Step-By-Step Guide On How To Operate An Online Drawing Enameling Machine

An online drawing enameling machine is a sophisticated piece of equipment used in the manufacturing industry to apply a protective enamel coating to metal wires. This process helps to improve the durability and longevity of the wires, making them suitable for a wide range of applications. Operating an online drawing enameling machine requires precision and attention to detail to ensure that the enamel coating is applied evenly and effectively. In this article, we will provide a step-by-step guide on how to operate an online drawing enameling machine.

The first step in operating an online drawing Enameling Wire Production Line is to ensure that the machine is properly set up and calibrated. This includes checking that the wire feed mechanism is functioning correctly, the enamel coating is at the right temperature and viscosity, and the machine is clean and free from any debris. It is important to follow the manufacturer’s instructions for setting up the machine to ensure optimal performance.

Once the machine is set up, the next step is to feed the metal wire through the machine’s drawing dies. The drawing dies are used to reduce the diameter of the wire and ensure a smooth and uniform surface for the enamel coating to be applied. It is important to adjust the tension and speed of the wire feed to ensure that the wire is drawn through the machine at the correct rate.

After the wire has been drawn through the machine, the next step is to apply the enamel coating. The enamel coating is typically applied using a spray nozzle or a dipping process, depending on the type of machine being used. It is important to ensure that the enamel coating is applied evenly and consistently to achieve the desired level of protection for the wire.

Once the enamel coating has been applied, the wire is then passed through a curing oven to dry and harden the enamel. The curing process is essential to ensure that the enamel coating adheres properly to the wire and provides the necessary protection against corrosion and wear.

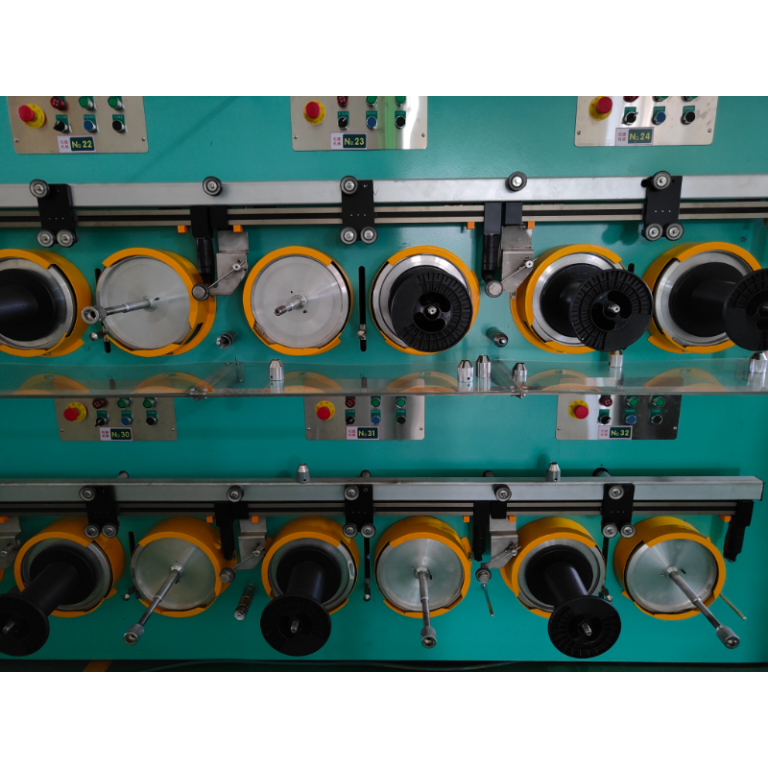

After the wire has been cured, it is then wound onto a spool or reel for storage or further processing. It is important to handle the wire carefully to avoid damaging the enamel coating and ensure that it remains intact during storage and transportation.

In conclusion, operating an online drawing enameling machine requires careful attention to detail and precision to ensure that the enamel coating is applied effectively and efficiently. By following the steps outlined in this guide, you can successfully operate an online drawing enameling machine and produce high-quality enamel-coated wires for a variety of applications.