Table of Contents

Trends and Innovations in Enameling Production Line Technology in China

Enameling Wire Production Line in China have seen significant advancements in technology in recent years. With the growing demand for high-quality enameled products, manufacturers in China have been investing in innovative production line technology to improve efficiency and product quality.

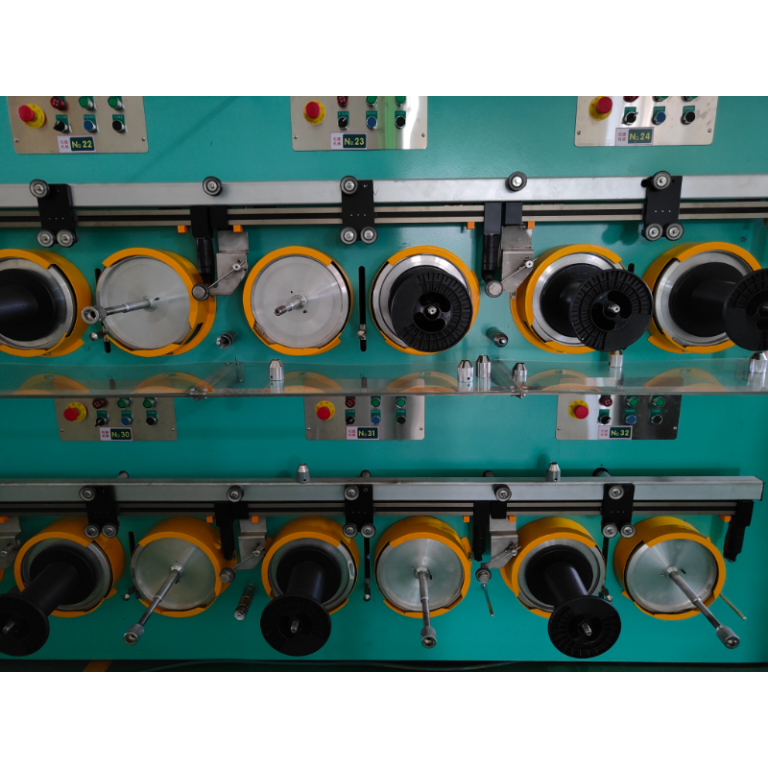

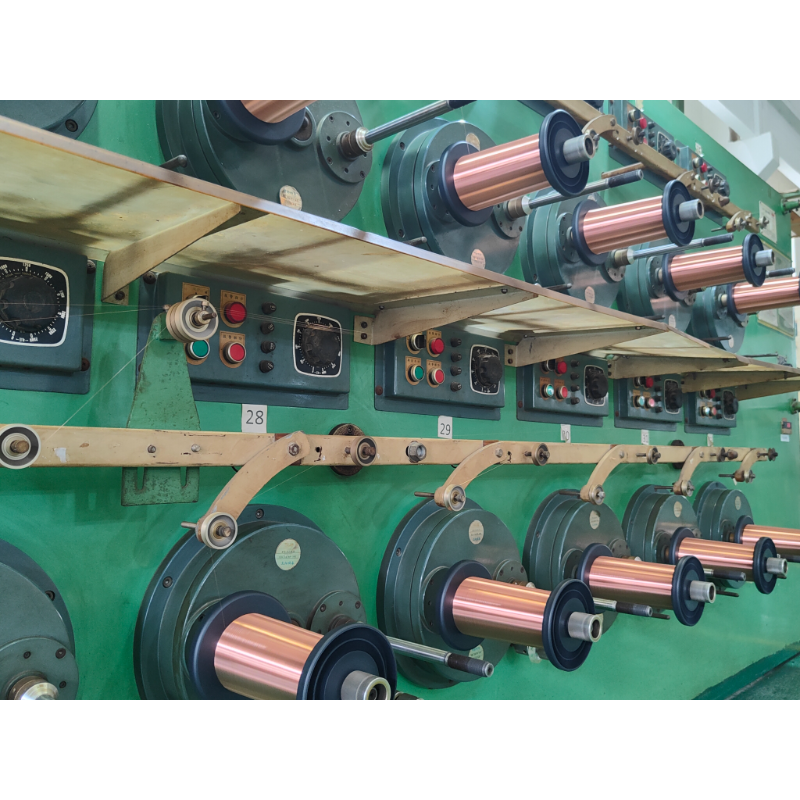

One of the key trends in enameling production line technology in China is the use of automation. Automation has revolutionized the enameling process by reducing human error and increasing production speed. Automated enameling production lines are equipped with sensors and robotics that can precisely control the application of enamel, resulting in a more uniform and consistent finish. This not only improves the quality of the final product but also reduces waste and production costs.

