مقارنة بين مختلف ونبسب؛آلات سحب الأسلاك النحاسية من النوع الرطب ونبسب؛ التصنيع

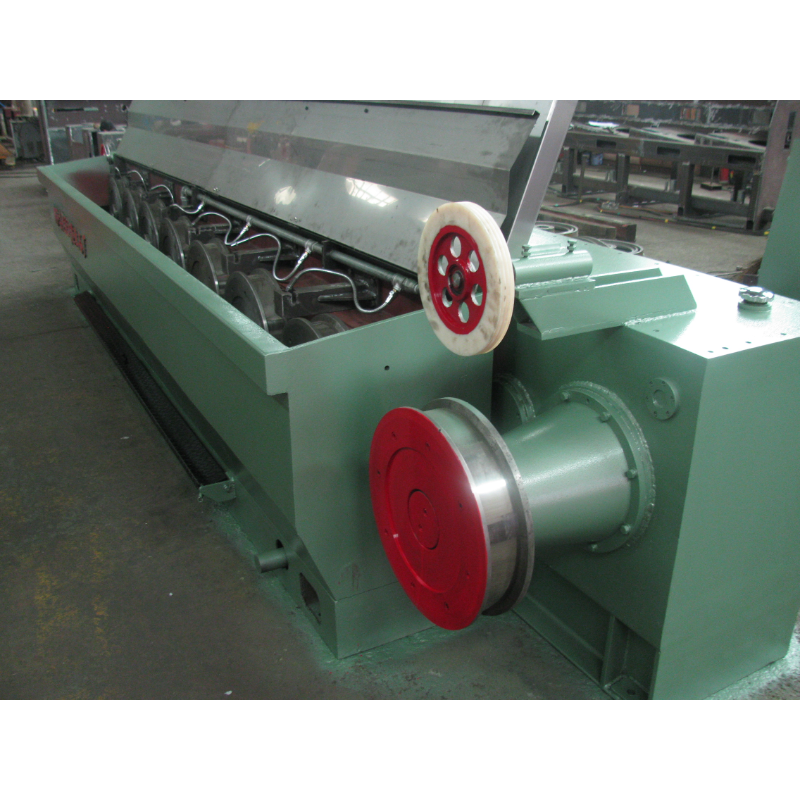

هناك عدة نماذج من آلات كسر القضبان المتوفرة في السوق، ولكل منها ميزاته وقدراته الفريدة. في هذه المقالة، سنقوم بمقارنة نماذج مختلفة من آلات سحب الأسلاك النحاسية لتصنيع آلات سحب الأسلاك النحاسية لمساعدتك على اتخاذ قرار مستنير عند اختيار الماكينة المناسبة لاحتياجات الإنتاج الخاصة بك.

أحد العوامل الرئيسية التي يجب مراعاتها عند مقارنة نماذج آلات تفكيك القضبان هو الحد الأقصى لقطر القضيب الذي يمكن للآلة التعامل معه. تم تصميم بعض الآلات للتعامل مع قضبان ذات قطر أصغر، في حين أن بعضها الآخر قادر على معالجة قضبان ذات قطر أكبر. سيحدد الحد الأقصى لقطر القضيب الذي يمكن للآلة التعامل معه نطاق أحجام الأسلاك التي يمكن إنتاجها. من المهم اختيار آلة يمكنها استيعاب قطر القضيب المناسب لمتطلبات الإنتاج الخاصة بك.

هناك عامل مهم آخر يجب مراعاته وهو السرعة التي يمكن أن تعمل بها الماكينة. ترتبط كفاءة الإنتاج لآلة تكسير القضبان بشكل مباشر بسرعة المعالجة. الآلات التي يمكنها العمل بسرعات أعلى ستكون قادرة على إنتاج المزيد من الأسلاك في فترة زمنية أقصر، مما يزيد من الإنتاجية الإجمالية. ومع ذلك، من المهم الموازنة بين السرعة والجودة للتأكد من أن السلك المنتج يلبي المواصفات المطلوبة.

