Table of Contents

Explore The Benefits of Using Enameling Machine in China

Enameling machines have become an essential tool in the manufacturing industry in China. These machines offer a wide range of benefits that help companies improve their production processes and create high-quality products. In this article, we will explore the various advantages of using enameling machines in China.

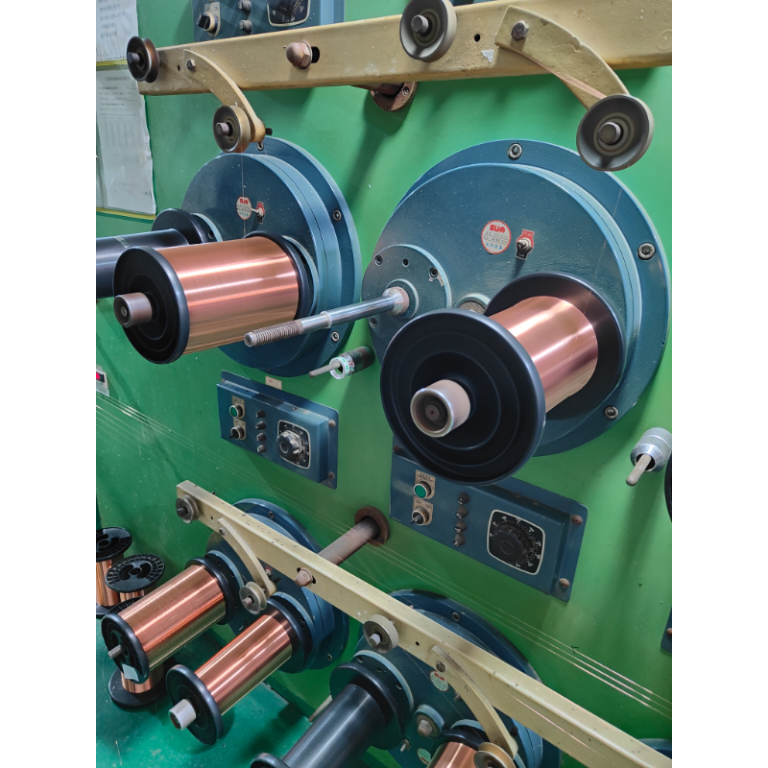

One of the primary benefits of using enameling machines is the efficiency they bring to the production process. These machines are designed to automate the enameling process, reducing the need for manual labor and increasing the speed at which products can be produced. This not only saves time but also allows companies to meet tight deadlines and increase their overall productivity.

In addition to efficiency, enameling machines also offer a high level of precision and consistency in the enameling process. These machines are programmed to apply the enamel coating evenly and accurately, ensuring that each product meets the desired quality standards. This level of precision is crucial in industries where quality control is paramount, such as the automotive or electronics industry.

Furthermore, Enameling Wire Production Line is versatile and can be used to enamel a wide range of products, from small components to large industrial parts. This flexibility allows companies to use the same machine for multiple applications, reducing the need for multiple machines and saving on costs. Additionally, enameling machines can be easily customized to meet specific production requirements, making them a valuable asset for companies with unique manufacturing needs.

Another significant benefit of using enameling machines in China is the cost savings they offer. By automating the enameling process, companies can reduce the amount of labor required, saving on labor costs. Additionally, the precision and efficiency of enameling machines help minimize material waste, further reducing production costs. Overall, using enameling machines can help companies improve their bottom line and remain competitive in the market.

Moreover, enameling machines are also environmentally friendly. These machines are designed to minimize the use of harmful chemicals and reduce emissions, making them a sustainable choice for companies looking to reduce their environmental impact. By using enameling machines, companies can improve their sustainability efforts and contribute to a cleaner, greener future.

In conclusion, enameling machines offer a wide range of benefits for companies in China. From increased efficiency and precision to cost savings and environmental sustainability, these machines are a valuable asset for any manufacturing operation. By investing in enameling machines, companies can improve their production processes, create high-quality products, and stay ahead of the competition.

How Enameling Machines are Revolutionizing the Chinese Manufacturing Industry

Enameling machines have become a crucial component in the Chinese manufacturing industry, revolutionizing the way products are produced and enhancing efficiency in the production process. These machines have significantly improved the quality and durability of products, making them more competitive in the global market.

