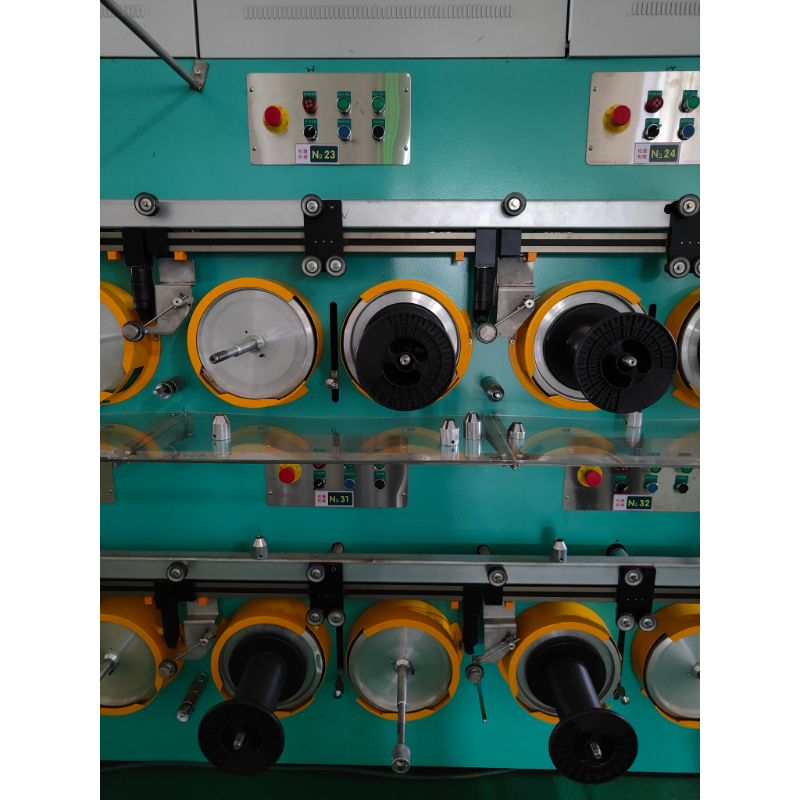

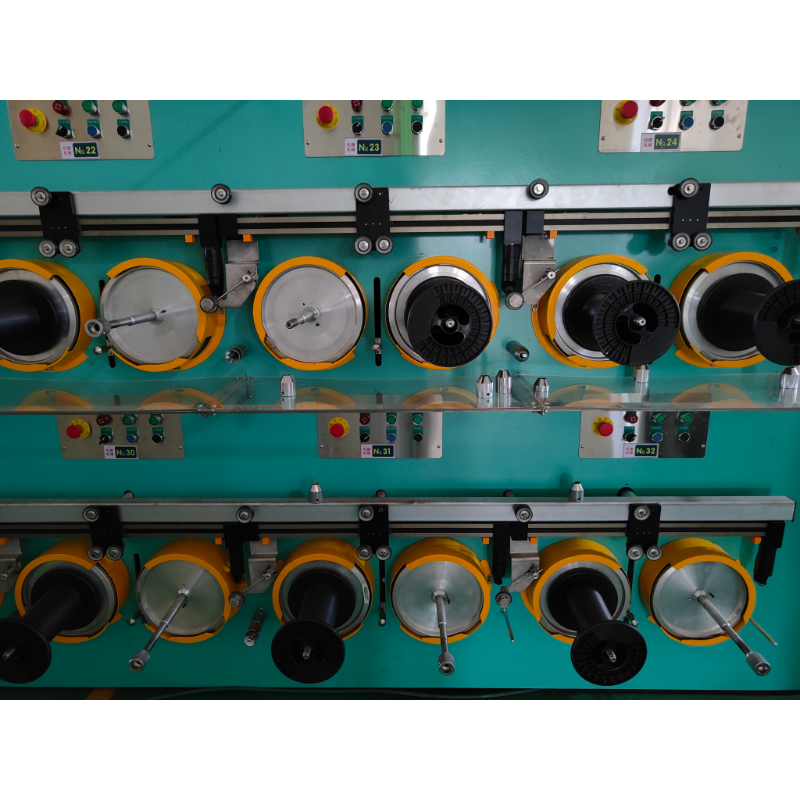

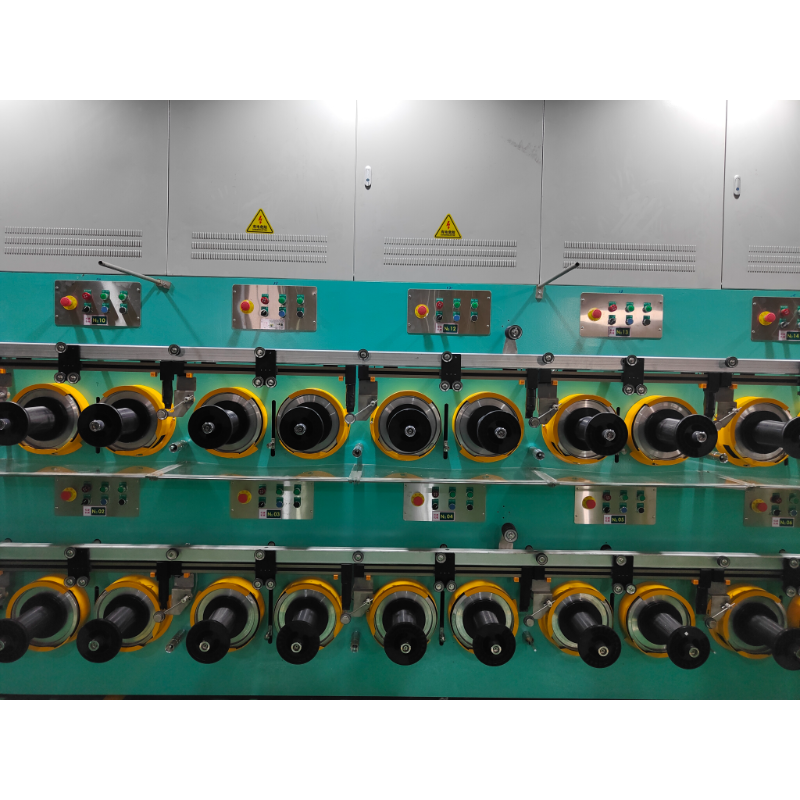

Enameling Machine,A Type Enameling Machine,Hot Air Recirculation Enameling Machine

Main advanteges:

· Low power consumption

· Zero pollution of exhaust

· Improvements of oven heat insulation

All insulating cottons adpot ceramic fiber material

· Lubricant oil coated with flow control

· Management functions

Earthnet interface available for remote control

· Wire temperature control

· Automatic boundary of traverse when winding up

· Self-bonding coating function optional

Copper Wire Enameling Machine,A Type Enameling Machine,Hot Air Recirculation Enameling Machine

Product parameter:

A type / Hot air recirculation enameling machine

| Oven Type | Size | Lines & Passes | Other Optional Configurations |

|

A3600 |

∮0.07–∮0.15 |

36 lines/8 passes 32 lines/9 passes 28 ines/10 passes |

1.Enamel applicator: 口felt

口felt + dies 2.take-up: 口semi-automatic changeover 口full-automatic changeover 3.max.take-up : 口 PT-15口 PT-25 4.main control system: 口meter type control mode 口touch screen type control mode with workmanship recording and inquiry functions 5.inspection system: 口full automatic laser gauge inspection system 口enamel coat automatic adjusting function 6.online inspection: 口on line pinhole inspection system 7.environmental protection: 口exhaust reburning system |

|

A3800 |

∮0.08–∮0.20 |

||

|

A4000 |

∮0.10–∮ 0.30 |

36 lines/8 passes 32 lines/9 passes 28 lines/10 passes |

|

|

A4200 |

∮0.15–∮0.35 |

||

|

