Table of Contents

How to Choose the Right Enameling Machine for Your Business

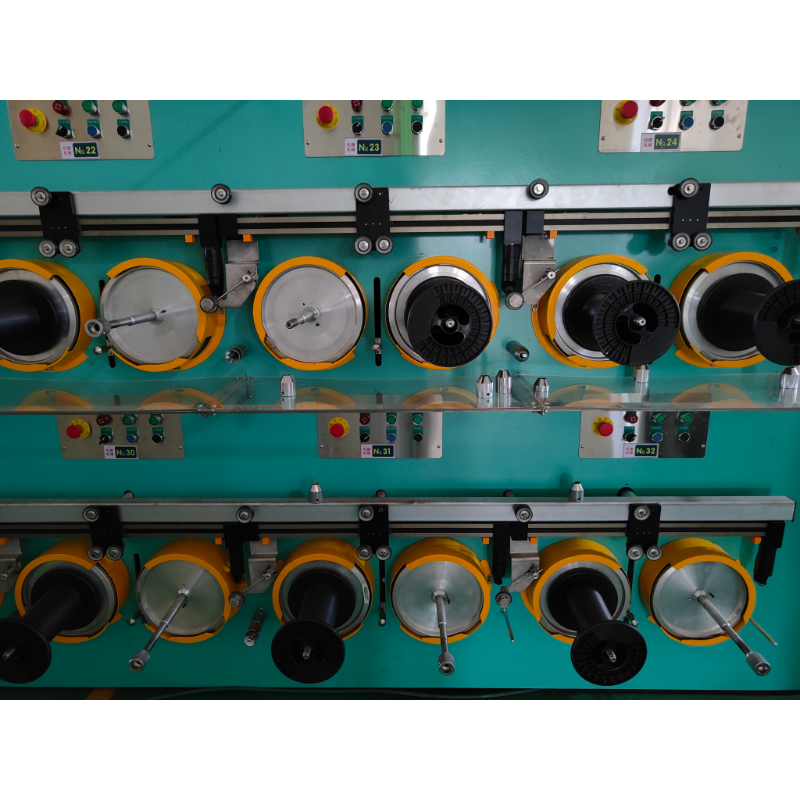

Enameling machines are essential tools for businesses in the jewelry, automotive, and household appliance industries. These machines are used to apply a protective and decorative coating of enamel to metal surfaces, providing a durable and attractive finish. If you are in the market for an enameling machine, there are several factors to consider to ensure you choose the right one for your business.

One of the first things to consider when looking for enameling machines for sale is the type of enamel you will be using. There are different types of enamels, such as liquid, powder, and electrostatic, each requiring a specific type of machine for application. It is important to choose a machine that is compatible with the type of enamel you will be using to ensure optimal results.

Another important factor to consider is the size and capacity of the Wire Enameling Plant. The size of the machine will depend on the volume of work you will be doing and the size of the items you will be enameling. It is important to choose a machine that can accommodate your production needs without being too large or too small for your workspace.

Additionally, it is important to consider the features and capabilities of the enameling machine. Some machines offer additional features such as temperature control, variable speed settings, and automatic cleaning functions. These features can help improve efficiency and quality in the enameling process, so it is important to choose a machine that offers the features you need for your business.

When looking for enameling machines for sale, it is also important to consider the reputation and reliability of the manufacturer. Choosing a machine from a reputable manufacturer can ensure that you are getting a high-quality product that will last for years to come. It is important to do your research and read reviews from other customers to ensure that you are choosing a reliable machine from a trusted manufacturer.

In addition to considering the type, size, features, and manufacturer of the Enameling Wire Production Line, it is also important to consider your budget. Enameling machines can vary widely in price, so it is important to set a budget and stick to it when looking for a machine. It is important to consider not only the upfront cost of the machine but also any additional costs such as maintenance, repairs, and supplies.

In conclusion, choosing the right enameling machine for your business is an important decision that requires careful consideration of several factors. By considering the type of enamel you will be using, the size and capacity of the machine, the features and capabilities, the reputation of the manufacturer, and your budget, you can ensure that you choose a machine that meets your production needs and provides high-quality results. With the right enameling machine, you can improve efficiency, quality, and productivity in your business.

Benefits of Investing in Enameling Machines For Sale

Enameling machines are a crucial piece of equipment for businesses in the enamel industry. These machines are used to apply a protective and decorative coating to various metal surfaces, providing a durable finish that is resistant to corrosion and wear. Investing in enameling machines for sale can offer a range of benefits for businesses looking to improve their production processes and enhance the quality of their products.

One of the key benefits of investing in Enameling Coating Machine for sale is the ability to increase production efficiency. Enameling machines are designed to apply coatings quickly and evenly, allowing businesses to complete large orders in a fraction of the time it would take using manual methods. This can help businesses meet tight deadlines and fulfill customer orders more efficiently, ultimately leading to increased profitability.

In addition to improving production efficiency, enameling machines can also help businesses improve the quality of their products. These machines are designed to apply coatings with precision and consistency, ensuring that each finished product meets the highest standards of quality. This can help businesses enhance their reputation for producing high-quality products and attract more customers to their brand.

Another benefit of investing in enameling machines for sale is the ability to reduce labor costs. By automating the enameling process, businesses can eliminate the need for manual labor and reduce the number of employees required to complete production tasks. This can lead to significant cost savings over time, allowing businesses to invest in other areas of their operations and grow their business more effectively.

Enameling machines for sale also offer businesses the flexibility to customize their products and create unique finishes that set them apart from their competitors. These machines can be programmed to apply coatings in a variety of colors and textures, allowing businesses to create custom finishes that meet the specific needs of their customers. This can help businesses attract new customers and expand their market reach, ultimately leading to increased sales and revenue.

Furthermore, investing in enameling machines for sale can help businesses reduce waste and improve sustainability. These machines are designed to apply coatings with minimal overspray and waste, helping businesses minimize their environmental impact and reduce their carbon footprint. By investing in sustainable production practices, businesses can attract environmentally conscious customers and enhance their reputation as a socially responsible brand.

Overall, investing in enameling machines for sale can offer a range of benefits for businesses in the enamel industry. From improving production efficiency and product quality to reducing labor costs and enhancing customization options, these machines can help businesses streamline their operations and grow their business more effectively. By investing in enameling machines, businesses can position themselves for long-term success and achieve their goals of producing high-quality products that meet the needs of their customers.