Table of Contents

Maintenance Tips for Copper Rod Breakdown Machines

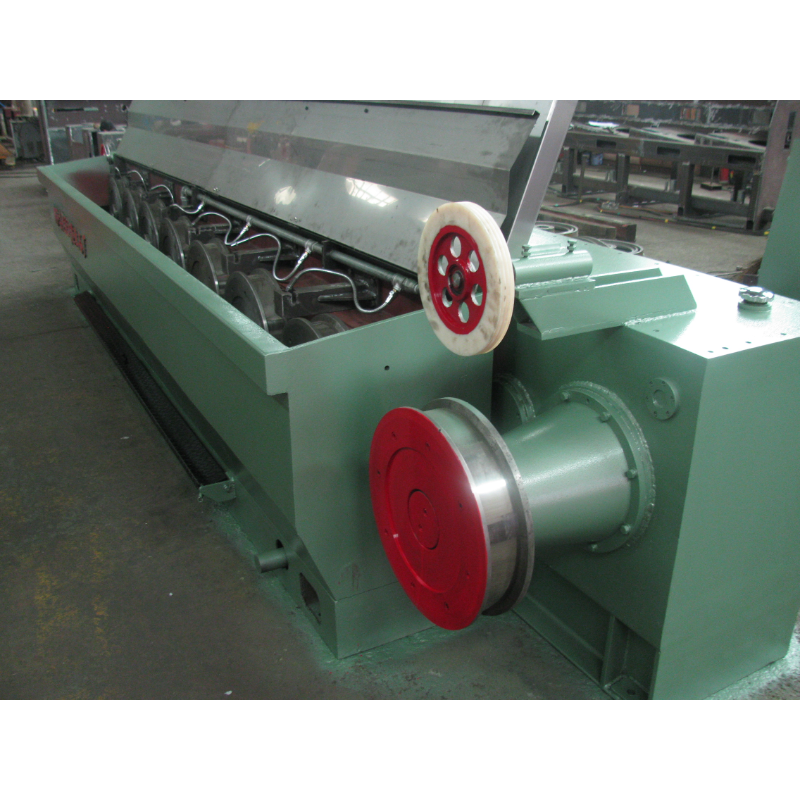

Copper Rod Casting and Making Machine is essential equipment in the wire and cable industry, used to reduce the diameter of copper rods to produce various sizes of copper wire. These machines are complex pieces of machinery that require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some maintenance tips for copper rod breakdown machines to help you keep your equipment running smoothly.

One of the most important maintenance tasks for copper rod breakdown machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. It is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant can help reduce friction and prevent premature wear.

Another crucial maintenance task for copper rod breakdown machines is inspecting and replacing worn or damaged parts. Over time, the components of the machine can wear out due to constant use, leading to decreased performance and potential breakdowns. It is essential to inspect the machine regularly for signs of wear and tear, such as loose or damaged belts, worn bearings, or cracked components. Replacing these parts promptly can help prevent more significant issues and prolong the machine’s lifespan.

In addition to regular cleaning and inspection, it is essential to calibrate the machine regularly to ensure accurate wire diameter and quality. Improper calibration can lead to variations in wire diameter, affecting the quality of the final product. It is crucial to follow the manufacturer’s guidelines for calibration and make any necessary adjustments to maintain consistent performance.

Furthermore, maintaining proper tension on the wire during the drawing process is essential for the machine’s operation. Incorrect tension can lead to wire breakage, uneven wire diameter, and other quality issues. It is crucial to monitor and adjust the tension settings regularly to ensure smooth operation and high-quality wire production.

Proper electrical maintenance is also crucial for Copper Fine Wire Drawing Machine With Annealer. Electrical components such as motors, controllers, and sensors play a vital role in the machine’s operation and must be inspected regularly for signs of wear or damage. It is essential to check the electrical connections, replace worn cables, and test the machine’s electrical systems periodically to prevent malfunctions and breakdowns.

In conclusion, regular maintenance is essential for keeping copper rod breakdown machines in optimal condition and ensuring high-quality wire production. By following these maintenance tips, you can prolong the lifespan of your equipment, reduce downtime, and improve overall efficiency. Remember to clean the machine regularly, inspect and replace worn parts, calibrate the machine, maintain proper tension, and perform electrical maintenance to keep your copper rod breakdown machine running smoothly. By taking care of your equipment, you can maximize its performance and productivity for years to come.

Advantages of Using Copper Rod Breakdown Machines in Wire Production

Copper rod breakdown machines play a crucial role in the wire production industry. These machines are designed to reduce the diameter of copper rods to the desired size, making them suitable for further processing into wires. There are several advantages to using copper rod breakdown machines in wire production.

One of the main advantages of using Copper Wire Drawing Machine for Rod Breakdown Machine is their efficiency. These machines are capable of processing large quantities of copper rods in a relatively short amount of time, making them ideal for high-volume production environments. This efficiency helps to increase overall productivity and reduce production costs, making copper rod breakdown machines a cost-effective solution for wire manufacturers.

In addition to their efficiency, copper rod breakdown machines also offer a high level of precision. These machines are able to accurately reduce the diameter of copper rods to the desired size, ensuring that the resulting wires meet the required specifications. This precision is essential for producing high-quality wires that meet industry standards and customer expectations.

Another advantage of using copper rod breakdown machines is their versatility. These machines are capable of processing a wide range of copper rod sizes, allowing manufacturers to produce wires of various diameters. This versatility makes copper rod breakdown machines suitable for a variety of applications, from small-scale wire production to large-scale industrial manufacturing.

Furthermore, copper rod breakdown machines are easy to operate and maintain. These machines are designed with user-friendly controls and are equipped with features that make them easy to set up and adjust. Additionally, copper rod breakdown machines are built to withstand the rigors of continuous operation, requiring minimal maintenance to keep them running smoothly.

In terms of safety, copper rod breakdown machines are equipped with safety features that help to protect operators and prevent accidents. These machines are designed with safety guards and emergency stop buttons to ensure the safety of personnel working with them. Additionally, copper rod breakdown machines are built with durable materials that help to prevent malfunctions and reduce the risk of injury.

Overall, the advantages of using copper rod breakdown machines in wire production are clear. These machines offer efficiency, precision, versatility, ease of operation, and safety, making them an essential tool for wire manufacturers. By investing in copper rod breakdown machines, manufacturers can increase productivity, reduce costs, and produce high-quality wires that meet industry standards.