Inhoudsopgave

Voordelen van emailleermachines met hete luchtrecirculatie in China

Hoe emailleermachines met hete luchtrecirculatie een revolutie teweegbrengen in de emailleerindustrie in China

Over het geheel genomen zorgen emailleermachines met hete luchtrecirculatie voor een revolutie in de emailleerindustrie in China door fabrikanten een efficiëntere, kosteneffectievere en milieuvriendelijkere oplossing te bieden. Met hun superieure warmtedistributiemogelijkheden, energie-efficiëntie, veelzijdigheid en grotere productiecapaciteit helpen deze machines bedrijven hun activiteiten te stroomlijnen en de concurrentie voor te blijven. Nu de vraag naar hoogwaardige emaillecoatings blijft groeien, staan emailleermachines met heteluchtrecirculatie klaar om een sleutelrol te spelen bij het vormgeven van de toekomst van de industrie in China en daarbuiten.

How Hot Air Recirculation Enameling Machines are Revolutionizing the Enameling Industry in China

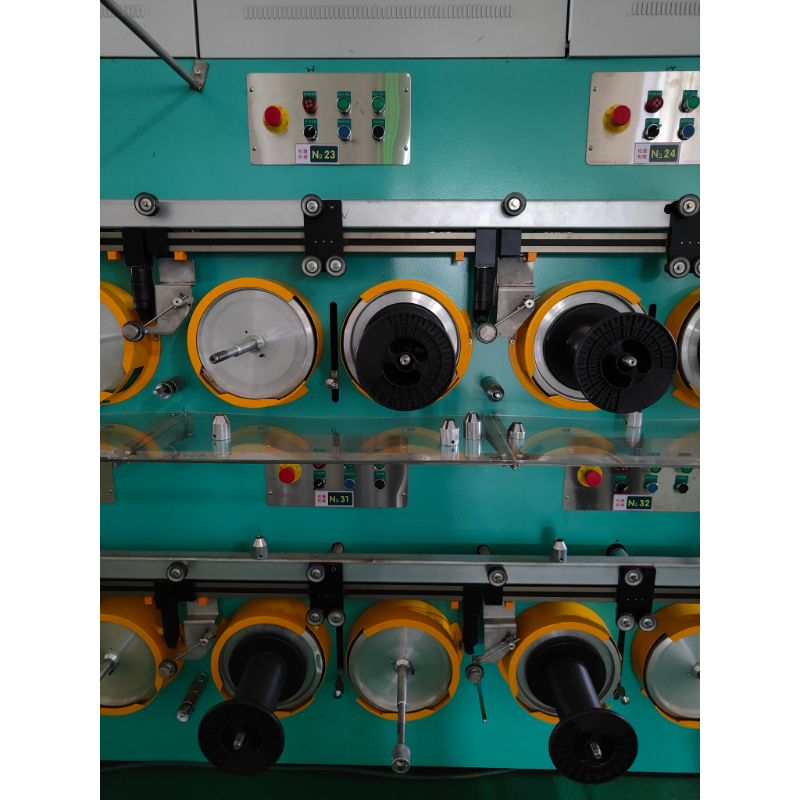

Hot Air Recirculation Enameling Machine for aluminum wire have been making waves in the enameling industry in China. These machines are revolutionizing the way enamel coatings are applied to various products, offering a more efficient and cost-effective solution for manufacturers. With the rise of automation and technological advancements, hot air recirculation enameling machines are becoming increasingly popular in China, providing a competitive edge to businesses looking to streamline their production processes.

One of the key benefits of hot air recirculation enameling machines is their ability to evenly distribute heat throughout the enameling process. This ensures that the enamel coating is applied uniformly, resulting in a high-quality finish that meets industry standards. By eliminating hot spots and cold spots, these machines can significantly reduce the risk of defects and imperfections in the final product, saving manufacturers time and money on rework and quality control.

In addition to their superior heat distribution capabilities, hot air recirculation Enameling Coating Machine also offer increased energy efficiency compared to traditional enameling methods. By recirculating hot air within the machine, manufacturers can reduce energy consumption and lower operating costs. This not only benefits the environment by reducing carbon emissions but also helps businesses improve their bottom line by cutting down on utility expenses.

Furthermore, hot air recirculation enameling machines are highly versatile and can be customized to meet the specific needs of different industries. Whether it’s automotive parts, household appliances, or industrial equipment, these machines can accommodate a wide range of products and materials, making them a valuable asset for manufacturers in China. With customizable settings and programmable controls, businesses can easily adjust the parameters of the enameling process to achieve the desired results, ensuring consistency and quality in every batch.

Another advantage of hot air recirculation enameling machines is their ability to increase production capacity and throughput. By automating the enameling process, manufacturers can significantly reduce cycle times and increase output, allowing them to meet growing demand and scale their operations efficiently. This is particularly beneficial for businesses in China looking to expand their market reach and compete on a global scale, as these machines can help them ramp up production without compromising on quality or consistency.

Overall, hot air recirculation enameling machines are revolutionizing the enameling industry in China by offering a more efficient, cost-effective, and environmentally friendly solution for manufacturers. With their superior heat distribution capabilities, energy efficiency, versatility, and increased production capacity, these machines are helping businesses streamline their operations and stay ahead of the competition. As the demand for high-quality enamel coatings continues to grow, hot air recirculation enameling machines are poised to play a key role in shaping the future of the industry in China and beyond.