Table of Contents

How to Choose the Right Water-Tank Wire Drawing Machine For Copper Wire Manufacturing Business

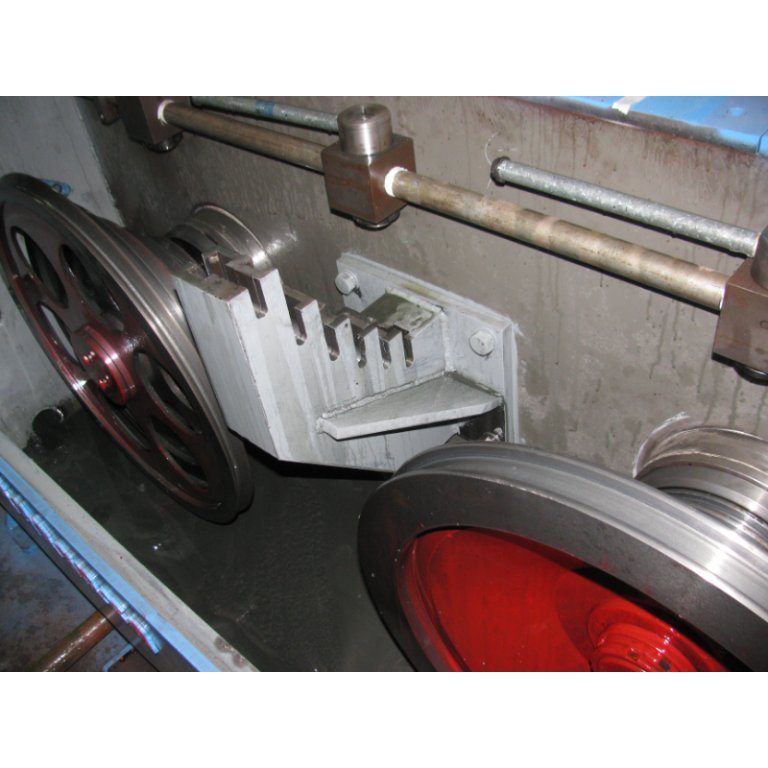

When it comes to manufacturing copper wire, having the right equipment is crucial to ensuring a high-quality end product. One essential piece of machinery for this process is a water-tank wire drawing machine. This machine is used to draw copper wire through a series of dies to reduce its diameter and improve its quality. Choosing the right Wet Type Drawing Machines For Copper Wire manufacturing business is essential to achieving optimal results.

There are several factors to consider when selecting a water-tank wire drawing machine. The first thing to consider is the size of the machine. The size of the machine will depend on the volume of copper wire you plan to produce. If you have a high production volume, you will need a larger machine with multiple drawing dies to accommodate the demand. On the other hand, if you have a smaller operation, a smaller machine with fewer drawing dies may be sufficient.

Another important factor to consider is the speed of the machine. The speed at which the wire is drawn through the dies will impact the quality of the finished product. A machine that operates at a higher speed may be able to produce more wire in a shorter amount of time, but it may also result in a lower quality product. It is important to find a balance between speed and quality to ensure that you are producing copper wire that meets your standards.

In addition to size and speed, it is also important to consider the material of the drawing dies. The material of the drawing dies will impact the durability and longevity of the machine. Tungsten carbide drawing dies are commonly used in water-tank wire drawing machines for copper wire manufacturing due to their hardness and resistance to wear. These drawing dies are able to withstand the high pressures and temperatures involved in the wire drawing process, resulting in a longer lifespan for the machine.

When choosing a Copper Wire Drawing Machine, it is also important to consider the maintenance and servicing requirements of the machine. Regular maintenance is essential to ensure that the machine operates efficiently and produces high-quality copper wire. It is important to choose a machine that is easy to maintain and service, with readily available replacement parts and a reliable service provider.

Finally, it is important to consider the cost of the machine. The cost of a water-tank wire drawing machine will depend on its size, speed, and features. It is important to consider your budget and the return on investment that the machine will provide for your business. While it may be tempting to choose a cheaper machine, it is important to consider the long-term costs and benefits of investing in a higher quality machine that will produce better results.

In conclusion, choosing the right water-tank wire drawing machine for your copper wire manufacturing business is essential to achieving high-quality results. Consider factors such as size, speed, material of drawing dies, maintenance requirements, and cost when selecting a machine. By carefully evaluating these factors, you can ensure that you are investing in a machine that will meet your production needs and produce copper wire of the highest quality.

Benefits of Using a Water-Tank Wire Drawing Machine for Copper Wire Production

Wire drawing is a process used in the manufacturing of various types of wire, including copper wire. This process involves pulling a metal wire through a series of dies to reduce its diameter and improve its quality. One of the key components in the wire drawing process is the Copper Fine Wire Drawing Machine With Annealer, which plays a crucial role in ensuring the efficiency and quality of the final product.

One type of wire drawing machine that is commonly used in the production of copper wire is the water-tank wire drawing machine. This type of machine offers several benefits that make it a popular choice among manufacturers.

One of the main advantages of using a water-tank wire drawing machine is its ability to cool the wire during the drawing process. As the wire is pulled through the dies, it generates heat due to friction. If the wire becomes too hot, it can lead to issues such as surface defects and reduced tensile strength. By using a water-tank wire drawing machine, the wire is continuously cooled as it passes through the water tank, helping to maintain its quality and integrity.

In addition to cooling the wire, the water-tank wire drawing machine also helps to lubricate the wire during the drawing process. Lubrication is essential for reducing friction between the wire and the dies, which in turn helps to prevent wear and tear on the equipment. By keeping the wire properly lubricated, the water-tank wire drawing machine helps to prolong the life of the dies and ensure a smooth and efficient drawing process.

Another benefit of using a water-tank wire drawing machine is its ability to control the speed of the drawing process. The speed at which the wire is pulled through the dies can have a significant impact on the quality of the final product. By using a water-tank wire drawing machine, manufacturers can easily adjust the speed of the drawing process to meet their specific production requirements. This level of control helps to ensure consistent quality and efficiency in the production of copper wire.

Furthermore, the water-tank wire drawing machine is also known for its versatility and flexibility. This type of machine can be easily adapted to accommodate different wire sizes and types, making it suitable for a wide range of applications. Whether manufacturers are producing thin or thick copper wire, the water-tank wire drawing machine can be adjusted to meet their specific needs.

Overall, the water-tank wire drawing machine offers a range of benefits that make it an ideal choice for manufacturers in the production of copper wire. From its ability to cool and lubricate the wire to its versatility and control over the drawing process, this type of machine plays a crucial role in ensuring the quality and efficiency of the wire drawing process. By investing in a water-tank wire drawing machine, manufacturers can improve their production processes and achieve high-quality results in the manufacturing of copper wire.