Table of Contents

How to Choose the Right Enameling Machine for Your Business

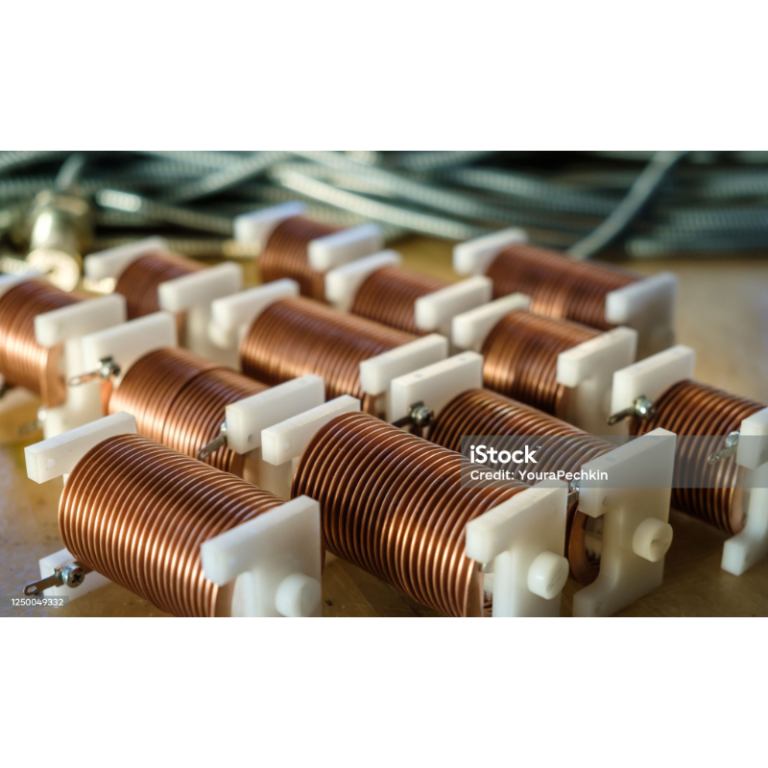

Enameling production lines are essential for businesses that specialize in creating enameled products such as cookware, jewelry, and decorative items. These production lines consist of various machines and equipment that are used to apply enamel coatings to metal surfaces, creating a durable and attractive finish. If you are in the market for an enameling production line, there are several factors to consider to ensure that you choose the right one for your business.

One of the first things to consider when choosing an Enameling Wire Production Line is the size and capacity of the line. The size of the production line will depend on the volume of products you plan to produce and the space available in your facility. It is important to choose a production line that can meet your production needs without taking up too much space or being underutilized.

Another important factor to consider is the type of enameling process used in the production line. There are several different enameling processes, including wet enamel, powder enamel, and electrostatic enamel. Each process has its own advantages and disadvantages, so it is important to choose a production line that uses the process that is best suited to your products and production requirements.

In addition to the size and type of enameling process, it is also important to consider the quality and reliability of the production line. Look for a production line that is manufactured by a reputable company with a track record of producing high-quality equipment. It is also important to consider the maintenance and support services offered by the manufacturer, as well as the availability of spare parts and technical support.

Cost is another important factor to consider when choosing an enameling production line. Production lines can vary widely in price depending on their size, capacity, and features. It is important to consider your budget and choose a production line that offers the best value for your money. Keep in mind that investing in a high-quality production line may cost more upfront but can save you money in the long run by reducing maintenance and downtime costs.

When choosing an enameling production line, it is also important to consider the compatibility of the line with your existing equipment and processes. Make sure that the production line can be easily integrated into your production workflow and that it is compatible with any other equipment you may already have. This will help to ensure a smooth transition to the new production line and minimize disruptions to your production process.

In conclusion, choosing the right enameling production line for your business is a crucial decision that can have a significant impact on your production efficiency and product quality. Consider factors such as size, capacity, enameling process, quality, reliability, cost, and compatibility when making your decision. By taking the time to carefully evaluate your options and choose a production line that meets your specific needs, you can ensure the success of your enameling business for years to come.

Tips for Maximizing Efficiency and Profitability with an Enameling Production Line

Enameling production lines are essential for businesses that specialize in creating enameled products such as cookware, jewelry, and decorative items. These production lines consist of various machines and equipment that work together to apply enamel coatings to metal surfaces, creating a durable and attractive finish. If you are in the market for an Enameling Coating Machine, there are several tips you can follow to maximize efficiency and profitability.

First and foremost, it is essential to invest in high-quality equipment. The quality of the machines and tools used in the production line will directly impact the quality of the finished products. Look for reputable manufacturers that offer reliable and durable equipment. While it may be tempting to cut costs by purchasing cheaper equipment, investing in high-quality machinery will pay off in the long run by reducing downtime and maintenance costs.

Another important tip for maximizing efficiency and profitability with an enameling production line is to streamline your production process. Analyze each step of the enameling process and look for ways to eliminate bottlenecks and inefficiencies. Consider implementing lean manufacturing principles to optimize your workflow and reduce waste. By streamlining your production process, you can increase output and reduce production costs, ultimately improving your bottom line.

In addition to streamlining your production process, it is crucial to train your employees properly. Wire Enameling Plant require skilled operators who understand how to operate the equipment safely and efficiently. Provide comprehensive training to your employees to ensure that they have the knowledge and skills necessary to operate the production line effectively. Regular training sessions and refresher courses can help keep your employees up to date on best practices and safety protocols.

Furthermore, it is essential to maintain your equipment regularly to ensure optimal performance. Regular maintenance and servicing can help prevent breakdowns and prolong the lifespan of your machinery. Create a maintenance schedule and stick to it to avoid costly repairs and downtime. Additionally, consider investing in predictive maintenance technologies that can help you identify potential issues before they escalate into major problems.

To further maximize efficiency and profitability with an enameling production line, consider implementing automation technologies. Automation can help streamline repetitive tasks, reduce human error, and increase production speed. Look for automation solutions that are compatible with your existing equipment and processes. While implementing automation may require an initial investment, the long-term benefits in terms of increased productivity and profitability can outweigh the costs.

Lastly, consider diversifying your product offerings to expand your customer base and increase sales. Enameling production lines can be used to create a wide range of products, so consider exploring new markets and applications for your enameled products. Conduct market research to identify potential opportunities and tailor your production line to meet the needs of different customer segments. By diversifying your product offerings, you can increase revenue and grow your business.

In conclusion, maximizing efficiency and profitability with an enameling production line requires careful planning, investment in high-quality equipment, streamlining production processes, training employees, regular maintenance, automation, and diversifying product offerings. By following these tips, you can optimize your production line and achieve success in the competitive enameling industry.