Table of Contents

Tips for Maintaining and Troubleshooting Enameling Machine

Horizontal enameling machines are essential equipment in the manufacturing industry for applying enamel coatings to various products. These machines are designed to provide a smooth and even coating of enamel on a horizontal surface, ensuring a high-quality finish. To ensure the optimal performance of a Horizontal Enameling Machine, regular maintenance and troubleshooting are necessary. In this article, we will discuss some tips for maintaining and troubleshooting horizontal enameling machines.

Regular maintenance is crucial for keeping a horizontal enameling machine in good working condition. One of the most important maintenance tasks is cleaning the machine regularly. Dust, dirt, and debris can accumulate on the machine’s components, affecting its performance. It is recommended to clean the machine after each use to prevent buildup and ensure smooth operation.

In addition to cleaning, it is essential to lubricate the moving parts of the machine regularly. Lubrication helps reduce friction between components, preventing wear and tear and extending the machine’s lifespan. Be sure to use the appropriate lubricant for each part of the machine to ensure optimal performance.

Inspecting the machine for any signs of wear or damage is also important. Check for loose or damaged parts, worn-out components, and any other issues that may affect the machine’s performance. Addressing these issues promptly can prevent further damage and costly repairs in the future.

Another crucial aspect of maintaining a horizontal enameling machine is calibrating it regularly. Calibration ensures that the machine is applying the enamel coating evenly and accurately. Improper calibration can result in uneven coatings, affecting the quality of the finished product. Follow the manufacturer’s guidelines for calibrating the machine to ensure consistent results.

Despite regular maintenance, horizontal enameling machines may encounter issues that require troubleshooting. One common problem is uneven coating application. This issue can be caused by a variety of factors, such as improper calibration, worn-out components, or clogged nozzles. To troubleshoot uneven coating application, check the machine’s calibration, inspect the components for wear or damage, and clean the nozzles to ensure proper enamel flow.

Another common issue with horizontal enameling machines is overheating. Overheating can be caused by a malfunctioning heating element, clogged ventilation system, or inadequate cooling. To troubleshoot overheating, check the heating element for any signs of damage, clean the ventilation system to ensure proper airflow, and monitor the machine’s temperature during operation.

In some cases, horizontal enameling machines may experience issues with enamel adhesion. Poor enamel adhesion can result in peeling, flaking, or bubbling of the coating, affecting the product’s quality. To troubleshoot enamel adhesion issues, check the enamel quality, adjust the machine’s settings for optimal adhesion, and ensure proper surface preparation before applying the coating.

In conclusion, maintaining and troubleshooting horizontal enameling machines is essential for ensuring their optimal performance and longevity. By following these tips, manufacturers can keep their machines in good working condition and prevent costly repairs. Regular cleaning, lubrication, inspection, calibration, and troubleshooting are key aspects of maintaining a horizontal enameling machine. By addressing issues promptly and taking preventive measures, manufacturers can ensure consistent and high-quality enamel coatings on their products.

Benefits of Using a Horizontal Enameling Machine for Industrial Applications

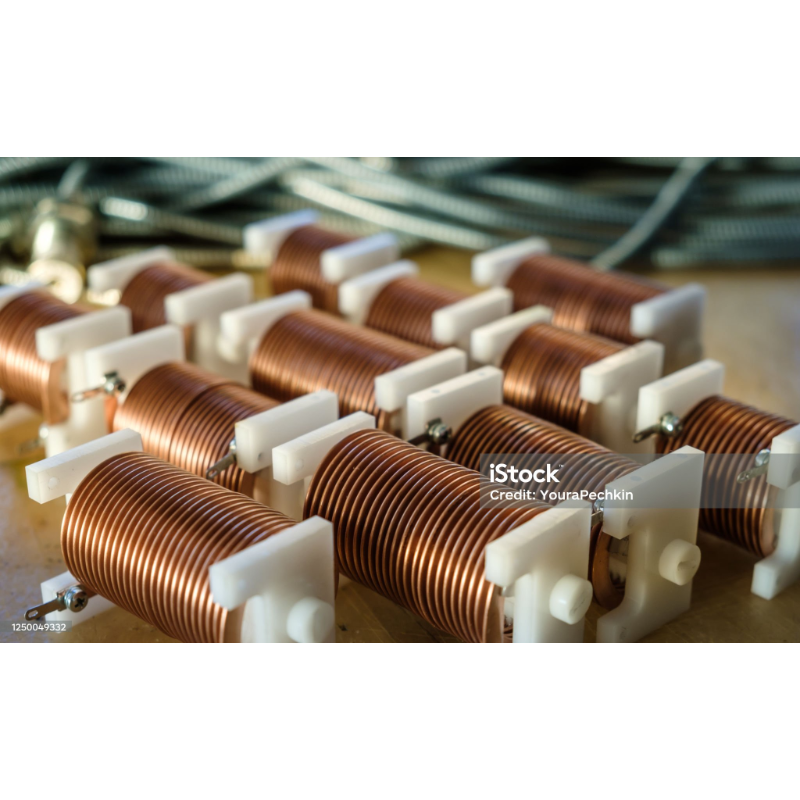

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and appearance. This process is commonly used in various industrial applications, such as manufacturing cookware, electrical components, and automotive parts. One of the key pieces of equipment used in the enameling process is the enameling machine, which helps to ensure a consistent and high-quality finish on the coated metal surfaces.

One type of enameling machine that is widely used in industrial applications is the horizontal enameling machine. This machine is designed to apply enamel coatings to metal surfaces in a horizontal orientation, as opposed to vertical enameling machines that apply coatings in a vertical orientation. There are several benefits to using a horizontal enameling machine for industrial applications.

One of the main advantages of using a horizontal enameling machine is its ability to handle large and heavy metal parts with ease. The horizontal orientation of the machine allows for easy loading and unloading of metal parts, making it ideal for processing large and bulky items. This can help to increase efficiency and productivity in industrial settings where large metal parts need to be coated with enamel.

Another benefit of using a horizontal Wire Enameling Plant is its versatility. These machines can be customized to accommodate different types of metal parts and enamel coatings, making them suitable for a wide range of industrial applications. Whether you are manufacturing small electrical components or large automotive parts, a horizontal enameling machine can be tailored to meet your specific needs.

In addition to handling large and heavy metal parts, horizontal enameling machines are also known for their precision and consistency. These machines are equipped with advanced technology that ensures a uniform and high-quality finish on coated metal surfaces. This can help to improve the overall quality of your products and enhance their durability and appearance.

Furthermore, horizontal enameling machines are designed for ease of maintenance and operation. These machines are built to withstand the rigors of industrial use and require minimal maintenance to keep them running smoothly. Additionally, they are easy to operate, with user-friendly controls that make it simple for operators to adjust settings and monitor the enameling process.

Overall, the benefits of using a horizontal enameling machine for industrial applications are clear. These machines offer a combination of efficiency, versatility, precision, and ease of maintenance that make them an essential piece of equipment for any industrial enameling operation. Whether you are manufacturing cookware, electrical components, or automotive parts, a horizontal enameling machine can help you achieve a consistent and high-quality finish on your coated metal surfaces.