Table of Contents

Maintenance Tips for Aluminum Wire Making Machine In Factory

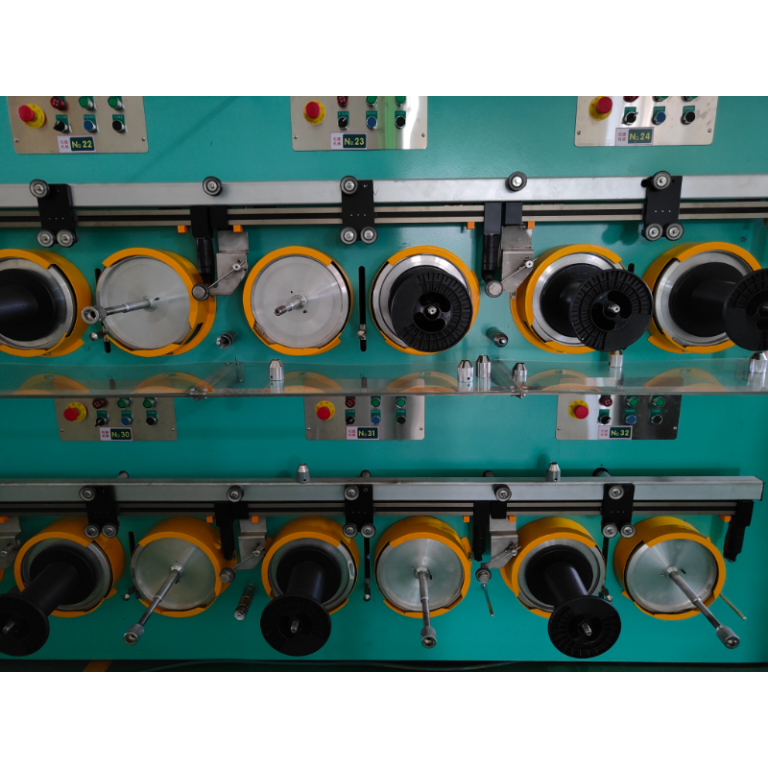

Aluminum wire drawing machines are essential equipment in the manufacturing industry, used to produce aluminum wires of various diameters for a wide range of applications. These machines are complex pieces of machinery that require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some maintenance tips for aluminum wire drawing machines to help you keep your equipment in top condition.

One of the most important maintenance tasks for aluminum wire drawing machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the machine. To prevent this, it is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the machine’s moving parts with a suitable lubricant can help reduce friction and prolong the life of the equipment.

Another crucial maintenance tip for Aluminum Wire Breakdown Machine is to inspect the machine’s components regularly for signs of wear or damage. Check the machine’s rollers, bearings, and other moving parts for any signs of wear, such as cracks, dents, or corrosion. Replace any damaged components immediately to prevent further damage to the machine and ensure smooth operation. Additionally, check the machine’s electrical components, such as wiring and connections, for any signs of wear or damage. Faulty electrical components can lead to malfunctions and pose a safety hazard, so it is essential to address any issues promptly.

In addition to regular cleaning and inspection, it is essential to calibrate the machine regularly to ensure accurate wire diameter and quality. Over time, the machine’s calibration can drift, leading to inaccuracies in wire diameter and quality. To prevent this, it is crucial to calibrate the machine regularly using a calibrated gauge or micrometer. This will help ensure that the machine produces wires of the desired diameter and quality consistently.

Furthermore, it is essential to follow the manufacturer’s recommended maintenance schedule for your Aluminum Wire Drawing Process. The manufacturer’s guidelines will provide you with specific instructions on how to maintain and care for your equipment properly. This may include recommendations for lubrication, cleaning, calibration, and other maintenance tasks. By following the manufacturer’s guidelines, you can help prolong the life of your Aluminum Wire Drawing Machine and ensure optimal performance.

Lastly, it is essential to train your operators on proper machine maintenance and care. Proper training can help prevent operator errors that can lead to machine damage or malfunction. Ensure that your operators are familiar with the machine’s operation and maintenance procedures, and provide them with the necessary tools and resources to perform maintenance tasks effectively. By investing in operator training, you can help ensure that your aluminum wire drawing machine operates efficiently and reliably.

In conclusion, proper maintenance is essential for ensuring the optimal performance and longevity of aluminum wire drawing machines. By following these maintenance tips, you can help keep your equipment in top condition and prevent costly repairs or downtime. Regular cleaning, inspection, calibration, following the manufacturer’s guidelines, and operator training are all crucial aspects of maintaining aluminum wire drawing machines. By incorporating these maintenance tips into your regular maintenance routine, you can help prolong the life of your equipment and ensure consistent, high-quality wire production.

Advantages of Using Aluminum Wire Drawing Machines

Aluminum wire drawing machines are essential tools in the manufacturing industry for producing high-quality aluminum wires of various sizes and shapes. These machines offer numerous advantages that make them a preferred choice for many manufacturers. In this article, we will explore the advantages of using aluminum wire drawing machines and how they can benefit your production process.

One of the primary advantages of using aluminum wire drawing machines is their ability to produce wires with precise dimensions. These machines are equipped with advanced technology that allows for accurate control over the diameter and shape of the wire being produced. This precision is crucial for ensuring that the final product meets the required specifications and standards.

Additionally, Aluminum Fine Wire Drawing Machine are highly efficient in terms of production output. These machines are capable of drawing aluminum wires at high speeds, allowing for increased productivity and reduced production time. This efficiency is essential for meeting tight deadlines and keeping up with the demands of the market.

Another advantage of using aluminum wire drawing machines is their versatility. These machines can be used to produce wires of various sizes and shapes, making them suitable for a wide range of applications. Whether you need thin wires for electrical applications or thick wires for structural purposes, aluminum wire drawing machines can accommodate your needs.

Furthermore, aluminum wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous use in a manufacturing environment, ensuring long-term performance and minimal downtime. This reliability is essential for maintaining a smooth production process and avoiding costly interruptions.

In addition to their precision, efficiency, versatility, and durability, aluminum wire drawing machines also offer cost savings for manufacturers. These machines are designed to minimize material waste and energy consumption, resulting in lower production costs. By investing in aluminum wire drawing machines, manufacturers can improve their bottom line and remain competitive in the market.

Moreover, aluminum wire drawing machines are easy to operate and maintain, making them user-friendly for operators. These machines are equipped with intuitive controls and safety features that ensure smooth operation and minimize the risk of accidents. Additionally, routine maintenance tasks are straightforward and can be performed by trained personnel, reducing the need for specialized maintenance services.

Overall, the advantages of using aluminum wire drawing machines are clear. From their precision and efficiency to their versatility and durability, these machines offer numerous benefits for manufacturers looking to produce high-quality aluminum wires. By investing in aluminum wire drawing machines, manufacturers can improve their production process, reduce costs, and stay ahead of the competition in the market.

In conclusion, aluminum wire drawing machines are essential tools for manufacturers seeking to produce high-quality aluminum wires efficiently and cost-effectively. With their precision, efficiency, versatility, durability, and cost savings, these machines offer a range of advantages that can benefit any production process. If you are considering investing in aluminum wire drawing machines, now is the time to take advantage of these benefits and enhance your manufacturing capabilities.