Benefits of Using Enameling Wire in Production Lines

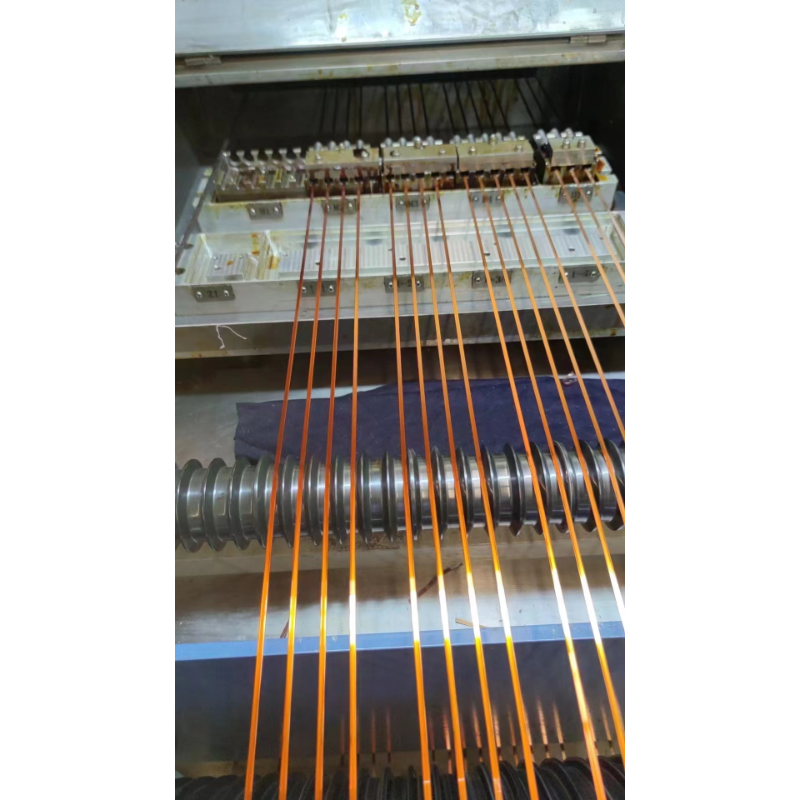

Enameling wire is a type of wire that is coated with a thin layer of insulation, typically made of enamel. This insulation provides protection against electrical currents and prevents short circuits. Enameling wire is commonly used in various industries, including electronics, automotive, and telecommunications. One of the key benefits of using enameling wire in production lines is its ability to improve the efficiency and reliability of electrical systems.

Enameling wire is known for its high electrical conductivity, which allows for the efficient transmission of electrical signals. This is particularly important in production lines where precision and accuracy are crucial. By using enameling wire, manufacturers can ensure that their electrical systems operate smoothly and reliably, reducing the risk of downtime and costly repairs.

Another benefit of enameling wire is its durability and resistance to wear and tear. The enamel coating provides a protective barrier that shields the wire from external elements, such as moisture, heat, and chemicals. This makes enameling wire ideal for use in harsh environments where traditional wire insulation may not be sufficient. By using enameling wire in production lines, manufacturers can increase the lifespan of their electrical systems and reduce maintenance costs.

In addition to its durability, enameling wire is also known for its flexibility and ease of use. The thin enamel coating allows for easy stripping and soldering, making it simple to work with in production lines. This flexibility is especially beneficial in industries where space is limited, as enameling wire can be easily routed and installed in tight spaces without sacrificing performance.

Furthermore, enameling wire is available in a wide range of sizes and colors, making it suitable for a variety of applications. Manufacturers can choose the appropriate gauge and color of enameling wire to meet their specific requirements, ensuring that their production lines operate efficiently and effectively. This versatility makes enameling wire a popular choice among manufacturers looking to optimize their electrical systems.

Overall, the benefits of using enameling wire in production lines are clear. From its high electrical conductivity and durability to its flexibility and versatility, enameling wire offers numerous advantages that can help manufacturers improve the efficiency and reliability of their electrical systems. By incorporating enameling wire into their production lines, manufacturers can ensure that their operations run smoothly and effectively, ultimately leading to increased productivity and profitability.