Table of Contents

Benefits of Investing in a Wire Enameling Plant Manufacturer

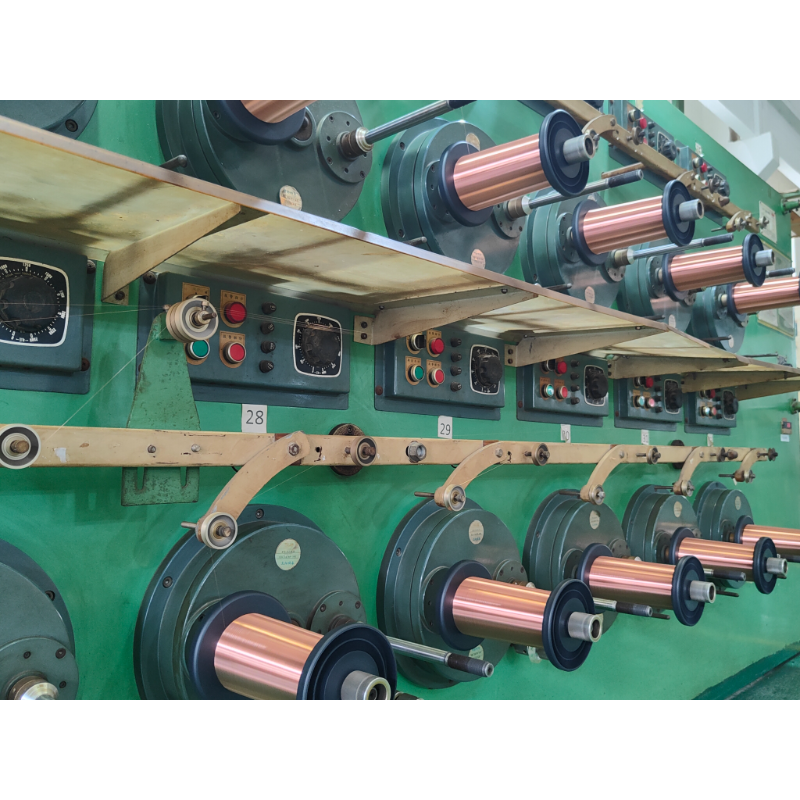

Investing in a wire enameling plant manufacturer can bring numerous benefits to businesses looking to enhance their production processes. Wire enameling is a crucial step in the manufacturing of electrical components, as it provides insulation and protection to the wire. By partnering with a reputable wire enameling plant manufacturer, businesses can ensure high-quality enameling services that meet industry standards.

One of the key benefits of investing in a wire enameling plant manufacturer is the ability to streamline production processes. By outsourcing enameling services to a specialized manufacturer, businesses can focus on their core operations without having to worry about the intricacies of wire enameling. This can lead to increased efficiency and productivity, as well as cost savings in the long run.

Furthermore, working with a wire enameling plant manufacturer can help businesses improve the quality of their products. Enameling is a delicate process that requires precision and expertise to ensure the insulation is applied evenly and effectively. By partnering with a manufacturer that specializes in wire enameling, businesses can benefit from the manufacturer’s knowledge and experience in producing high-quality enameling services.

In addition to improving product quality, investing in a wire Enameling Machine can also help businesses enhance their competitiveness in the market. By offering products with superior insulation and protection, businesses can attract more customers and gain a competitive edge over their rivals. This can lead to increased sales and revenue, as well as a stronger market position in the long term.

Another benefit of investing in a wire enameling plant manufacturer is the opportunity to access advanced technology and equipment. Enameling technology has evolved significantly in recent years, with manufacturers developing innovative solutions to improve the efficiency and quality of enameling processes. By partnering with a manufacturer that invests in cutting-edge technology, businesses can benefit from the latest advancements in wire enameling and stay ahead of the competition.

Moreover, working with a wire enameling plant manufacturer can help businesses reduce their environmental impact. Enameling processes can generate waste and emissions that can harm the environment if not properly managed. By partnering with a manufacturer that follows sustainable practices and uses eco-friendly enameling solutions, businesses can minimize their environmental footprint and contribute to a greener future.

Overall, investing in a wire enameling plant manufacturer can bring numerous benefits to businesses looking to enhance their production processes and improve the quality of their products. By partnering with a reputable manufacturer, businesses can streamline their operations, improve product quality, enhance competitiveness, access advanced technology, and reduce their environmental impact. These benefits can ultimately lead to increased efficiency, productivity, and profitability for businesses in the long run.

How to Choose the Right Wire Enameling Plant Manufacturer for Your Business

When it comes to choosing the right wire enameling plant manufacturer for your business, there are several factors to consider. From the quality of the equipment to the reputation of the manufacturer, making the right choice can have a significant impact on the success of your operations. In this article, we will discuss some key considerations to keep in mind when selecting a wire enameling plant manufacturer.

One of the first things to consider when choosing a wire enameling plant manufacturer is the quality of the equipment they offer. The quality of the equipment will directly impact the quality of the enamel coating on your wires, so it is essential to choose a manufacturer that offers high-quality, reliable equipment. Look for manufacturers that use top-of-the-line materials and technology in their equipment to ensure that you are getting the best possible results.

Another important factor to consider when choosing a wire Enameling Machine for Aluminum Wire manufacturer is their reputation in the industry. A manufacturer with a strong reputation is more likely to provide you with reliable equipment and excellent customer service. Look for manufacturers that have a track record of delivering high-quality products and meeting the needs of their customers. You can research manufacturers online, read reviews, and ask for recommendations from other businesses in the industry to help you make an informed decision.

In addition to quality and reputation, it is also essential to consider the cost of the equipment when choosing a wire enameling plant manufacturer. While it is important to invest in high-quality equipment, you also need to consider your budget and find a manufacturer that offers competitive pricing. Compare quotes from different manufacturers and consider the overall value that each one offers to determine which manufacturer is the best fit for your business.

When choosing a wire enameling plant manufacturer, it is also important to consider their level of customer service and support. A manufacturer that provides excellent customer service will be able to assist you with any issues that may arise and ensure that your equipment is running smoothly. Look for manufacturers that offer training, maintenance services, and technical support to help you get the most out of your equipment.

Finally, consider the location of the manufacturer when choosing a wire enameling plant manufacturer. Working with a manufacturer that is located close to your business can make it easier to access support and services when needed. Additionally, choosing a local manufacturer can help reduce shipping costs and lead times, making it more convenient for you to get the equipment you need.

In conclusion, choosing the right wire enameling plant manufacturer for your business is a crucial decision that can have a significant impact on your operations. Consider factors such as equipment quality, reputation, cost, customer service, and location when making your decision. By taking the time to research and compare different manufacturers, you can find a manufacturer that meets your needs and helps you achieve success in your wire enameling operations.