Another trend in enameling production line technology in China is the integration of digital monitoring and control systems. These systems allow manufacturers to monitor and adjust various parameters in real-time, such as temperature, speed, and thickness of the enamel coating. This level of control ensures that the enameling process is optimized for maximum efficiency and quality. Additionally, digital monitoring systems can provide valuable data for process optimization and predictive maintenance, helping manufacturers to improve overall production performance.

Innovations in enameling production line technology in China have also focused on sustainability and environmental impact. Manufacturers are increasingly adopting eco-friendly enamels and coatings that are free from harmful chemicals and reduce emissions. Enameling production lines are being designed with energy-efficient systems and waste management solutions to minimize environmental impact. By incorporating sustainable practices into their production processes, manufacturers in China are not only meeting regulatory requirements but also appealing to environmentally conscious consumers.

Furthermore, advancements in Enameling Machine technology in China have led to the development of customizable and flexible production lines. Manufacturers can now easily switch between different enamel colors, finishes, and thicknesses to meet the diverse needs of their customers. This flexibility allows for greater customization and personalization of enameled products, giving manufacturers a competitive edge in the market.

The adoption of Industry 4.0 principles in enameling production line technology is another significant trend in China. Industry 4.0 technologies, such as artificial intelligence, Internet of Things (IoT), and big data analytics, are being integrated into enameling production lines to improve efficiency, productivity, and quality. These technologies enable manufacturers to automate decision-making processes, optimize production schedules, and predict maintenance needs, leading to a more streamlined and efficient production process.

In conclusion, enameling production line technology in China is undergoing rapid advancements driven by automation, digital monitoring, sustainability, customization, and Industry 4.0 principles. These trends are reshaping the enameling industry in China, making production processes more efficient, sustainable, and flexible. As manufacturers continue to invest in innovative technologies, the future of enameling production lines in China looks promising, with a focus on quality, efficiency, and environmental responsibility.

Benefits of Investing in Enameling Production Line in China

Enameling production lines have become increasingly popular in China due to their efficiency and cost-effectiveness. Investing in an enameling production line in China can offer a wide range of benefits for businesses looking to expand their operations and increase their production capacity.

One of the key benefits of investing in an Enameling Coating Machine in China is the lower labor costs compared to many other countries. China has a large and skilled workforce that is able to handle the intricate processes involved in enameling production. This can result in significant cost savings for businesses looking to produce enameled products on a large scale.

In addition to lower labor costs, China also offers a wide range of raw materials at competitive prices. This can further reduce production costs and increase the profitability of businesses investing in enameling production lines in China. The availability of raw materials in China also ensures a steady supply chain, reducing the risk of production delays or shortages.

Furthermore, China has a well-developed infrastructure that supports the manufacturing industry. This includes modern transportation networks, reliable energy sources, and access to advanced technology. Investing in an enameling production line in China can benefit from this infrastructure, ensuring smooth operations and efficient production processes.

Another advantage of investing in an enameling production line in China is the access to a large market of consumers. China has a rapidly growing middle class with increasing purchasing power, creating a high demand for enameled products. By setting up production facilities in China, businesses can tap into this market and increase their sales and revenue.

Moreover, China has a favorable business environment with supportive government policies and incentives for foreign investors. This can make it easier for businesses to set up operations in China and navigate the regulatory landscape. The government also offers tax breaks and subsidies to encourage investment in the manufacturing sector, further enhancing the attractiveness of investing in an enameling production line in China.

Additionally, investing in an enameling production line in China can help businesses diversify their supply chain and reduce risks associated with overreliance on a single location. By spreading production across different countries, businesses can mitigate the impact of geopolitical events, natural disasters, or other disruptions that may affect production in one location.

In conclusion, investing in an enameling production line in China offers a wide range of benefits for businesses looking to expand their operations and increase their production capacity. From lower labor costs and access to raw materials to a large consumer market and supportive government policies, China provides a favorable environment for manufacturing investments. By taking advantage of these benefits, businesses can enhance their competitiveness and drive growth in the global market.