Table of Contents

Investing in a Vertical Enameling Machine for Industrial Applications

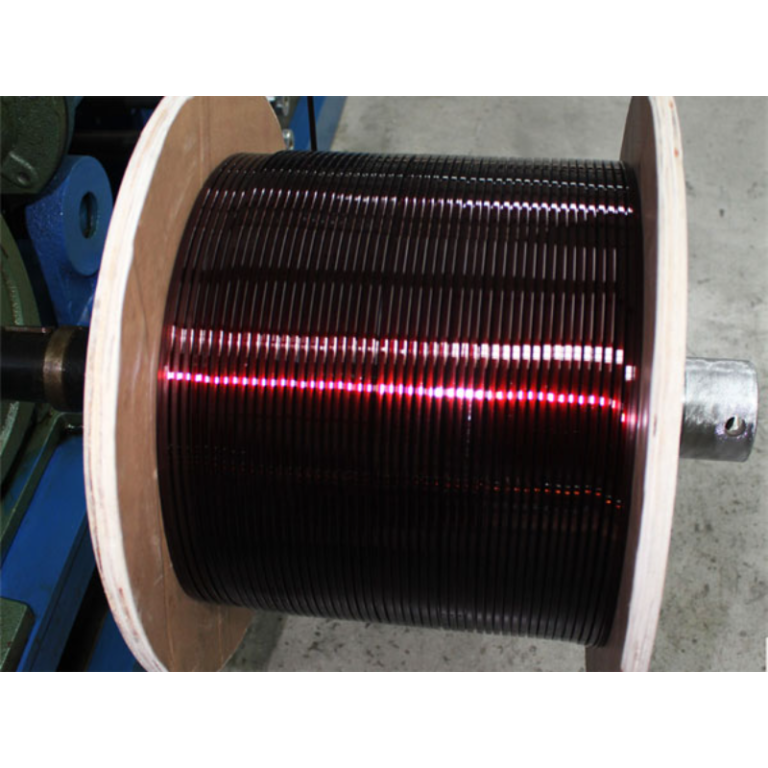

Enameling is a process that involves applying a protective coating to metal surfaces to enhance their durability and resistance to corrosion. This process is commonly used in various industrial applications, such as in the manufacturing of cookware, automotive parts, and electrical components. One of the key pieces of equipment used in the enameling process is a vertical enameling machine.

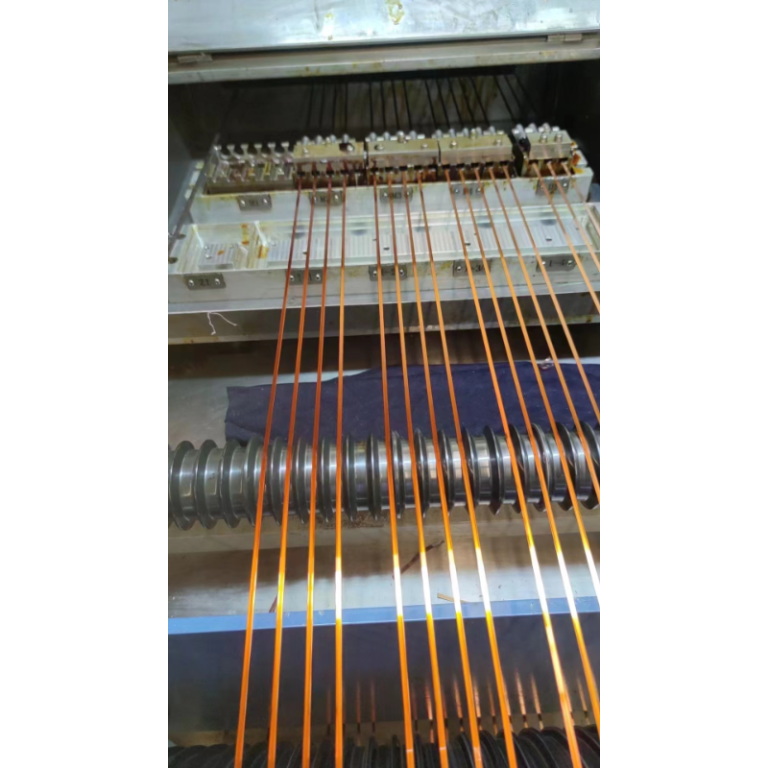

Vertical enameling machines are specifically designed to coat metal surfaces with enamel in a vertical orientation. This design allows for more efficient and uniform coating of the metal surface, resulting in a higher quality finish. Investing in a vertical enameling machine for industrial applications can offer a range of benefits, including increased productivity, improved product quality, and reduced operating costs.

One of the primary benefits of investing in a Wire Enameling Plant is increased productivity. These machines are designed to handle large volumes of metal parts efficiently, allowing for faster processing times and higher production output. The vertical orientation of the machine also allows for easy loading and unloading of parts, further streamlining the enameling process. This increased productivity can help industrial manufacturers meet tight production deadlines and fulfill customer orders more quickly.

