Table of Contents

Step-by-Step Guide on How to Properly Maintain a Vertical Enameling Machine

A vertical enameling machine is a crucial piece of equipment in the manufacturing industry, particularly in the production of enamel-coated products. To ensure the machine operates efficiently and effectively, proper maintenance is essential. In this step-by-step guide, we will outline the key maintenance tasks required to keep a vertical enameling machine in optimal working condition.

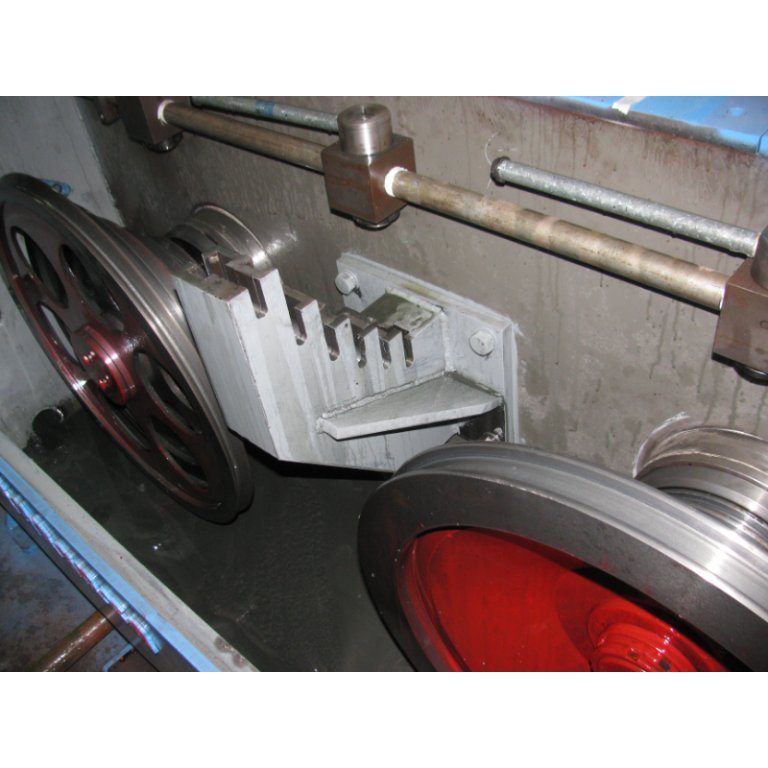

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, such as belts, chains, and rollers. Any issues should be addressed promptly to prevent further damage to the machine and ensure smooth operation.

Next, it is crucial to clean the machine regularly to remove any built-up dirt, dust, or debris. This can be done using a soft brush or cloth to gently wipe down the surfaces of the machine. It is also important to clean the enamel coating chamber to prevent any buildup that could affect the quality of the finished product.

In addition to cleaning, lubricating the moving parts of the machine is essential to prevent friction and ensure smooth operation. This includes applying lubricant to the chains, gears, and bearings of the machine. It is important to use the correct type of lubricant recommended by the manufacturer to avoid damaging the machine.

Another important maintenance task is to check the alignment of the machine regularly. This involves ensuring that all components are properly aligned to prevent any issues with the enamel coating process. Any misalignment should be corrected immediately to prevent further damage to the machine.

Furthermore, it is important to inspect the electrical components of the machine, such as the wiring and connections, to ensure they are in good working condition. Any frayed wires or loose connections should be repaired or replaced to prevent electrical issues that could affect the operation of the machine.

Lastly, it is important to schedule regular maintenance checks with a qualified technician to ensure the Wire Enameling Plant machine is operating at its best. This includes checking for any potential issues that may arise and addressing them before they become major problems. Regular maintenance checks can help prolong the life of the machine and prevent costly repairs down the line.

In conclusion, proper maintenance of a vertical enameling machine is essential to ensure it operates efficiently and effectively. By following this step-by-step guide, you can keep your machine in optimal working condition and prevent any issues that may arise. Remember to regularly inspect, clean, lubricate, align, and check the electrical components of the machine to keep it running smoothly. Additionally, scheduling regular maintenance checks with a qualified technician is crucial to prevent any major issues from occurring. By taking these steps, you can ensure your vertical enameling machine continues to produce high-quality enamel-coated products for years to come.

