Exploration de l’utilisation d’une machine à émailler le fil de cuivre

En conclusion, les avantages de l’utilisation d’une machine d’émaillage de fils de cuivre sont nombreux et significatifs pour les industriels de l’industrie électrique. De l’amélioration de la qualité et de l’uniformité des revêtements d’émail à l’augmentation de l’efficacité de la production et à la réduction des déchets de matériaux, ces machines jouent un rôle crucial dans le processus de fabrication. En investissant dans une machine d’émaillage de fil de cuivre, les fabricants peuvent améliorer leurs capacités de production, répondre aux normes de l’industrie et, à terme, fournir à leurs clients des produits en fil émaillé de haute qualité.

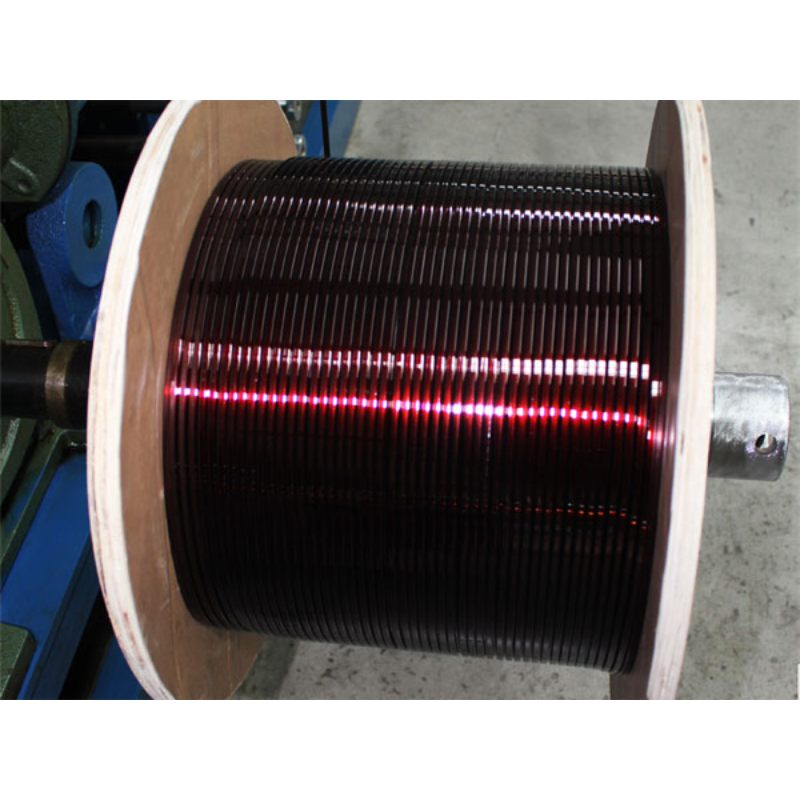

One of the key benefits of using a Copper Wire Enameling Machine is the efficiency and consistency it offers in the enameling process. These machines are equipped with precise temperature controls and speed settings, ensuring that the enamel is applied evenly and at the correct thickness. This level of control is crucial in producing high-quality enamel-coated wire that meets industry standards for electrical conductivity and insulation.

In addition to improving the quality of the enamel coating, copper wire enameling machines also help manufacturers increase their production output. These machines are capable of enameling wire at a much faster rate than manual methods, allowing for higher volumes of wire to be processed in a shorter amount of time. This increased efficiency not only saves time and labor costs but also enables manufacturers to meet tight production deadlines and fulfill large orders more quickly.

Another advantage of using a copper wire Vertical Enameling Machine is the reduction in material waste. With manual enameling methods, there is a higher risk of uneven coating thickness or defects in the enamel, which can result in the need to discard or rework the wire. By contrast, enameling machines are designed to apply the enamel consistently and accurately, minimizing the amount of waste generated during the production process. This not only helps manufacturers save on material costs but also contributes to a more sustainable and environmentally friendly manufacturing practice.

Furthermore, copper wire enameling machines are versatile tools that can be used to enamel a wide range of wire sizes and types. Whether manufacturers are working with thin gauge wire for electronics or thicker wire for industrial applications, these machines can be adjusted to accommodate different wire diameters and enamel formulations. This flexibility allows manufacturers to produce a variety of enamel-coated wire products to meet the diverse needs of their customers.

In conclusion, the benefits of using a copper wire enameling machine are numerous and significant for manufacturers in the electrical industry. From improving the quality and consistency of enamel coatings to increasing production efficiency and reducing material waste, these machines play a crucial role in the manufacturing process. By investing in a copper wire enameling machine, manufacturers can enhance their production capabilities, meet industry standards, and ultimately deliver high-quality enamel-coated wire products to their customers.