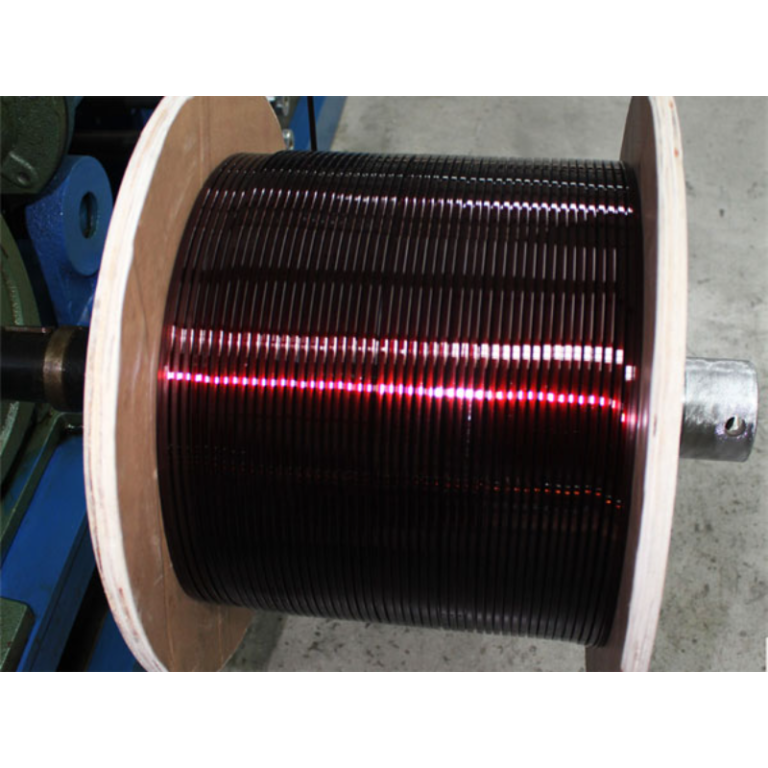

جودة السلك الذي تنتجه أ آلة انهيار قضبان الأسلاك النحاسية هو أيضًا عامل حاسم يجب مراعاته. يجب أن تكون الآلة قادرة على إنتاج سلك بقطر ثابت وسطح نهائي للوفاء بمعايير الجودة الخاصة بالصناعة. تم تجهيز بعض الآلات بميزات متقدمة مثل التحكم التلقائي في التوتر وأنظمة المراقبة لضمان جودة السلك المنتج. من المهم اختيار آلة يمكنها تقديم أداء ثابت وموثوق لتلبية متطلبات عملائك.

بالإضافة إلى المواصفات الفنية للآلة، من المهم أيضًا مراعاة التكلفة الإجمالية للملكية. ولا يشمل ذلك سعر الشراء الأولي للآلة فحسب، بل يشمل أيضًا تكاليف الصيانة والتشغيل. قد تتطلب بعض الآلات صيانة متكررة أو تستهلك طاقة أكبر، مما قد يزيد من التكلفة الإجمالية للملكية. من المهم تقييم التكلفة الإجمالية للملكية على مدار عمر الماكينة لتحديد الخيار الأكثر فعالية من حيث التكلفة لاحتياجات الإنتاج الخاصة بك.

عند مقارنة نماذج مختلفة من آلات تفكيك القضبان، من المهم مراعاة سمعة الشركة المصنعة وموثوقيتها. اختر شركة مصنعة ذات سمعة طيبة تتمتع بسجل حافل في تقديم آلات عالية الجودة ودعم عملاء ممتاز. ستوفر إحدى الشركات المصنعة الموثوقة المساعدة الفنية وقطع الغيار ودعم الخدمة لضمان تشغيل جهازك بكفاءة وفعالية.

في الختام، يعد اختيار آلة تصنيع تفكيك القضبان المناسبة قرارًا حاسمًا يمكن أن يؤثر على إنتاجية وجودة عملية الإنتاج لديك. ضع في اعتبارك عوامل مثل الحد الأقصى لقطر القضيب، وسرعة المعالجة، وجودة السلك، وتكلفة الملكية، وسمعة الشركة المصنعة عند مقارنة نماذج الماكينات المختلفة. من خلال اتخاذ قرار مستنير، يمكنك التأكد من أن عملية الإنتاج الخاصة بك تسير بسلاسة وكفاءة، وتلبية متطلبات عملائك ومعايير الصناعة.