Table of Contents

Advantages of Using Wet Type Copper Wire Drawing Machine

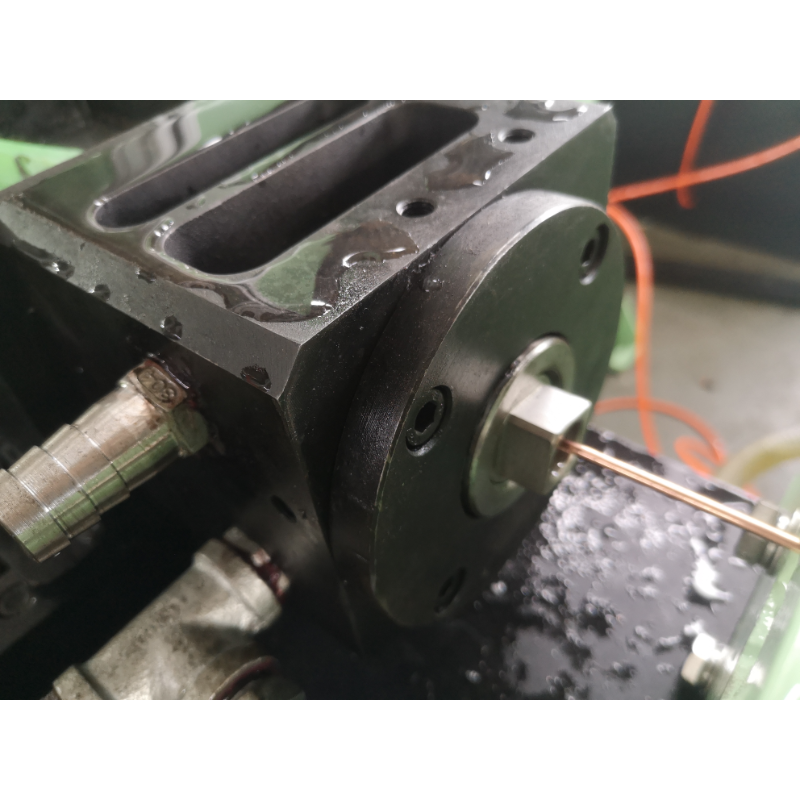

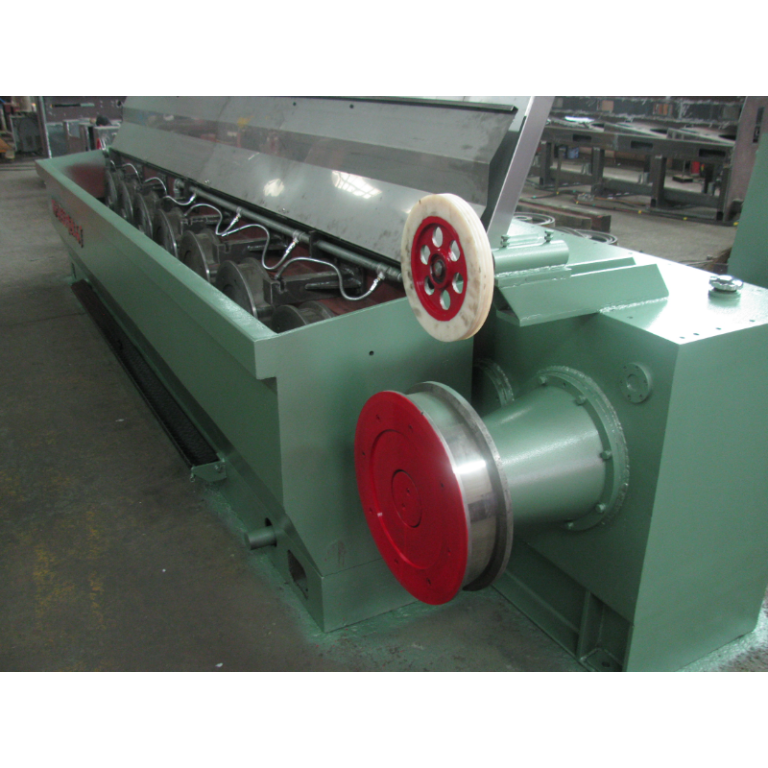

Copper wire drawing machines are essential equipment in the manufacturing industry for producing high-quality copper wires. These machines come in different types, with wet type copper wire drawing machines being one of the most popular choices. Wet type copper wire drawing machines use a coolant, typically water-based, to lubricate the wire and reduce friction during the drawing process. This article will discuss the advantages of using wet type Copper Wire Drawing Machine With Annealer in the manufacturing industry.

