Table of Contents

Maintenance Tips for Water-Tank Wire Drawing Machine For Copper Wire

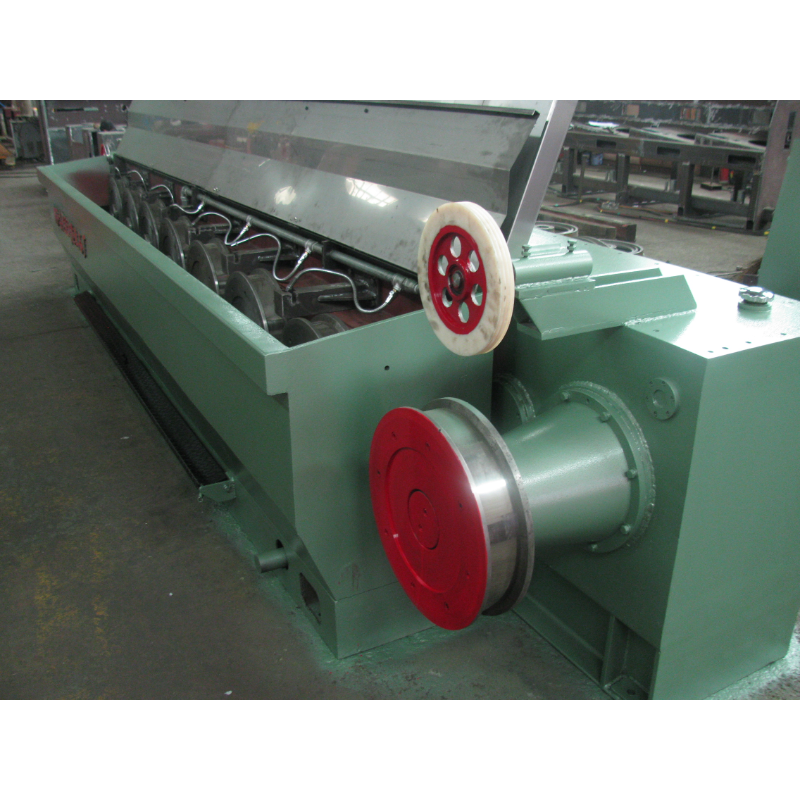

Water-tank wire drawing machines are essential equipment in the production of copper wire. These machines are used to reduce the diameter of copper rods by pulling them through a series of dies, resulting in a thinner and longer wire. Proper maintenance of water-tank wire drawing machines is crucial to ensure their optimal performance and longevity.

One of the key maintenance tasks for water-tank wire drawing machines is regular cleaning. Over time, dirt, dust, and debris can accumulate on the machine, affecting its efficiency and performance. It is important to clean the machine regularly to prevent these build-ups. Use a soft brush or cloth to remove any dirt or debris from the machine’s surface. Pay special attention to the wire drawing dies, as any build-up on these components can affect the quality of the wire produced.

In addition to cleaning, it is important to lubricate the moving parts of the water-tank wire drawing machine. Proper lubrication helps reduce friction between the components, ensuring smooth operation and preventing wear and tear. Use a high-quality lubricant recommended by the manufacturer to lubricate the machine’s moving parts. Be sure to follow the manufacturer’s guidelines on the frequency of lubrication to ensure optimal performance.

Regular inspection of the Copper Rod Casting and Making Machine is also essential for maintenance. Check for any signs of wear or damage on the machine’s components, such as the wire drawing dies, pulleys, and rollers. Replace any worn or damaged parts immediately to prevent further damage to the machine. Inspect the machine’s electrical components, such as the motor and control panel, for any signs of damage or malfunction. Address any issues promptly to prevent downtime and ensure the machine’s continued operation.

Another important maintenance task for water-tank wire drawing machines is monitoring the water level in the tank. The water in the tank helps cool the wire during the drawing process, preventing overheating and ensuring the quality of the wire produced. Check the water level regularly and top up as needed to maintain the optimal level for the machine’s operation. It is also important to clean the water tank periodically to remove any dirt or debris that may have accumulated.

Proper maintenance of water-tank wire drawing machines is essential to ensure their optimal performance and longevity. By following these maintenance tips, you can keep your machine in top condition and prevent costly repairs or downtime. Regular cleaning, lubrication, inspection, and monitoring of the water level are key tasks to include in your maintenance routine. Remember to follow the manufacturer’s guidelines and recommendations for maintenance to ensure the best results. With proper care and maintenance, your water-tank wire drawing machine will continue to produce high-quality copper wire for years to come.

