Tips for Maintaining and Troubleshooting Aluminum Alloy Wire Drawing Machine

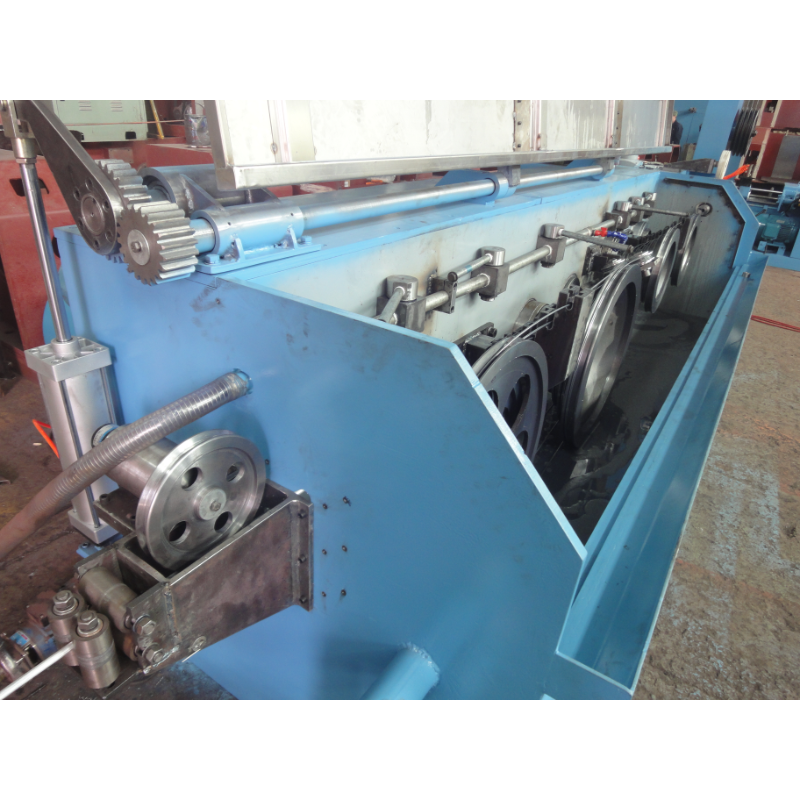

Aluminum wire drawing machines are essential equipment in the wire cable making industry. These machines are used to reduce the diameter of aluminum wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Proper maintenance and troubleshooting of the Aluminum Wire Drawing Machine are crucial to ensure its optimal performance and longevity.

Regular maintenance of the aluminum wire drawing machine is key to preventing breakdowns and ensuring smooth operation. One important aspect of maintenance is keeping the machine clean and free of debris. Dust, dirt, and other contaminants can build up on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues.

In addition to keeping the machine clean, it is important to regularly inspect and lubricate its moving parts. Over time, the components of the machine can wear down and become less efficient. By inspecting and lubricating these parts regularly, you can prevent premature wear and extend the life of the machine.

Another important aspect of maintaining an Aluminum Wire Making Machine is monitoring its electrical components. Electrical issues can cause the machine to malfunction or stop working altogether. Regularly checking the machine’s wiring, connections, and electrical components can help prevent these issues. If you notice any loose connections or frayed wires, it is important to address them immediately to prevent further damage.

Despite regular maintenance, aluminum wire drawing machines may still experience issues from time to time. When troubleshooting these issues, it is important to approach the problem systematically. Start by identifying the specific issue and then work backwards to determine the root cause.

One common issue with aluminum wire drawing machines is uneven wire diameter. This can be caused by a variety of factors, such as worn dies, improper lubrication, or incorrect machine settings. To troubleshoot this issue, start by checking the condition of the dies and lubricating the machine’s moving parts. If the issue persists, adjust the machine’s settings to ensure a more uniform wire diameter.

Another common issue with aluminum wire drawing machines is overheating. Overheating can be caused by a variety of factors, such as a lack of lubrication, worn components, or excessive friction. To troubleshoot this issue, start by checking the machine’s lubrication and adjusting it as needed. If the issue persists, inspect the machine’s components for signs of wear and replace any worn parts.

In conclusion, proper maintenance and troubleshooting of aluminum wire drawing machines are essential to ensure their optimal performance and longevity. By keeping the machine clean, inspecting and lubricating its moving parts, and monitoring its electrical components, you can prevent breakdowns and ensure smooth operation. When troubleshooting issues with the machine, approach the problem systematically and address the root cause to prevent further damage. By following these tips, you can keep your aluminum wire drawing machine running smoothly for years to come.