One of the main advantages of using wet type copper wire drawing machines is the improved quality of the finished product. The coolant used in these machines helps to reduce heat generated during the drawing process, which can lead to a smoother surface finish on the wire. This results in a higher quality product that is more suitable for use in various applications, such as electrical wiring or telecommunications.

In addition to improving the quality of the finished product, wet type Copper Fine Wire Drawing Machine With Annealer also help to increase the efficiency of the manufacturing process. The coolant used in these machines helps to reduce friction between the wire and the drawing dies, which can lead to faster drawing speeds and higher production rates. This can help manufacturers to meet their production targets more quickly and efficiently, ultimately leading to cost savings and increased profitability.

Another advantage of using wet type copper wire drawing machines is the reduced wear and tear on the equipment. The coolant used in these machines helps to lubricate the wire and drawing dies, which can help to extend the lifespan of the equipment. This can result in lower maintenance costs and reduced downtime for repairs, allowing manufacturers to keep their production lines running smoothly and efficiently.

Furthermore, wet type copper wire drawing machines are also more environmentally friendly compared to dry type machines. The coolant used in these machines is typically water-based, which is non-toxic and biodegradable. This means that manufacturers can reduce their environmental impact by using wet type machines in their production processes.

Overall, wet type copper wire drawing machines offer a range of advantages for manufacturers in the industry. From improved product quality and increased efficiency to reduced equipment wear and environmental benefits, these machines are a valuable investment for any manufacturing operation. By incorporating wet type copper wire drawing machines into their production processes, manufacturers can achieve higher quality products, increased efficiency, and reduced environmental impact, ultimately leading to greater success in the competitive manufacturing industry.

Maintenance Tips for Wet Type Copper Wire Drawing Machines

Wet type copper wire drawing machines are essential equipment in the manufacturing industry for producing high-quality copper wires. These machines are designed to pull copper rods through a series of dies to reduce their diameter and improve their quality. However, like any other machinery, wet type copper wire drawing machines require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tips for wet type Copper Multiwire Drawing Machine is to regularly clean and lubricate the machine. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the machine. By regularly cleaning the machine and applying lubricant to moving parts, you can prevent these issues and ensure smooth operation.

In addition to cleaning and lubricating the machine, it is also important to regularly inspect the machine for any signs of wear or damage. Check for loose or worn-out parts, such as belts, bearings, and dies, and replace them as needed. By addressing these issues promptly, you can prevent more serious problems from occurring and extend the lifespan of the machine.

Another important maintenance tip for wet type copper wire drawing machines is to monitor the machine’s operating temperature. Excessive heat can cause the machine’s components to expand, leading to increased friction and wear. To prevent overheating, ensure that the machine is properly ventilated and that cooling systems are functioning effectively. If the machine is running too hot, consider reducing the speed or load to prevent damage.

Regularly inspecting and replacing the machine’s coolant is also essential for maintaining optimal performance. Coolant helps to reduce friction and heat during the wire drawing process, preventing damage to the machine and ensuring high-quality wire production. Make sure to monitor coolant levels and quality regularly and replace it as needed to prevent overheating and maintain efficient operation.

Lastly, it is important to train your operators on proper machine maintenance and operation procedures. Ensure that they are familiar with the machine’s components and functions, as well as the importance of regular maintenance. By providing proper training, you can prevent operator errors that could lead to machine damage and downtime.

In conclusion, wet type copper wire drawing machines are valuable assets in the manufacturing industry, and proper maintenance is essential for ensuring their optimal performance and longevity. By following these maintenance tips, you can prevent damage, reduce downtime, and extend the lifespan of your machine. Regular cleaning, lubrication, inspection, monitoring of operating temperature, coolant replacement, and operator training are all key components of effective machine maintenance. By investing time and resources in proper maintenance, you can maximize the efficiency and productivity of your wet type copper wire drawing machine.