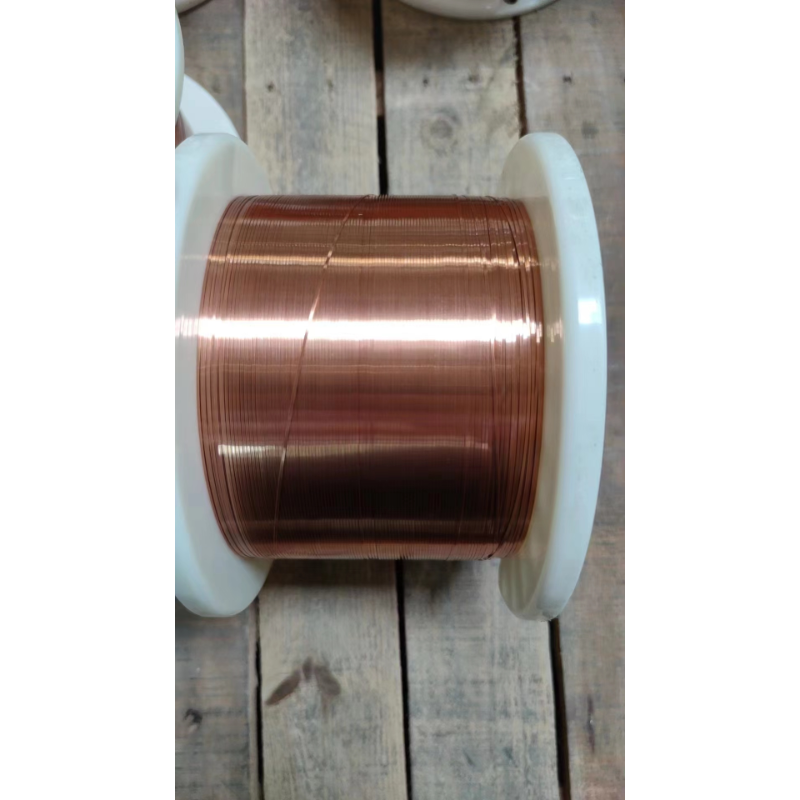

One of the key advantages of Enameling Machine for Copper Wire is their ability to apply a protective coating to metal surfaces, preventing corrosion and enhancing the aesthetic appeal of the finished product. This process involves applying a layer of enamel, a type of glass powder, to the metal surface and then heating it to high temperatures to fuse the enamel to the metal. The result is a smooth, durable finish that is resistant to scratches, stains, and other forms of damage.

Enameling machines are widely used in the production of a variety of products, including cookware, appliances, automotive parts, and industrial components. In the past, these products were often coated with paint or other types of finishes that were less durable and prone to chipping and peeling. With enameling machines, manufacturers can now produce products that are not only more durable but also more visually appealing, making them more attractive to consumers.

The use of enameling machines has also helped to streamline the production process, reducing the time and labor required to produce finished products. By automating the enameling process, manufacturers can produce products more quickly and efficiently, allowing them to meet the demands of a fast-paced market. This increased efficiency has also helped to reduce production costs, making products more affordable for consumers.

In addition to improving the quality and efficiency of production, enameling machines have also had a positive impact on the environment. The enameling process produces less waste and consumes fewer resources than traditional finishing methods, making it a more sustainable option for manufacturers. By reducing the amount of waste generated and conserving resources, enameling machines are helping to minimize the environmental impact of the manufacturing industry.

The use of enameling machines in China has grown significantly in recent years, as manufacturers seek to improve the quality and competitiveness of their products. Chinese manufacturers have embraced enameling technology as a way to differentiate their products in the global market and meet the growing demand for high-quality, durable goods. As a result, China has become a leading producer of enameled products, exporting a wide range of items to markets around the world.

The growth of the enameling machine industry in China has also created new opportunities for manufacturers and suppliers. As demand for enameled products continues to rise, there is a growing need for suppliers of enamel powders, coatings, and other materials used in the enameling process. This has led to the development of a thriving supply chain that supports the production of enameled products in China and beyond.

Overall, enameling machines have had a transformative impact on the Chinese manufacturing industry, improving the quality, efficiency, and sustainability of production processes. As manufacturers continue to embrace this technology, we can expect to see even greater advancements in the production of enameled products, further solidifying China’s position as a global leader in manufacturing.