Table of Contents

How to Choose the Right Enameling Wire Production Line for Your Business

Wire enameling is a process that involves coating a wire with a thin layer of insulation to protect it from corrosion and wear. This process is essential in the manufacturing of electrical components, such as motors, transformers, and generators. If you are in the market for a wire enameling production line, there are several factors to consider to ensure that you choose the right equipment for your business.

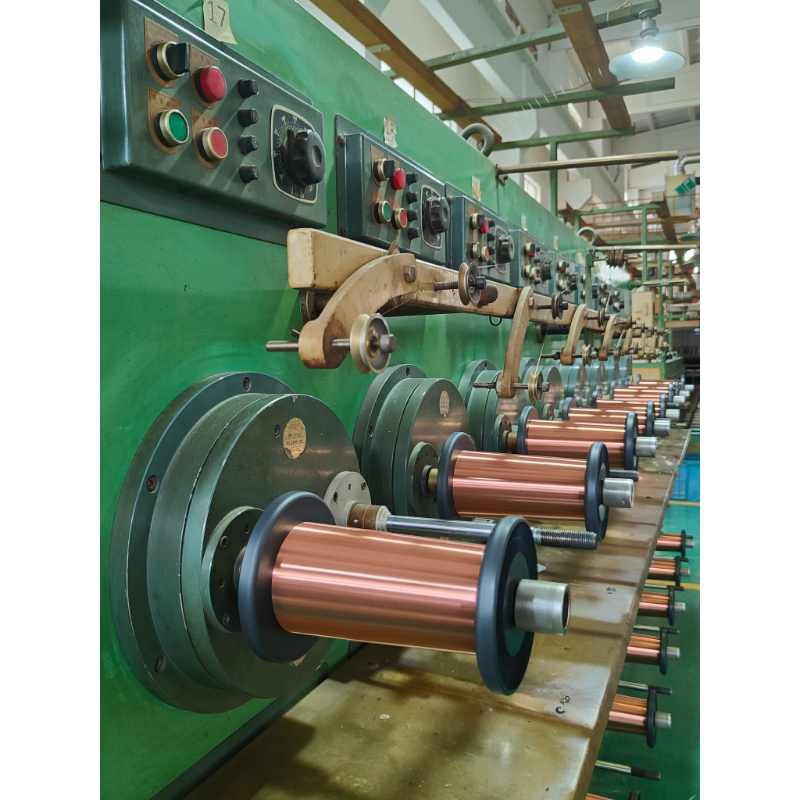

One of the first things to consider when selecting a wire enameling production line is the type of wire you will be working with. Different types of wire require different enameling processes, so it is important to choose a production line that is compatible with the wire you will be using. For example, if you will be working with copper wire, you will need a production line that is designed to handle the high temperatures required for enameling copper.

