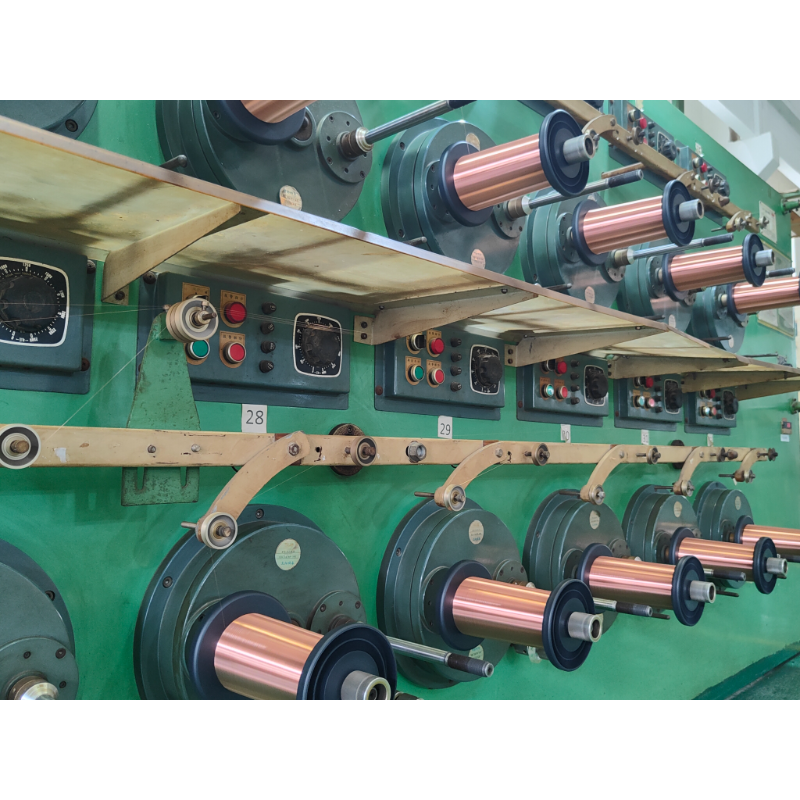

Maintenance Tips for Ensuring Longevity of Fine Wire Enameling Machine

Enameling machines are essential tools in the manufacturing industry, used for applying a protective coating of enamel to various metal products. These machines are intricate pieces of equipment that require regular maintenance to ensure their longevity and optimal performance. By following a few simple maintenance tips, you can keep your enameling machine running smoothly for years to come.

One of the most important maintenance tasks for enameling machines is regular cleaning. Over time, enamel residue can build up on the machine’s components, leading to decreased efficiency and potential damage. To prevent this buildup, it is essential to clean the machine thoroughly after each use. Use a soft brush or cloth to remove any excess enamel from the machine’s surfaces, paying particular attention to areas where enamel tends to accumulate, such as the nozzles and rollers.

In addition to regular cleaning, it is crucial to inspect the machine for any signs of wear or damage. Check the machine’s rollers, nozzles, and other components for any cracks, dents, or other issues that could affect its performance. If you notice any damage, it is essential to address it promptly to prevent further problems. Replace any worn or damaged parts as needed to keep the machine in optimal working condition.

Another important maintenance tip for Enameling Wire Production Line is to lubricate the machine’s moving parts regularly. Proper lubrication helps reduce friction and wear on the machine’s components, extending its lifespan and ensuring smooth operation. Use a high-quality lubricant recommended by the machine’s manufacturer and follow the manufacturer’s guidelines for lubrication frequency and application.

In addition to regular cleaning and lubrication, it is essential to calibrate the machine regularly to ensure accurate enamel application. Improper calibration can lead to uneven coating thickness and other issues that can affect the quality of the finished product. Follow the manufacturer’s guidelines for calibration and make any necessary adjustments to ensure the machine is operating correctly.

Finally, it is essential to store the enameling machine properly when not in use. Store the machine in a clean, dry environment away from dust, moisture, and other contaminants that could damage its components. Cover the machine with a protective cover when not in use to prevent dust and debris from accumulating on its surfaces.

In conclusion, regular maintenance is essential for ensuring the longevity and optimal performance of enameling machines. By following these maintenance tips, you can keep your machine running smoothly for years to come. Remember to clean the machine regularly, inspect it for damage, lubricate its moving parts, calibrate it as needed, and store it properly when not in use. With proper maintenance, your enameling machine will continue to produce high-quality enamel-coated products for years to come.