A4500 |

∮0.25–∮0.60 |

32 lines/8 passes 28 lines/9 passes 24 lines/10 passes |

1.Enamel applicator: 口felt 口felt + dies

口spraying dies type 1. take-up: 口single shaft type口 PT-25口PT-60 口vertical take-up 口PT-90口PT-200 3.main control system: 口meter type control mode 口touch screen type control mode with workmanship recording and inquiry functions 4.online inspection: 口on line pinhole inspection system 口on line blisterinspection system 5.environmental protection optional ltem: 口exhaust reburning system 6. other optional items : 口four speeds type, can produce 4 sizes 口separate speed, separate traverse |

|

A5000 |

∮0.40–∮0.80 |

32 lines/8 passes 28 lines/9 passes 24 lines/10 passes |

Product feature:

· Low power consumption

· Zero pollution of exhaust

Secondly catalyst with special recipe, affective at 320 °C and above only, without extra electrical heating, ensure a complete decontamination, equal to zero pollution of exhaust.

· Improvements of oven heat insulation

All insulating cottons adpot ceramic fiber material

Thicken heaters insulation zone at top of oven

· Alternate the position of capstan roller and applicator, the final coating pass go to spooler across lower wire cooler, reduce wire temperature on bobbin.

· Lubricant oil coated with flow control

· Management functions

Earthnet interface available for remote control

Detection, storing and collection of power consumption quantity and unit power consumption

· Wire temperature control

· Automatic boundary of traverse when winding up

· Self-bonding coating function optional