Table of Contents

Maintenance Tips for D Type Medium Speed On Line Drawing Enameling Machine

Maintaining a D Type Medium Speed On Line Drawing Enameling Machine is crucial for ensuring its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also helps in maintaining the quality of the enameled products. In this article, we will discuss some essential maintenance tips for the D Type Medium Speed On Line Drawing Enameling Machine.

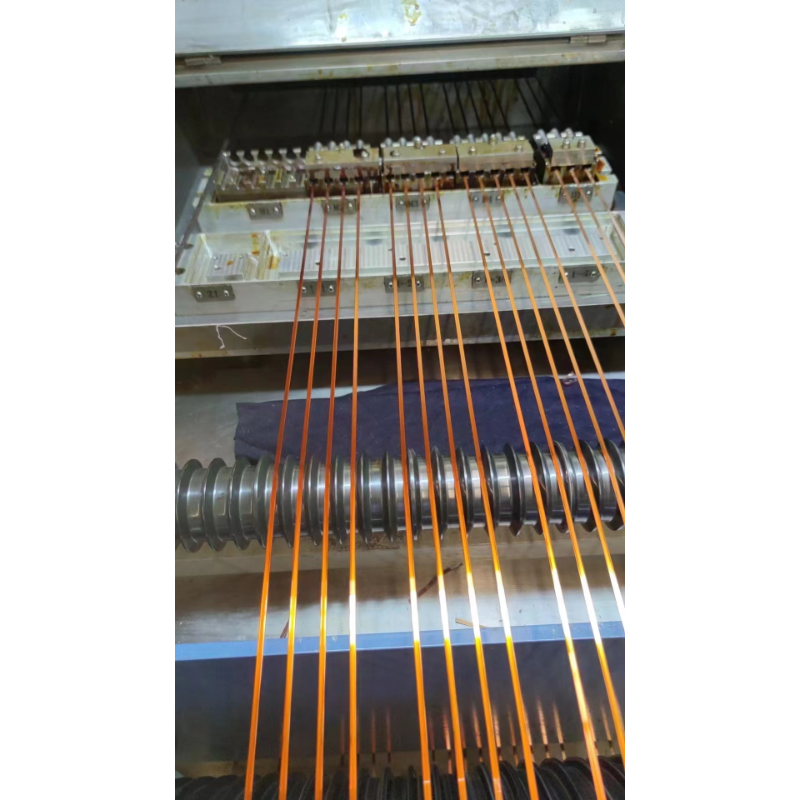

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking the rollers, guides, and other moving parts for any signs of damage or excessive wear. Any worn-out or damaged parts should be replaced immediately to prevent further damage to the machine.

In addition to inspecting the machine for physical damage, it is also important to regularly lubricate the moving parts of the machine. Proper lubrication helps in reducing friction and wear on the moving parts, thereby extending the life of the machine. It is important to use the recommended lubricants and to follow the manufacturer’s guidelines for lubrication intervals.

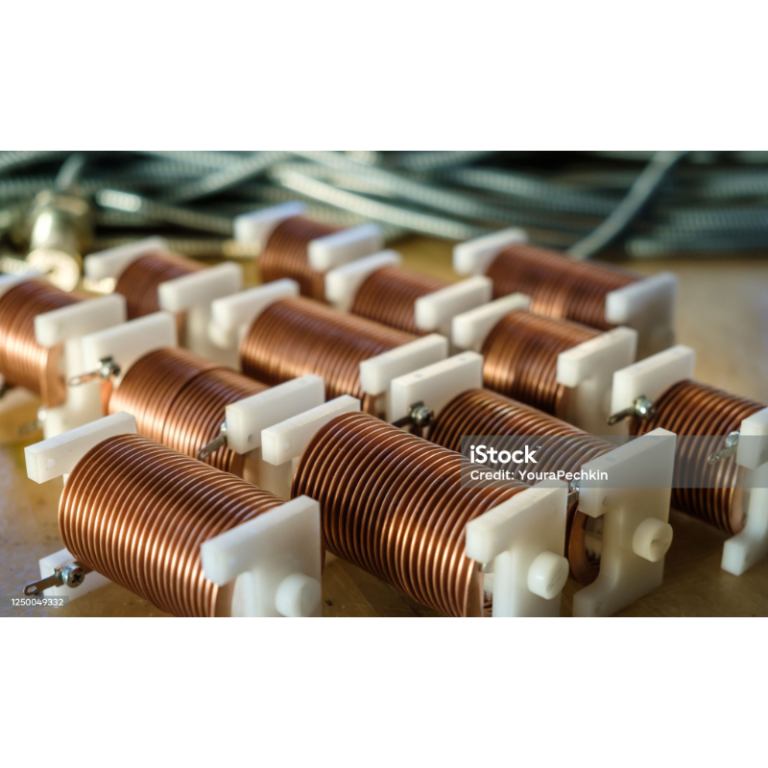

Another important aspect of maintaining the Wire Enameling Plant is to regularly clean the machine and its components. This includes removing any built-up enamel or debris from the rollers, guides, and other components. Regular cleaning not only helps in preventing damage to the machine but also ensures that the enameled products are of high quality.

Furthermore, it is important to regularly check the tension of the machine’s drive belts. Proper tension is crucial for the smooth operation of the machine, and loose or worn-out belts should be replaced immediately. Additionally, it is important to check the alignment of the machine’s components to ensure that they are properly aligned for optimal performance.

