Table of Contents

Maintenance Tips for Automatic Aluminum Wire Drawing Machines

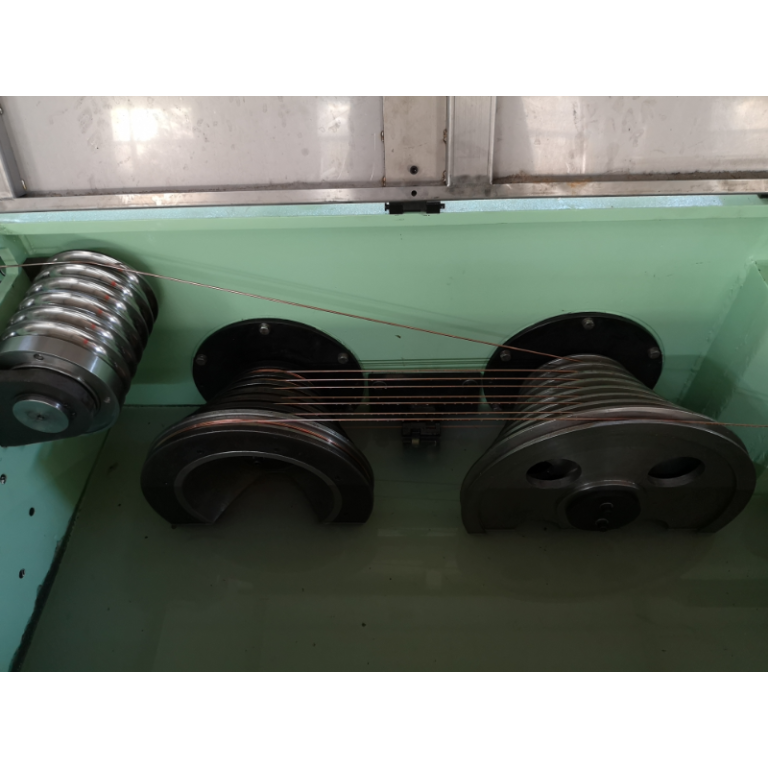

Automatic Aluminum Wire Drawing Machine is essential tools in the manufacturing industry, used to produce high-quality aluminum wires of various sizes and diameters. These machines are designed to efficiently pull aluminum rods through a series of dies to reduce their diameter and improve their surface finish. To ensure the smooth operation and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some important maintenance tips for automatic aluminum wire drawing machines.

One of the most important maintenance tasks for automatic aluminum wire drawing machines is regular cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. It is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help reduce friction and wear, prolonging the machine’s lifespan.

Another crucial maintenance tip for automatic aluminum wire drawing machines is inspecting and replacing worn or damaged parts. Regularly check the machine’s dies, rollers, and bearings for signs of wear and tear. If any parts are damaged or worn out, they should be replaced immediately to prevent further damage to the machine and ensure optimal performance. It is also important to check the machine’s electrical components, such as motors and sensors, for any signs of malfunction and repair or replace them as needed.

Proper tension control is essential for the efficient operation of automatic Aluminum Alloy Wire Drawing Machine. Improper tension can lead to wire breakage, poor wire quality, and machine damage. Regularly check and adjust the tension settings on the machine to ensure that the wire is being pulled through the dies at the correct speed and with the right amount of force. Additionally, regularly inspect the wire guides and straighteners to ensure that the wire is being fed smoothly through the machine without any obstructions.

Regularly monitoring the machine’s performance is another important maintenance tip for automatic aluminum wire drawing machines. Keep track of the machine’s production output, wire quality, and any unusual noises or vibrations. If you notice any issues, address them promptly to prevent further damage to the machine. It is also a good idea to keep a maintenance log to record any maintenance tasks performed on the machine and track its performance over time.

In conclusion, regular maintenance is essential for the smooth operation and longevity of automatic aluminum wire drawing machines. By following these maintenance tips, you can ensure that your machine continues to produce high-quality aluminum wires efficiently and effectively. Remember to clean the machine regularly, inspect and replace worn parts, maintain proper tension control, and monitor the machine’s performance. With proper maintenance, your automatic aluminum wire drawing machine will continue to be a valuable asset in your manufacturing process.

How Automatic Aluminum Wire Drawing Machines Improve Efficiency in Manufacturing

Automatic Aluminum Fine Wire Drawing Machine has revolutionized the manufacturing industry by significantly improving efficiency and productivity. These machines are designed to automate the process of drawing aluminum wire, which involves pulling a metal rod through a series of dies to reduce its diameter and increase its length. By automating this process, manufacturers can produce high-quality aluminum wire at a faster rate and with greater precision.

One of the key benefits of automatic aluminum wire drawing machines is their ability to increase production speed. These machines are capable of drawing aluminum wire at a much faster rate than manual methods, allowing manufacturers to meet the demands of a rapidly growing market. By automating the drawing process, manufacturers can produce more wire in less time, leading to increased output and higher profits.

In addition to increasing production speed, automatic aluminum wire drawing machines also improve the quality of the wire produced. These machines are equipped with advanced technology that ensures the wire is drawn to precise specifications, resulting in a consistent diameter and smooth surface finish. This level of precision is difficult to achieve with manual methods, where human error can lead to variations in wire diameter and surface imperfections.

Furthermore, automatic aluminum wire drawing machines are highly efficient in terms of energy consumption. These machines are designed to operate with minimal energy input, reducing the overall cost of production. By using less energy, manufacturers can save money on utility bills and reduce their carbon footprint, making automatic aluminum wire drawing machines a sustainable choice for environmentally conscious companies.

Another advantage of automatic aluminum wire drawing machines is their versatility. These machines can be easily adjusted to accommodate different wire diameters and materials, making them suitable for a wide range of applications. Whether manufacturers need to produce thin aluminum wire for electrical wiring or thick wire for industrial applications, automatic drawing machines can meet their needs with ease.

Moreover, automatic aluminum wire drawing machines require minimal maintenance and upkeep, making them a cost-effective investment for manufacturers. These machines are built to withstand heavy use and are designed to last for many years, reducing the need for frequent repairs or replacements. By investing in automatic drawing machines, manufacturers can save money on maintenance costs and ensure a reliable production process.

Overall, automatic aluminum wire drawing machines offer numerous benefits for manufacturers looking to improve efficiency and productivity. From increased production speed and improved quality to energy efficiency and versatility, these machines are a valuable asset for any manufacturing operation. By automating the wire drawing process, manufacturers can streamline their production process, reduce costs, and stay competitive in a fast-paced market. With their advanced technology and reliable performance, automatic aluminum wire drawing machines are a smart choice for manufacturers looking to enhance their operations and achieve greater success.