Table of Contents

Techniques for Achieving High-Quality Enamel Coating on T Type Multi-lines Low Speed On Line Drawing Enameling Machine

Enamel coating is a popular finishing technique used in various industries to enhance the appearance and durability of metal products. One of the key factors in achieving high-quality enamel coating is the type of enameling machine used. In this article, we will discuss the T Type Multi-lines Low Speed On Line Drawing Enameling Machine and the techniques for achieving superior enamel coating with this equipment.

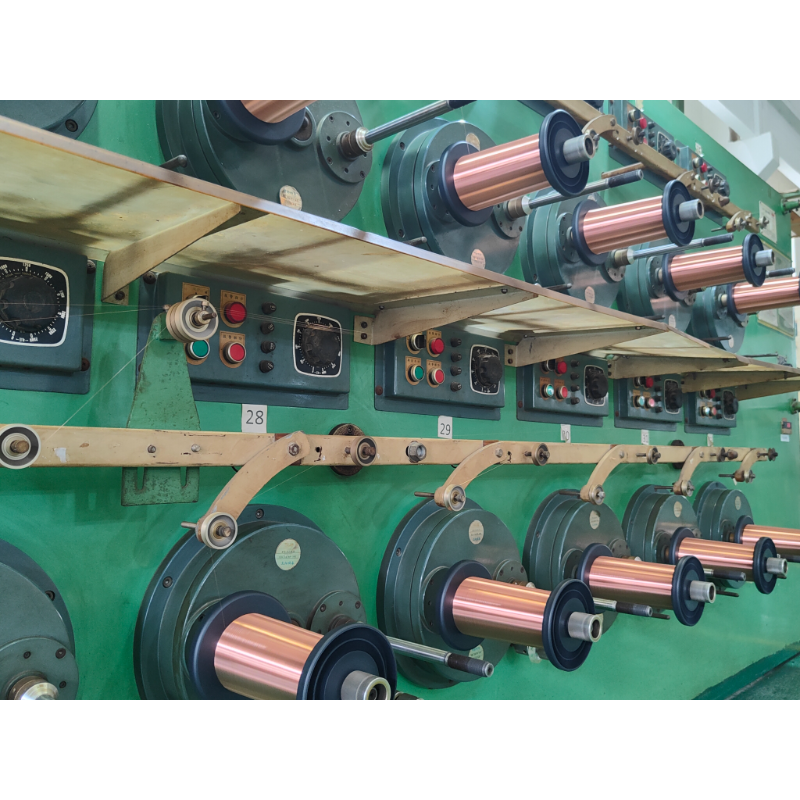

The T Type Multi-lines Low Speed On Line Drawing Enameling Machine is a specialized piece of equipment designed for applying enamel coatings to metal products. This machine is equipped with multiple lines for simultaneous coating, allowing for efficient and uniform coverage of the metal surface. The low speed of the machine ensures precise control over the coating process, resulting in a high-quality finish.

One of the key techniques for achieving high-quality enamel coating with the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is proper surface preparation. Before applying the enamel coating, it is essential to clean and degrease the metal surface to ensure good adhesion. Any contaminants or impurities on the surface can affect the quality of the enamel coating, leading to defects such as bubbles or uneven coverage.

Once the metal surface is properly prepared, the next step is to apply the enamel coating using the T Type Multi-lines Low Speed On Line Drawing Enameling Machine. The machine is equipped with multiple lines for simultaneous coating, allowing for efficient and uniform coverage of the metal surface. The low speed of the machine ensures precise control over the coating process, resulting in a smooth and even finish.

During the coating process, it is important to monitor the temperature and viscosity of the enamel to ensure optimal results. The T Type Multi-lines Low Speed On Line Drawing Enameling Machine is equipped with temperature and viscosity control systems to maintain the ideal conditions for applying the enamel coating. By monitoring these parameters closely, you can achieve a high-quality finish with consistent color and texture.

In addition to temperature and viscosity control, proper curing of the enamel coating is essential for achieving a durable and long-lasting finish. The T Type Multi-lines Low Speed On Line Drawing Enameling Machine is equipped with a curing oven that allows for precise control over the curing process. By following the recommended curing time and temperature settings, you can ensure that the enamel coating is fully cured and bonded to the metal surface.

Another important technique for achieving high-quality Enameling Coating Machine with the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is regular maintenance and cleaning of the equipment. Proper maintenance helps to prevent issues such as clogging or uneven coating, ensuring consistent results with each use. Regular cleaning of the machine also helps to prolong its lifespan and maintain optimal performance.

