Table of Contents

Tips for Choosing the Right Enameling Wire Production Line Supplier in China

Enameling wire production lines are essential for manufacturing high-quality enameled wires used in various industries such as electronics, automotive, and telecommunications. If you are in the market for an Enameling Coating Machine, China is a popular destination due to its reputation for producing high-quality machinery at competitive prices. However, with so many suppliers to choose from, it can be overwhelming to find the right one for your specific needs. Here are some tips to help you choose the right enameling wire production line supplier in China.

First and foremost, it is crucial to do thorough research on potential suppliers. Look for suppliers with a solid reputation in the industry and a track record of delivering high-quality machinery. Reading customer reviews and testimonials can give you valuable insights into the supplier’s reliability and the quality of their products. Additionally, check if the supplier has the necessary certifications and accreditations to ensure that their machinery meets industry standards.

When choosing an enameling wire production line supplier in China, it is essential to consider the supplier’s experience and expertise in the industry. Look for suppliers with a proven track record of manufacturing enameling wire production lines and providing excellent customer service. An experienced supplier will be able to understand your specific requirements and provide you with customized solutions that meet your production needs.

Another important factor to consider when choosing an Enameling Machine for Aluminum Wire supplier in China is the quality of their machinery. Inspect the supplier’s production facilities and equipment to ensure that they use state-of-the-art technology and adhere to strict quality control standards. High-quality machinery will not only produce superior enameled wires but also have a longer lifespan, reducing maintenance costs in the long run.

Cost is also a crucial consideration when choosing an enameling wire production line supplier in China. While it is tempting to opt for the cheapest option, it is essential to balance cost with quality. Look for suppliers that offer competitive prices without compromising on the quality of their machinery. Consider factors such as warranty, after-sales support, and maintenance services when evaluating the overall cost of the machinery.

Communication is key when working with a supplier in China, especially when dealing with language and cultural differences. Choose a supplier that has a dedicated customer service team that can effectively communicate with you in your preferred language. Clear communication will help prevent misunderstandings and ensure that your requirements are met.

In conclusion, choosing the right enameling wire production line supplier in China requires careful consideration of various factors such as reputation, experience, quality, cost, and communication. By doing thorough research and evaluating potential suppliers based on these criteria, you can find a reliable partner that will provide you with high-quality machinery to meet your production needs. Remember to prioritize quality and reliability when making your decision, as investing in a reputable supplier will pay off in the long run.

Benefits of Using Enameling Wire Production Line in China Factory

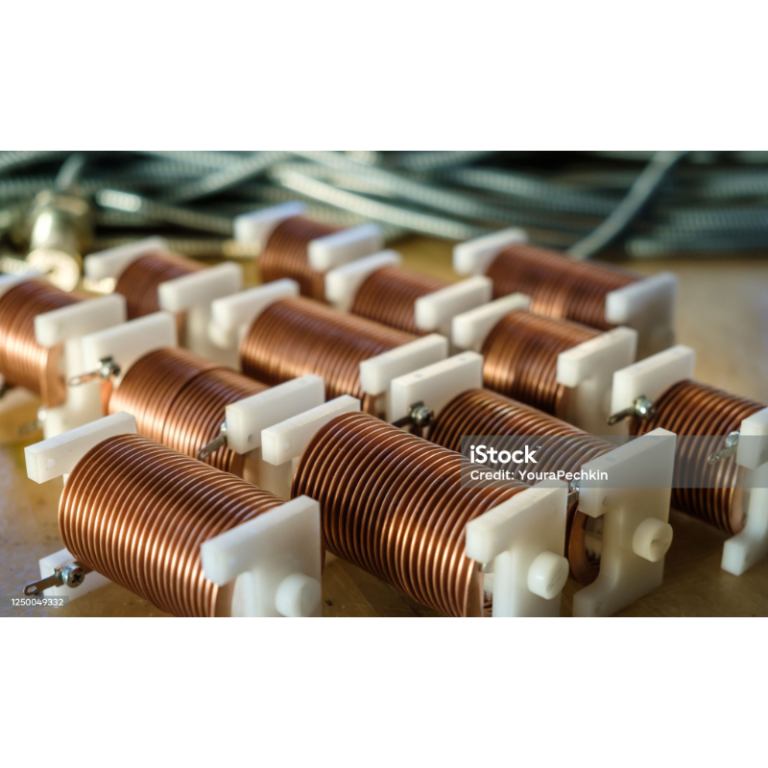

Enameling wire production lines are essential in the manufacturing process of various electrical components. These production lines are used to apply a thin layer of enamel insulation to copper or aluminum wire, which is crucial for ensuring the durability and performance of the wire in electrical applications. In China, there are numerous factories that specialize in the production of enameling wire, and many of them utilize advanced enameling wire production lines to meet the high demand for quality wire products.