Regularly inspecting the electrical components of the machine is also crucial for its maintenance. This includes checking the wiring, switches, and other electrical components for any signs of damage or wear. Any damaged electrical components should be replaced immediately to prevent electrical hazards and machine malfunctions.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the D Type Medium Speed On Line Drawing Enameling Machine. This includes scheduling regular maintenance tasks such as lubrication, cleaning, and inspections. Following the recommended maintenance schedule helps in preventing unexpected breakdowns and ensures that the machine operates at its best.

In conclusion, maintaining a D Type Medium Speed On Line Drawing Enameling Machine is essential for its longevity and optimal performance. Regular inspection, lubrication, cleaning, and checking of the machine’s components are crucial for its maintenance. Following the manufacturer’s recommended maintenance schedule is also important for preventing unexpected breakdowns and ensuring the machine operates at its best. By following these maintenance tips, you can ensure that your D Type Medium Speed On Line Drawing Enameling Machine continues to produce high-quality enameled products for years to come.

How to Choose the Right D Type Medium Speed On Line Drawing Enameling Machine for Your Business

In the world of industrial manufacturing, choosing the right equipment for your business is crucial to ensuring efficiency, productivity, and quality. When it comes to enameling processes, the D Type Medium Speed On Line Drawing Enameling Machine is a popular choice for many businesses. This article will provide an overview of the key factors to consider when choosing the right D Type Medium Speed On Line Drawing Enameling Machine for your business.

First and foremost, it is important to consider the specific requirements of your enameling process. Different businesses have different production volumes, material specifications, and quality standards. Therefore, it is essential to assess your specific needs and ensure that the D Type Medium Speed On Line Drawing Enameling Coating Machine you choose is capable of meeting those requirements. This may involve consulting with an expert in enameling technology to determine the most suitable machine for your business.

Another important factor to consider is the overall quality and reliability of the machine. Enameling processes can be complex and demanding, and it is crucial to invest in a machine that is built to last and can consistently deliver high-quality results. Look for a machine that is manufactured by a reputable company with a proven track record in the industry. Additionally, consider the availability of technical support and spare parts, as this can significantly impact the long-term performance and maintenance of the machine.

In addition to quality and reliability, it is also important to consider the overall efficiency and productivity of the machine. Look for features such as automatic temperature control, variable speed settings, and user-friendly interfaces that can help streamline the enameling process and minimize downtime. A machine that is designed for easy maintenance and cleaning can also contribute to overall efficiency and productivity in the long run.

Furthermore, consider the space and layout of your production facility when choosing a D Type Medium Speed On Line Drawing Enameling Machine. Some machines may have specific space requirements or installation considerations that need to be taken into account. It is important to ensure that the machine can be seamlessly integrated into your existing production line without causing disruptions or inefficiencies.

Finally, it is important to consider the overall cost and return on investment of the machine. While it may be tempting to opt for the cheapest option, it is important to weigh the initial cost against the long-term benefits and performance of the machine. Consider factors such as energy efficiency, maintenance costs, and potential for future upgrades or expansions. Ultimately, investing in a high-quality D Type Medium Speed On Line Drawing Enameling Machine that is capable of meeting your specific requirements can result in significant cost savings and improved production capabilities in the long run.

In conclusion, choosing the right D Type Medium Speed On Line Drawing Enameling Machine for your business involves careful consideration of your specific requirements, as well as the overall quality, reliability, efficiency, and cost of the machine. By taking the time to assess these factors and consult with industry experts, you can make an informed decision that will benefit your business in the long run.

Benefits of Using D Type Medium Speed On Line Drawing Enameling Machine

Enameling is a process that involves applying a thin layer of glass to a metal surface, creating a durable and attractive finish. One of the most efficient and effective ways to apply enamel to metal is through the use of a D Type Medium Speed On Line Drawing Enameling Machine. This type of machine offers a range of benefits that make it an ideal choice for manufacturers and businesses looking to streamline their enameling process.

One of the key benefits of using a D Type Medium Speed On Line Drawing Enameling Machine is its ability to produce high-quality enamel finishes with precision and consistency. The machine is designed to apply enamel in a controlled and uniform manner, ensuring that the finished product meets the highest standards of quality. This level of precision is essential for businesses that require consistent and flawless enamel finishes on their products.

In addition to producing high-quality finishes, the D Type Medium Speed On Line Drawing Enameling Machine is also known for its efficiency and speed. The machine is capable of applying enamel to metal surfaces at a medium speed, allowing for a high level of productivity without sacrificing quality. This makes it an ideal choice for businesses that need to produce large quantities of enameled products in a short amount of time.

Another benefit of using a D Type Medium Speed On Line Drawing Enameling Machine is its versatility. The machine is capable of applying enamel to a wide range of metal surfaces, including steel, aluminum, and copper. This versatility makes it a valuable asset for businesses that work with different types of metals and need a single machine that can handle all of their enameling needs.

Furthermore, the D Type Medium Speed On Line Drawing Enameling Machine is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with intuitive controls and settings that allow operators to adjust the enamel application process to meet their specific needs. Additionally, the machine is built with durable and reliable components that require minimal maintenance, reducing downtime and ensuring consistent performance.

In conclusion, the D Type Medium Speed On Line Drawing Enameling Machine offers a range of benefits that make it an ideal choice for businesses looking to streamline their enameling process. From its ability to produce high-quality finishes with precision and consistency to its efficiency, speed, versatility, and user-friendly design, this machine is a valuable asset for any business that requires a reliable and efficient enameling solution. By investing in a D Type Medium Speed On Line Drawing Enameling Machine, businesses can improve their productivity, reduce costs, and ensure that their enameled products meet the highest standards of quality.