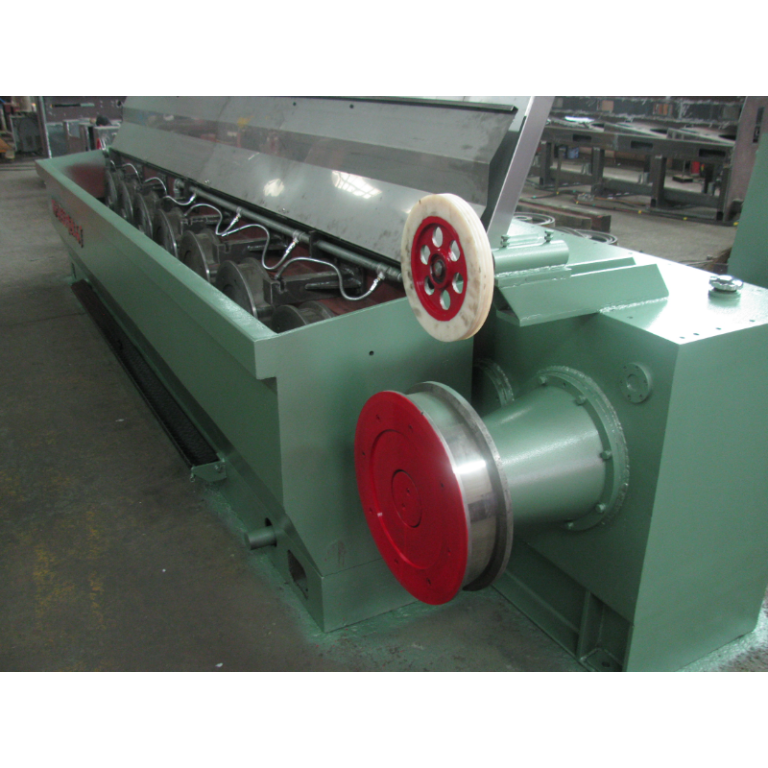

Another important factor to consider is the size of the wire Enameling Machine. The size of the production line will depend on the volume of wire you will be processing and the space available in your facility. It is important to choose a production line that is large enough to meet your production needs but not so large that it takes up unnecessary space in your facility.

In addition to size, it is also important to consider the speed and efficiency of the wire enameling production line. A production line that is slow or inefficient can lead to bottlenecks in your production process and ultimately cost you time and money. Look for a production line that is designed for high-speed enameling and has features that improve efficiency, such as automatic wire feeding and cutting.

When choosing a wire enameling production line, it is also important to consider the quality of the equipment. Look for a production line that is made from high-quality materials and is built to last. Investing in a high-quality production line may cost more upfront, but it will save you money in the long run by reducing maintenance and repair costs.

Finally, consider the reputation of the manufacturer when choosing a wire enameling production line. Look for a manufacturer with a proven track record of producing high-quality equipment and providing excellent customer service. Reading reviews and talking to other businesses that have purchased equipment from the manufacturer can help you make an informed decision.

In conclusion, choosing the right wire enameling production line for your business is essential to ensuring the success of your production process. Consider factors such as the type of wire you will be working with, the size of the production line, speed and efficiency, quality of the equipment, and the reputation of the manufacturer. By carefully considering these factors, you can select a wire enameling production line that meets your production needs and helps your business thrive.

Tips for Maintaining and Optimizing a Wire Enameling Production Line

Wire enameling production lines are essential for manufacturing high-quality enameled wires used in various industries such as electronics, automotive, and telecommunications. These production lines consist of several components that work together to apply enamel coating to wires, ensuring their durability and electrical insulation properties. If you are in the market for a wire enameling production line, there are several factors to consider to ensure its optimal performance and longevity.

One of the key aspects of maintaining a Flat Wire Enameling Machine is regular cleaning and lubrication of its components. Over time, dust, dirt, and debris can accumulate on the machine, leading to decreased efficiency and potential breakdowns. By implementing a regular cleaning schedule and using appropriate lubricants, you can prevent these issues and extend the lifespan of your production line.

In addition to cleaning and lubrication, it is important to regularly inspect the components of the production line for any signs of wear or damage. Frayed wires, loose connections, and worn-out parts can lead to malfunctions and production delays. By conducting routine inspections and addressing any issues promptly, you can prevent costly repairs and downtime.

Another important aspect of maintaining a wire enameling production line is proper training for operators. Operating a production line requires specialized skills and knowledge to ensure its optimal performance. By providing comprehensive training to your operators, you can minimize errors, improve efficiency, and maximize the output of your production line.

Optimizing a wire enameling production line involves fine-tuning its settings and parameters to achieve the desired results. By experimenting with different speeds, temperatures, and coating thicknesses, you can find the optimal combination that meets your production requirements. Regularly monitoring and adjusting these settings can help you achieve consistent quality and efficiency in your production process.

Investing in quality materials and components is also crucial for maintaining and optimizing a wire enameling production line. Using high-quality enamel coatings, wires, and other consumables can improve the performance and longevity of your production line. By sourcing materials from reputable suppliers and conducting quality checks, you can ensure the reliability and consistency of your production process.

Lastly, regular maintenance and servicing of your wire enameling production line are essential for its long-term performance. By scheduling routine maintenance checks and servicing by qualified technicians, you can identify and address any potential issues before they escalate. This proactive approach can help you avoid costly repairs and minimize downtime, ensuring the smooth operation of your production line.

In conclusion, maintaining and optimizing a wire enameling production line requires a combination of regular cleaning, inspection, training, optimization, and quality control measures. By following these tips, you can ensure the optimal performance and longevity of your production line, ultimately leading to increased productivity and profitability for your business. If you are in the market for a wire enameling production line, be sure to consider these factors to make an informed decision and maximize the return on your investment.