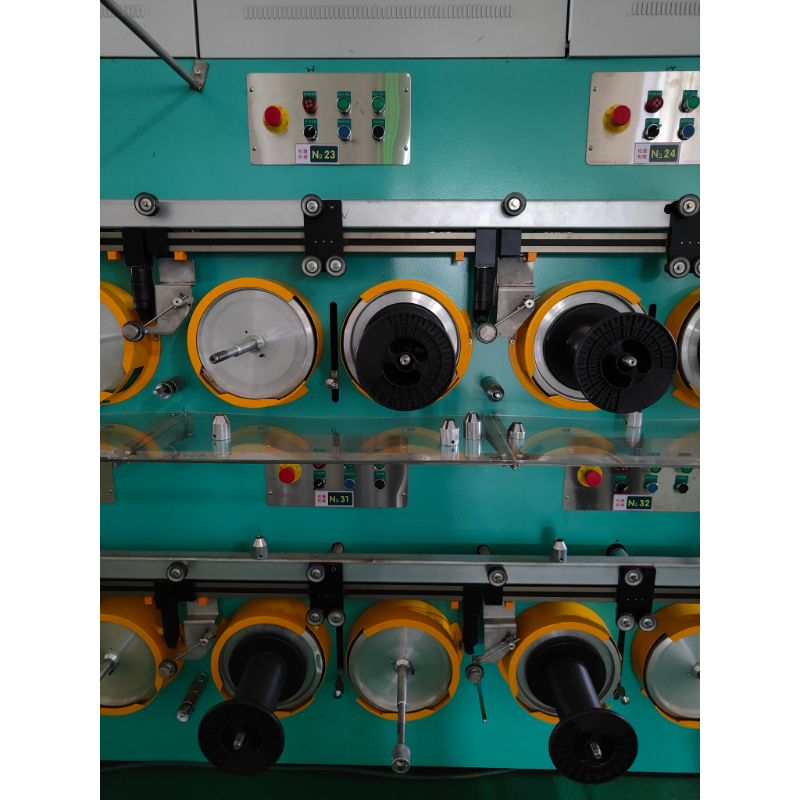

One of the key benefits of using an Enameling Machine for Copper Wire in a China factory is the efficiency and precision it offers in the wire coating process. These production lines are equipped with advanced technology and automation systems that allow for precise control over the application of enamel insulation on the wire. This results in a consistent and uniform coating that meets the required specifications for electrical conductivity and insulation. Additionally, the high-speed operation of these production lines enables manufacturers to produce large quantities of enameling wire in a short amount of time, which is essential for meeting tight production deadlines and fulfilling customer orders.

Another advantage of using an enameling wire production line in a China factory is the cost-effectiveness it provides. By automating the wire coating process, manufacturers can reduce labor costs and minimize material waste, resulting in overall cost savings. Additionally, the high efficiency of these production lines allows manufacturers to increase their production capacity and meet the growing demand for enameling wire products without significantly increasing their operational costs. This makes enameling wire production lines a cost-effective solution for manufacturers looking to improve their production processes and remain competitive in the market.

In addition to efficiency and cost-effectiveness, enameling wire production lines in China factories also offer superior quality control and product consistency. These production lines are equipped with quality inspection systems that monitor the coating process and ensure that the enamel insulation meets the required standards for thickness, adhesion, and uniformity. This helps manufacturers to produce high-quality enameling wire products that are reliable and durable, which is essential for ensuring the safety and performance of electrical systems and devices.

Furthermore, using an enameling wire production line in a China factory allows manufacturers to customize their wire products to meet specific requirements and specifications. These production lines can be programmed to apply different types of enamel insulation, such as polyester, polyurethane, or polyesterimide, depending on the intended application of the wire. This flexibility in customization enables manufacturers to produce a wide range of enameling wire products that cater to diverse industry needs, from automotive and electronics to telecommunications and appliances.

Overall, the benefits of using an enameling wire production line in a China factory are numerous and significant. From efficiency and cost-effectiveness to quality control and customization, these production lines offer manufacturers a competitive edge in the production of high-quality enameling wire products. By investing in advanced enameling wire production lines, manufacturers can improve their production processes, increase their production capacity, and meet the growing demand for quality wire products in the global market.