Table of Contents

How to Choose the Right Copper Wire Drawing Making Machine for Your Business

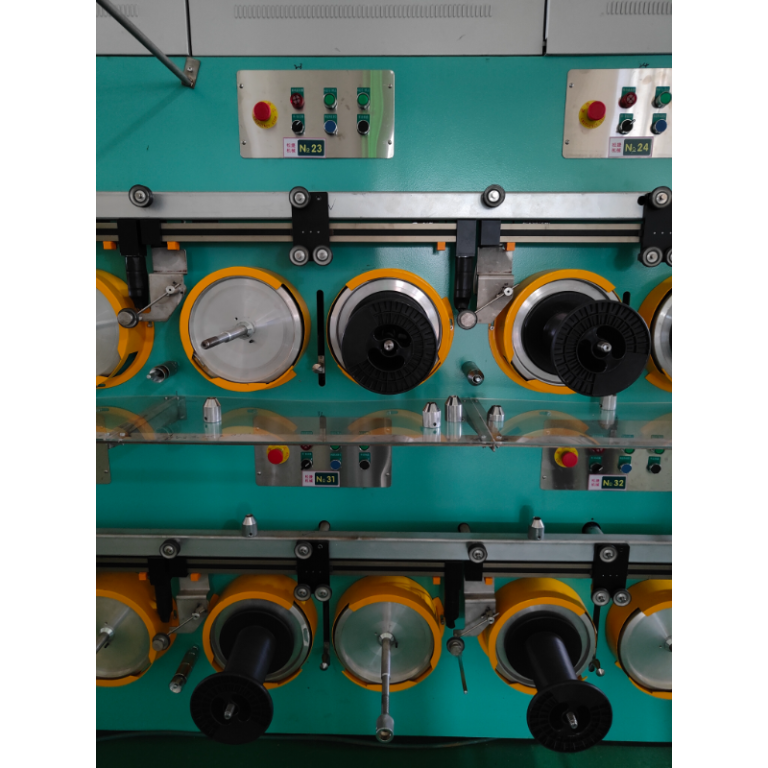

Copper wire drawing making machines are essential equipment for businesses involved in the production of copper wires. These machines are used to draw copper rods through a series of dies to reduce their diameter and produce wires of various sizes. Choosing the right Copper Wire Drawing Machine is crucial for ensuring the efficiency and quality of your production process. There are several factors to consider when selecting a machine that meets your business needs.

One of the first things to consider when choosing a copper wire drawing making machine is the production capacity. The production capacity of a machine is determined by the number of wires it can produce in a given time period. It is important to assess your business’s production requirements and choose a machine that can meet your output needs. Selecting a machine with a higher production capacity than what you currently need can help future-proof your business and accommodate potential growth.

Another important factor to consider is the wire diameter range that the machine can handle. Different machines are designed to draw wires of specific diameters, so it is essential to choose a machine that can produce the wire sizes required for your business. Consider the range of wire diameters you will be working with and select a machine that can accommodate those sizes.

The quality of the finished wire is also a critical consideration when choosing a Copper Fine Wire Drawing Machine With Annealer. Look for machines that are known for producing high-quality wires with consistent diameter and surface finish. A machine that can produce wires with minimal defects and imperfections will help improve the overall quality of your products and reduce waste.

Additionally, consider the level of automation and control features offered by the machine. Automated machines with advanced control systems can help streamline the production process, improve efficiency, and reduce the risk of human error. Look for machines with user-friendly interfaces and intuitive controls that make operation easy for your staff.

When selecting a copper wire drawing making machine, it is also important to consider the overall cost of ownership. In addition to the initial purchase price, factor in ongoing maintenance costs, energy consumption, and any additional expenses such as die replacements. Choose a machine that offers a good balance between upfront costs and long-term operating expenses to ensure a good return on investment.

Finally, consider the reputation and reliability of the manufacturer when choosing a copper wire drawing making machine. Look for manufacturers with a proven track record of producing high-quality machines and providing excellent customer support. A reputable manufacturer will stand behind their products and offer assistance with installation, training, and ongoing maintenance.

In conclusion, choosing the right copper wire drawing making machine is essential for the success of your business. Consider factors such as production capacity, wire diameter range, quality of finished wire, automation features, cost of ownership, and manufacturer reputation when making your decision. By selecting a machine that meets your business needs and requirements, you can ensure efficient production processes and high-quality products.

Benefits of Using Copper Wire Drawing Making Machines

Copper wire drawing making machines are essential tools in the manufacturing industry for producing high-quality copper wires. These machines are designed to draw copper rods through a series of dies to reduce their diameter and improve their mechanical properties. There are several benefits to using copper wire drawing making machines, including increased productivity, improved wire quality, and cost savings.

One of the primary benefits of using Copper Multiwire Drawing Machine is increased productivity. These machines are capable of drawing copper wires at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help companies meet tight production deadlines and fulfill customer orders quickly and efficiently. Additionally, the automated nature of these machines reduces the need for manual labor, further increasing productivity and reducing the risk of human error.

Another benefit of using copper wire drawing making machines is improved wire quality. As copper rods are drawn through the dies, they undergo a process of cold working that refines the grain structure of the metal and improves its mechanical properties. This results in copper wires that are stronger, more ductile, and have a smoother surface finish. Improved wire quality can lead to fewer defects and failures in the final product, reducing the likelihood of costly rework or product recalls.

In addition to increased productivity and improved wire quality, using copper wire drawing making machines can also lead to cost savings for manufacturers. By producing copper wires in-house rather than outsourcing production to a third party, companies can reduce lead times, transportation costs, and the risk of supply chain disruptions. Furthermore, the high efficiency of these machines means that less raw material is wasted during the drawing process, resulting in lower material costs and higher overall profitability.

Overall, the benefits of using copper wire drawing making machines are clear. These machines offer increased productivity, improved wire quality, and cost savings for manufacturers in the copper wire industry. By investing in these machines, companies can streamline their production processes, enhance the quality of their products, and ultimately improve their bottom line.

In conclusion, copper wire drawing making machines are essential tools for manufacturers looking to produce high-quality copper wires efficiently and cost-effectively. These machines offer a range of benefits, including increased productivity, improved wire quality, and cost savings. By investing in copper wire drawing making machines, companies can enhance their competitiveness in the market and meet the growing demand for high-quality copper wires.