In conclusion, the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is a versatile and efficient piece of equipment for achieving high-quality enamel coating on metal products. By following the techniques outlined in this article, you can ensure that your enamel-coated products have a smooth, durable finish that meets the highest standards of quality. With proper surface preparation, temperature and viscosity control, curing, and maintenance, you can achieve superior results with the T Type Multi-lines Low Speed On Line Drawing Enameling Machine.

Maintenance Tips to Ensure Optimal Performance of T Type Multi-lines Low Speed On Line Drawing Enameling Machine

he T Type Multi-lines Low Speed On Line Drawing Enameling Machine is a crucial piece of equipment in the manufacturing industry. It is used to apply a protective enamel coating to various metal products, such as wires, cables, and pipes. To ensure that this machine operates at its optimal performance level, regular maintenance is essential.

One of the key maintenance tips for the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is to regularly inspect and clean the machine. Over time, dust, dirt, and debris can accumulate on the machine, which can affect its performance. By regularly cleaning the machine, you can prevent these issues from occurring and ensure that the machine continues to operate smoothly.

In addition to cleaning the machine, it is also important to regularly lubricate the moving parts of the machine. This will help to reduce friction and wear on the parts, which can extend the lifespan of the machine. It is recommended to use a high-quality lubricant that is specifically designed for use on enameling machines.

Another important maintenance tip for the Vertical Enameling Machine is to regularly check the tension of the wires or cables that are being fed through the machine. If the tension is too high or too low, it can cause the wires or cables to break or become damaged. By regularly checking and adjusting the tension, you can prevent these issues from occurring and ensure that the machine continues to operate efficiently.

It is also important to regularly inspect the heating elements of the machine. If the heating elements are not functioning properly, it can affect the quality of the enamel coating that is applied to the metal products. By regularly inspecting and replacing any faulty heating elements, you can ensure that the machine continues to produce high-quality enamel coatings.

Regularly calibrating the machine is another important maintenance tip for the T Type Multi-lines Low Speed On Line Drawing Enameling Machine. Calibrating the machine ensures that it is operating at the correct speed and temperature, which is essential for producing consistent and high-quality enamel coatings. It is recommended to calibrate the machine at least once a month to ensure optimal performance.

In addition to these maintenance tips, it is also important to train your staff on how to properly operate and maintain the T Type Multi-lines Low Speed On Line Drawing Enameling Machine. By providing your staff with the necessary training, you can ensure that they are able to identify and address any issues that may arise with the machine. This will help to prevent costly downtime and repairs in the future.

In conclusion, regular maintenance is essential for ensuring the optimal performance of the T Type Multi-lines Low Speed On Line Drawing Enameling Machine. By following these maintenance tips, you can extend the lifespan of the machine, prevent costly repairs, and ensure that it continues to produce high-quality enamel coatings. By investing time and resources into maintaining your machine, you can ensure that it remains a valuable asset to your manufacturing operation.

Comparison of Different Enameling Machines: Why T Type Multi-lines Low Speed On Line Drawing Enameling Machine Stands Out

Enameling machines are essential tools in the production of enameled wires, which are widely used in various industries such as electronics, automotive, and telecommunications. These machines come in different types and configurations, each designed to meet specific production requirements. One type of enameling machine that stands out is the T Type Multi-lines Low Speed On Line Drawing Enameling Machine.

This particular machine is known for its efficiency, reliability, and versatility in producing high-quality enameled wires. Unlike other enameling machines, the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is designed to handle multiple lines simultaneously, allowing for increased production capacity and efficiency. This feature is particularly beneficial for manufacturers who require large volumes of enameled wires in a short amount of time.

In addition to its multi-line capability, the T Type Enameling Machine is also equipped with a low-speed drawing system, which ensures a smooth and uniform coating of enamel on the wire. This results in a high-quality finish that meets industry standards and customer requirements. The low-speed drawing system also helps to minimize the risk of wire breakage or damage during the enameling process, further enhancing the machine’s reliability and performance.

Another key feature of the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is its on-line operation, which allows for real-time monitoring and control of the enameling process. This feature enables operators to make adjustments as needed to ensure consistent quality and performance. Additionally, the on-line operation reduces downtime and increases overall productivity, making the machine a cost-effective solution for manufacturers.

When compared to other enameling machines on the market, the T Type Multi-lines Low Speed On Line Drawing Enameling Machine offers several advantages that set it apart. Its multi-line capability, low-speed drawing system, and on-line operation make it a versatile and efficient choice for manufacturers looking to enhance their production capabilities and meet the demands of their customers.

In conclusion, the T Type Multi-lines Low Speed On Line Drawing Enameling Machine is a standout choice for manufacturers in need of a reliable and high-performance enameling machine. Its unique features and capabilities make it a valuable asset for increasing production capacity, ensuring quality finishes, and reducing downtime. With its efficiency, reliability, and versatility, this machine is a top contender in the market for enameling machines.