Advantages of Using Vertical Enameling Machine in Industrial Applications

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and resistance to corrosion. In industrial applications, enameling is commonly used to protect metal components from harsh environmental conditions and wear and tear. One of the key tools used in the enameling process is the vertical enameling machine.

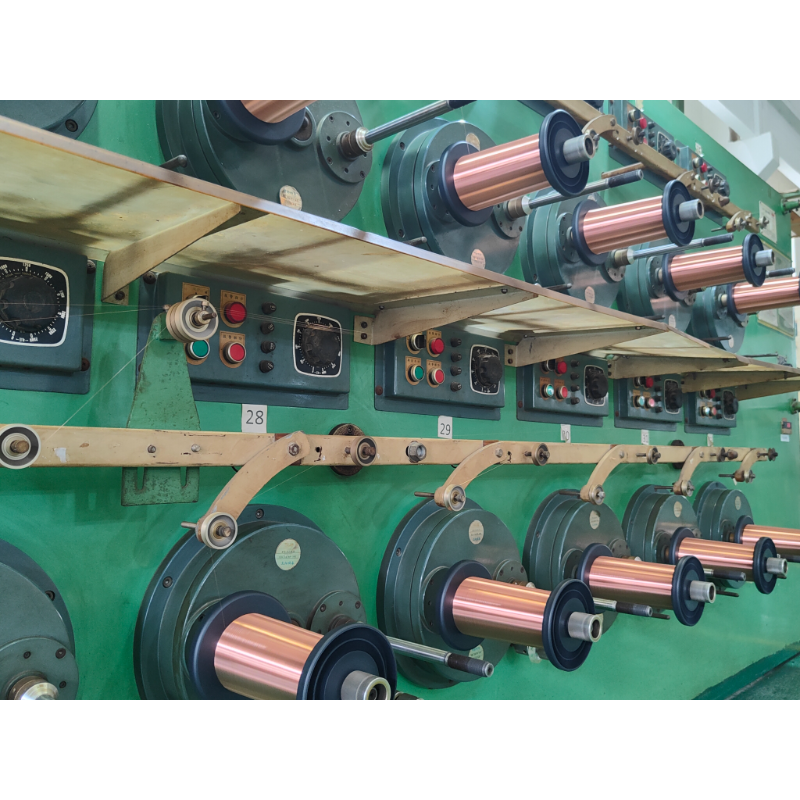

Vertical enameling machines are specifically designed for applying enamel coatings to metal surfaces in a vertical orientation. This design allows for efficient and uniform coating application, making them ideal for a wide range of industrial applications. There are several advantages to using vertical enameling machines in industrial settings.

One of the primary advantages of vertical enameling machines is their ability to coat large and complex metal components with ease. The vertical orientation of the machine allows for easy access to all sides of the metal surface, ensuring that the enamel coating is applied evenly and consistently. This is particularly important for industrial applications where the quality and durability of the coating are crucial.

Another advantage of vertical enameling machines is their efficiency and speed. These machines are equipped with advanced automation and control systems that allow for precise control over the coating process. This results in faster production times and higher throughput, making them ideal for high-volume industrial applications.

Vertical enameling machines also offer a high degree of flexibility and customization. These machines can be easily adjusted to accommodate different types of metal components and enamel coatings, allowing for a wide range of applications. This flexibility makes them a versatile tool for industrial manufacturers looking to meet the specific requirements of their products.

In addition to their efficiency and flexibility, vertical enameling machines are also known for their durability and reliability. These machines are built to withstand the rigors of industrial production environments, ensuring consistent performance and minimal downtime. This reliability is essential for industrial manufacturers looking to maintain high levels of productivity and quality in their operations.

Overall, vertical enameling machines offer a range of advantages for industrial applications. From their ability to coat large and complex metal components to their efficiency, flexibility, and reliability, these machines are a valuable tool for manufacturers looking to enhance the durability and performance of their products. With their advanced automation and control systems, vertical enameling machines are a cost-effective solution for industrial enameling needs.

In conclusion, vertical enameling machines are an essential tool for industrial manufacturers looking to protect metal components from corrosion and wear. With their efficiency, flexibility, and reliability, these machines offer a range of advantages that make them ideal for a wide range of industrial applications. Whether coating large and complex metal components or meeting specific product requirements, vertical enameling machines are a valuable asset for manufacturers looking to enhance the quality and durability of their products.