Understand the Benefits of Using Copper Wire Drawing Machine for Manufacturing Processes

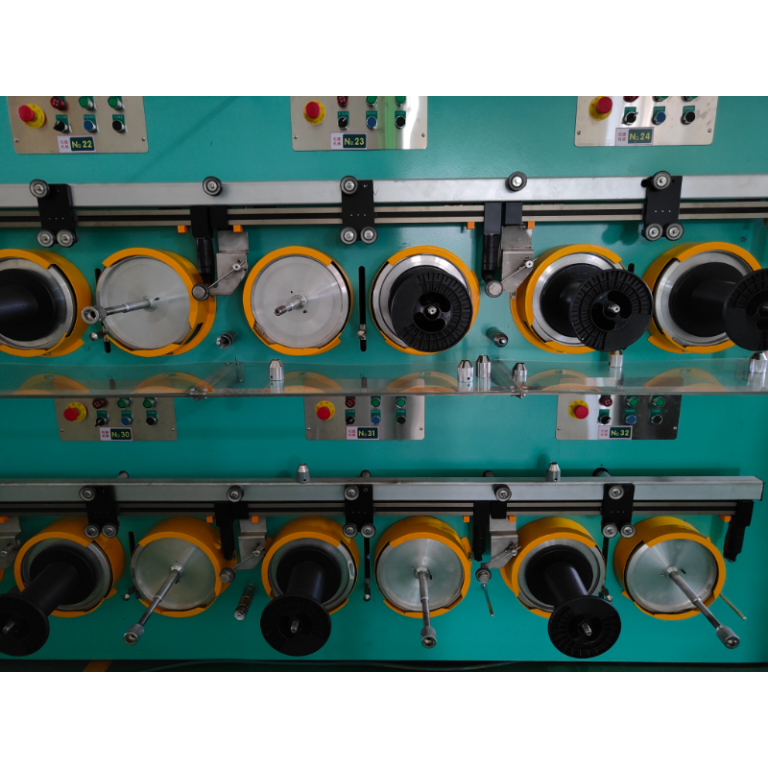

Copper wire drawing machines play a crucial role in the manufacturing industry, particularly in the production of copper wires. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its quality. There are several benefits to using copper wire drawing machines in manufacturing processes, which we will explore in this article.

One of the primary advantages of using Copper Fine Wire Drawing Machine With Annealer is the ability to produce wires of consistent diameter and quality. By passing the wire through a series of dies, the machine can control the diameter of the wire with precision, ensuring that each wire produced meets the required specifications. This level of consistency is essential in industries where the quality of the final product is paramount.

Another benefit of using copper wire drawing machines is the ability to increase the strength and conductivity of the wire. As the wire is drawn through the dies, its grain structure is refined, resulting in a stronger and more conductive material. This is particularly important in industries such as electronics and telecommunications, where the performance of the wire is critical to the overall functionality of the product.

In addition to improving the quality of the wire, copper wire drawing machines also offer increased efficiency in the manufacturing process. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to reduce production costs and lead times, making the manufacturing process more efficient and cost-effective.

Furthermore, copper wire drawing machines are versatile and can be used to produce wires of various diameters and lengths. This flexibility allows manufacturers to tailor their production to meet the specific requirements of their customers, ensuring that they can deliver a high-quality product that meets their needs. Whether producing thin wires for electronics or thick wires for construction, copper wire drawing machines can handle a wide range of wire sizes and types.

Additionally, using copper wire drawing machines can help to reduce waste in the manufacturing process. By drawing the wire to the desired diameter in a single pass, manufacturers can minimize the amount of material that is wasted during production. This not only helps to reduce costs but also makes the manufacturing process more environmentally friendly.

In conclusion, copper wire drawing machines offer a range of benefits for manufacturers in various industries. From improving the quality and consistency of the wire to increasing efficiency and reducing waste, these machines play a crucial role in the manufacturing process. By investing in copper wire drawing machines, manufacturers can enhance their production capabilities and deliver high-quality products to their customers.