Tips for Choosing the Right Enameling Wire Production Line for Your Business

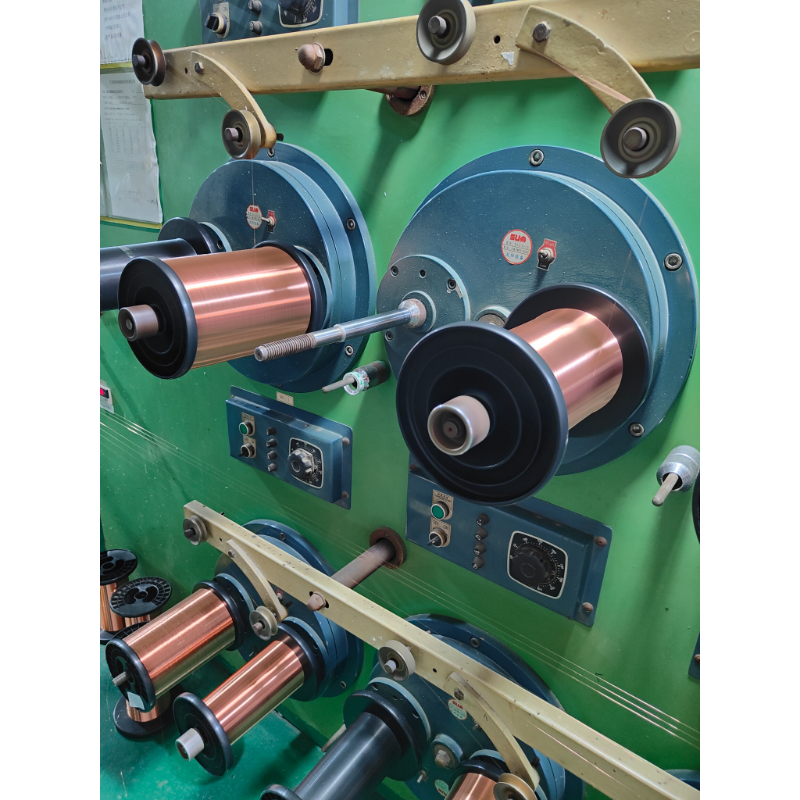

Enameling production lines are essential for businesses that specialize in creating enameled products such as cookware, jewelry, and decorative items. These production lines consist of various machines and equipment that are used to apply enamel coatings to metal surfaces, creating a durable and attractive finish. If you are in the market for an enameling production line, there are several factors to consider to ensure that you choose the right one for your business.

One of the first things to consider when choosing an Enameling Coating Machine is the size and capacity of the line. The size of the production line should be determined by the volume of products that you plan to produce. If you have a small business with limited production needs, a smaller production line may be sufficient. However, if you have a larger operation or plan to expand in the future, you may need a larger production line with higher capacity.

Another important factor to consider is the type of enameling process that the production line is designed for. There are several different enameling processes, including wet enamel, dry enamel, and powder coating. Each process has its own advantages and disadvantages, so it is important to choose a production line that is compatible with the type of enameling process that you plan to use.

In addition to the size and type of enameling process, you should also consider the quality and reliability of the production line. Look for a production line that is made by a reputable manufacturer with a track record of producing high-quality equipment. It is also important to consider the maintenance and support services that are available for the production line, as regular maintenance and servicing are essential for keeping the line running smoothly and efficiently.

When choosing an Wire Enameling Machine, it is also important to consider the cost of the equipment. Production lines can be a significant investment, so it is important to choose a line that fits within your budget. However, it is also important to consider the long-term costs of operating the production line, including maintenance, energy consumption, and labor costs. In some cases, it may be worth investing in a more expensive production line that is more efficient and reliable in the long run.

Finally, it is important to consider the flexibility and versatility of the production line. Look for a production line that can be easily adapted to different types of enameling processes and products. This will allow you to expand your product line and take on new projects without having to invest in a completely new production line.

In conclusion, choosing the right enameling production line for your business is a crucial decision that can have a significant impact on the success of your operation. By considering factors such as size, capacity, process compatibility, quality, cost, and flexibility, you can ensure that you choose a production line that meets your needs and helps you achieve your production goals. Take the time to research different options and consult with industry experts to find the best production line for your business.