Benefits of Upgrading to an Intermediate Aluminum Wire Drawing Machine

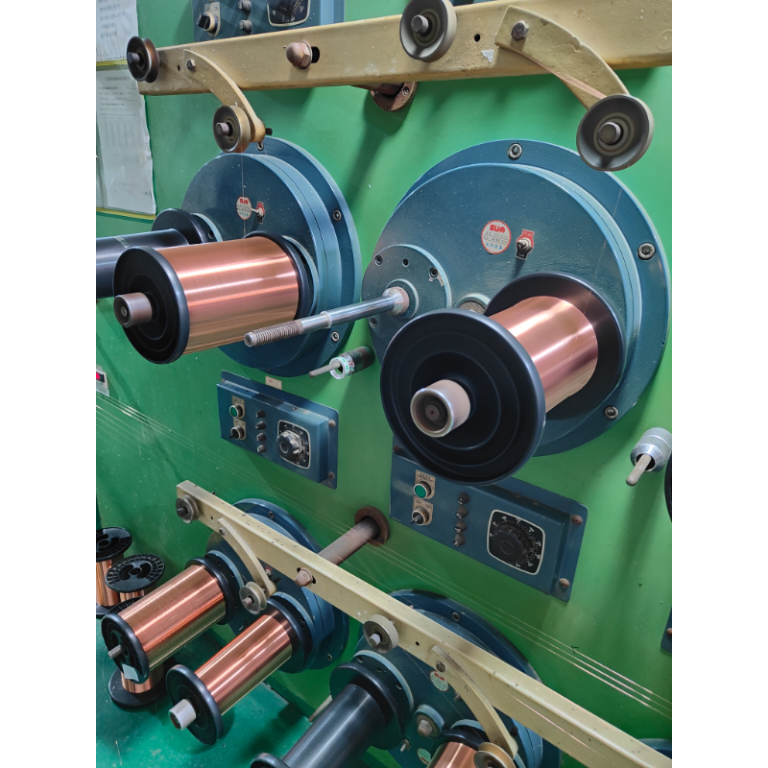

Aluminum wire drawing machines are essential equipment in the manufacturing industry for producing high-quality aluminum wires of various sizes and diameters. These machines are used to reduce the diameter of aluminum rods or wires by pulling them through a series of dies to achieve the desired size. Upgrading to an intermediate aluminum wire drawing machine can offer several benefits for manufacturers looking to improve their production processes and increase efficiency.

One of the key benefits of upgrading to an intermediate aluminum wire drawing machine is the ability to achieve higher production speeds. These machines are designed to operate at faster speeds compared to entry-level machines, allowing manufacturers to increase their output and meet growing demand. With a higher production speed, manufacturers can produce more aluminum wires in a shorter amount of time, leading to increased productivity and profitability.

In addition to higher production speeds, intermediate Aluminum Alloy Wire Drawing Machine also offer improved accuracy and precision. These machines are equipped with advanced technology and features that allow for more precise control over the wire drawing process. This results in a higher quality finished product with consistent diameter and surface finish, meeting the strict quality standards required by customers in various industries.

Another benefit of upgrading to an intermediate aluminum wire drawing machine is the ability to work with a wider range of aluminum alloys. These machines are designed to handle a variety of aluminum alloys, including high-strength alloys and specialty alloys, allowing manufacturers to expand their product offerings and cater to a broader range of customer needs. By upgrading to a machine that can process different types of aluminum alloys, manufacturers can diversify their product portfolio and tap into new markets.

Furthermore, intermediate aluminum wire drawing machines are more energy-efficient compared to older models, helping manufacturers reduce their energy consumption and operating costs. These machines are equipped with energy-saving features and technologies that optimize the wire drawing process and minimize energy wastage. By upgrading to a more energy-efficient machine, manufacturers can lower their production costs and improve their overall profitability.

Additionally, intermediate aluminum wire drawing machines are designed for easy maintenance and servicing, reducing downtime and ensuring continuous operation. These machines are built with durable components and materials that require minimal maintenance, saving manufacturers time and money on repairs and replacements. With regular maintenance and servicing, manufacturers can prolong the lifespan of their machine and maximize its performance for years to come.

In conclusion, upgrading to an intermediate aluminum wire drawing machine offers several benefits for manufacturers looking to enhance their production processes and improve efficiency. From higher production speeds and improved accuracy to the ability to work with a wider range of aluminum alloys, these machines provide manufacturers with the tools they need to stay competitive in the market. With energy-efficient operation and easy maintenance, upgrading to an intermediate aluminum wire drawing machine is a smart investment for manufacturers looking to boost their productivity and profitability.