Table of Contents

Step-by-Step Guide on How to Operate an Online Drawing Enameling Machine

An online drawing enameling machine is a sophisticated piece of equipment used in the manufacturing industry to apply a protective enamel coating to metal wires. This process helps to improve the durability and longevity of the wires, making them suitable for a wide range of applications. Operating an online drawing enameling machine requires precision and attention to detail to ensure that the enamel coating is applied evenly and effectively. In this article, we will provide a step-by-step guide on how to operate an online drawing enameling machine.

The first step in operating an online drawing Vertical Enameling Machine is to ensure that the machine is properly set up and calibrated. This includes checking that the wire feed mechanism is functioning correctly, the enamel coating is at the right temperature and viscosity, and the machine is clean and free from any debris. It is important to follow the manufacturer’s instructions for setting up the machine to ensure optimal performance.

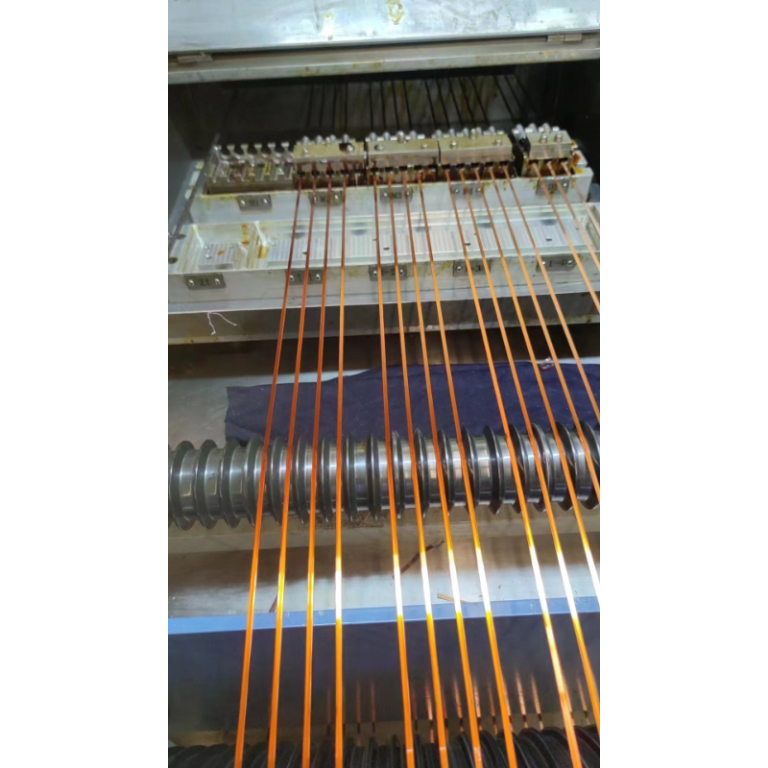

Once the machine is set up, the next step is to feed the metal wire through the machine’s drawing dies. The drawing dies are used to reduce the diameter of the wire and ensure a smooth and uniform surface for the enamel coating to be applied. It is important to adjust the tension and speed of the wire feed to ensure that the wire is drawn through the machine at the correct rate.

After the wire has been drawn through the machine, the next step is to apply the enamel coating. The enamel coating is typically applied using a spray nozzle or a dipping process, depending on the type of machine being used. It is important to ensure that the enamel coating is applied evenly and consistently to achieve the desired level of protection for the wire.

Once the enamel coating has been applied, the wire is then passed through a curing oven to dry and harden the enamel. The curing process is essential to ensure that the enamel coating adheres properly to the wire and provides the necessary protection against corrosion and wear.

After the wire has been cured, it is then wound onto a spool or reel for storage or further processing. It is important to handle the wire carefully to avoid damaging the enamel coating and ensure that it remains intact during storage and transportation.

In conclusion, operating an online drawing enameling machine requires careful attention to detail and precision to ensure that the enamel coating is applied effectively and efficiently. By following the steps outlined in this guide, you can successfully operate an online drawing enameling machine and produce high-quality enamel-coated wires for a variety of applications.

Benefits of Using an Online Drawing Enameling Machine for Jewelry Making

Craftsmanship in jewelry making has evolved significantly with the advent of technological advancements. One such innovation that has transformed the industry is the Online Drawing Enameling Machine. This sophisticated tool offers numerous benefits, making it a cornerstone in modern jewelry manufacturing.

At its core, the Online Drawing Enameling Machine combines precision engineering with automated processes, revolutionizing the way intricate designs are executed. Unlike traditional methods that require painstaking manual labor, this machine streamlines the enameling process, ensuring consistent quality and intricate detail in every piece produced.

One of the primary advantages of using a Wire Enameling Plant is its ability to achieve unparalleled precision. Through computer-aided design (CAD) and precise control mechanisms, jewelers can create intricate patterns and designs with microscopic accuracy. This precision not only enhances the aesthetic appeal of the jewelry but also reduces material waste, making the production process more efficient and cost-effective.

Moreover, the machine’s automation capabilities significantly enhance productivity. By automating repetitive tasks such as drawing and enameling, artisans can focus more on creative aspects and less on routine operations. This shift allows for faster turnaround times without compromising on quality, meeting the demands of a competitive market where speed and precision are paramount.

In terms of versatility, the Online Drawing Enameling Machine offers jewelers a wide range of design possibilities. Whether crafting delicate filigree patterns or bold, contemporary designs, the machine adapts to various styles and preferences with ease. This flexibility empowers artisans to explore new creative avenues and cater to diverse customer preferences, thereby expanding their market reach and enhancing customer satisfaction.

Furthermore, the machine’s efficiency translates into tangible environmental benefits. By minimizing material wastage and optimizing energy consumption, it supports sustainable practices within the jewelry industry. This eco-friendly approach not only aligns with global environmental goals but also enhances the brand reputation of jewelers committed to responsible manufacturing practices.

Another significant advantage of the Online Drawing Enameling Machine is its reliability. Built with robust materials and advanced technology, these machines are designed to withstand rigorous use in industrial settings. This durability ensures consistent performance over time, minimizing downtime and maintenance costs for jewelry manufacturers.

Additionally, the machine enhances the overall quality control process. By standardizing production parameters and minimizing human error, it ensures that each piece meets stringent quality standards. This reliability is crucial in maintaining brand integrity and customer trust, especially in luxury markets where craftsmanship and quality are non-negotiable.

In conclusion, the Online Drawing Enameling Machine represents a paradigm shift in the jewelry manufacturing industry. Its precision, automation, versatility, efficiency, and reliability collectively redefine the standards of craftsmanship and production efficiency. As technology continues to evolve, these machines will likely play an increasingly pivotal role in shaping the future of jewelry design and manufacturing, driving innovation and creativity to new heights. For jewelers aspiring to excel in a competitive market, embracing this transformative technology is not just an option but a strategic imperative for success in the modern era of jewelry making.