Benefits of Using Water-tank Wire Drawing Machines for Copper Wire

Water-tank wire drawing machines are essential tools in the manufacturing process of copper wire. These machines offer numerous benefits that make them a popular choice among manufacturers. In this article, we will explore the advantages of using water-tank wire drawing machines for copper wire production.

One of the primary benefits of Copper Wire Drawing Machine is their ability to produce high-quality copper wire. The water cooling system in these machines helps to maintain a consistent temperature during the drawing process, which is crucial for achieving uniform wire diameter and surface finish. This results in copper wire that meets the highest quality standards and is suitable for a wide range of applications.

In addition to producing high-quality wire, water-tank wire drawing machines are also known for their efficiency. These machines are designed to operate at high speeds, allowing manufacturers to increase their production output significantly. The water cooling system helps to reduce friction and heat generation during the drawing process, which not only improves efficiency but also extends the lifespan of the drawing dies.

Another advantage of using water-tank wire drawing machines is their versatility. These machines can be used to draw copper wire of various diameters, making them suitable for a wide range of applications. Whether you need thin wire for electronics or thick wire for construction, water-tank wire drawing machines can meet your specific requirements.

Furthermore, Copper Fine Wire Drawing Machine With Annealer are easy to operate and maintain. The automated controls and user-friendly interface make it simple for operators to set up and monitor the drawing process. Additionally, the water cooling system helps to prevent overheating and reduce wear on the drawing dies, which minimizes the need for frequent maintenance and repairs.

One of the most significant benefits of using water-tank wire drawing machines is their cost-effectiveness. These machines are designed to maximize productivity while minimizing energy consumption and material waste. The high-speed operation and efficient cooling system help to reduce production costs and improve overall profitability for manufacturers.

In conclusion, water-tank wire drawing machines offer numerous benefits for copper wire production. From high-quality output and efficiency to versatility and cost-effectiveness, these machines are essential tools for manufacturers looking to optimize their wire drawing process. By investing in water-tank wire drawing machines, manufacturers can improve the quality of their copper wire, increase production output, and reduce operating costs.

How Water-tank Wire Drawing Machines Improve Efficiency in Copper Wire Production

Water-tank wire drawing machines are an essential tool in the production of copper wire. These machines play a crucial role in the manufacturing process by drawing the copper wire through a series of dies to reduce its diameter and improve its quality. By using water as a cooling medium, water-tank wire drawing machines are able to efficiently draw the copper wire without overheating, resulting in a higher quality end product.

One of the key benefits of using Copper Multiwire Drawing Machine is the improved efficiency they offer in the production of copper wire. These machines are designed to draw the wire at a consistent speed, ensuring that the wire is drawn evenly and with minimal breakage. This results in a higher yield of usable copper wire, reducing waste and increasing overall production efficiency.

In addition to their efficiency, water-tank wire drawing machines also offer a number of other advantages in the production of copper wire. By using water as a cooling medium, these machines are able to draw the wire at higher speeds without overheating, allowing for faster production times and increased output. This not only improves efficiency but also reduces production costs, making water-tank wire drawing machines a cost-effective solution for copper wire manufacturers.

Furthermore, water-tank wire drawing machines are able to produce copper wire with a higher level of quality and consistency. By drawing the wire through a series of dies in a controlled environment, these machines are able to produce wire with a uniform diameter and smooth surface finish. This results in a higher quality end product that meets the strict standards of the industry, ensuring that the copper wire is suitable for a wide range of applications.

Another advantage of using water-tank wire drawing machines is their versatility. These machines are able to draw copper wire in a wide range of diameters, making them suitable for a variety of applications. Whether producing thin wire for electronics or thicker wire for construction, water-tank wire drawing machines are able to meet the needs of copper wire manufacturers across different industries.

Overall, water-tank wire drawing machines are an essential tool in the production of copper wire. By offering improved efficiency, higher quality, and versatility, these machines play a crucial role in the manufacturing process. With their ability to draw wire at consistent speeds, reduce waste, and produce high-quality wire, water-tank wire drawing machines are a cost-effective solution for copper wire manufacturers looking to improve their production processes.