are designed to be easy to operate and maintain, reducing downtime and increasing the longevity of the equipment.

Overall, the use of aluminum wire drawing machines in the wire cable making production line offers numerous benefits, including precise diameter control, improved surface finish, increased strength and ductility, and enhanced efficiency. These machines play a critical role in ensuring that the wire meets the required specifications for various applications, ultimately leading to high-quality products that meet customer expectations. By investing in aluminum wire drawing machines, manufacturers can improve their production processes and stay competitive in the market.