In addition to increased productivity, investing in a vertical enameling machine can also lead to improved product quality. The vertical orientation of the machine ensures that the enamel coating is applied evenly and consistently across the entire surface of the metal part. This results in a more uniform finish that is free from defects such as drips, runs, or uneven coverage. The high precision and control offered by vertical enameling machines can help industrial manufacturers achieve a higher level of product quality and consistency, leading to greater customer satisfaction and loyalty.

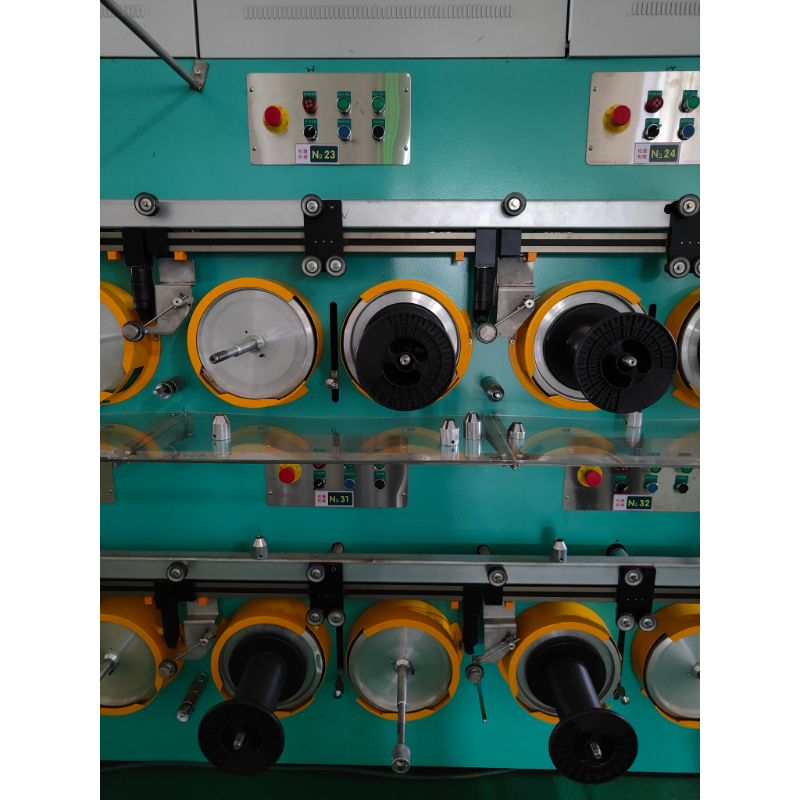

Another benefit of investing in a vertical enameling machine is the potential for reduced operating costs. These machines are designed to be highly efficient and energy-saving, helping industrial manufacturers lower their overall production costs. The vertical orientation of the machine also allows for better utilization of floor space, making it ideal for manufacturers with limited space in their facilities. By investing in a vertical enameling machine, industrial manufacturers can reduce waste, improve efficiency, and lower their operating costs, ultimately leading to increased profitability.

Overall, investing in a vertical enameling machine for industrial applications can offer a range of benefits, including increased productivity, improved product quality, and reduced operating costs. These machines are designed to handle large volumes of metal parts efficiently, ensuring a high level of precision and control in the enameling process. By investing in a vertical enameling machine, industrial manufacturers can enhance their production capabilities, meet customer demands, and achieve greater success in the competitive marketplace.

How to Choose the Right Vertical Enameling Machine Manufacturer for Your Business

When it comes to choosing the right vertical enameling machine manufacturer for your business, there are several factors to consider. From the quality of the machines to the reputation of the manufacturer, making the right choice can have a significant impact on the success of your business. In this article, we will discuss some key considerations to keep in mind when selecting a vertical enameling machine manufacturer.

One of the first things to consider when choosing a vertical Enameling Wire Production Line is the quality of their machines. You want to make sure that the manufacturer you choose produces high-quality machines that will meet your business’s needs. Look for manufacturers that have a reputation for producing durable, reliable machines that are built to last. You may also want to consider the technology and features that are available on the machines, as this can impact the efficiency and effectiveness of your operations.

Another important factor to consider when choosing a vertical enameling machine manufacturer is their reputation in the industry. Look for manufacturers that have a track record of delivering quality machines and excellent customer service. You can research the manufacturer online, read reviews from other customers, and even reach out to other businesses that have worked with the manufacturer to get a sense of their reputation. A manufacturer with a strong reputation is more likely to provide you with a positive experience and high-quality machines.

In addition to quality and reputation, you should also consider the cost of the machines when choosing a vertical enameling machine manufacturer. While it’s important to find a manufacturer that offers competitive pricing, you should also be wary of manufacturers that offer machines at significantly lower prices than their competitors. In some cases, lower prices may indicate lower quality machines or poor customer service. It’s important to strike a balance between cost and quality when choosing a manufacturer.

When selecting a vertical enameling machine manufacturer, it’s also important to consider the level of customer support and service they provide. Look for manufacturers that offer comprehensive customer support, including training, maintenance, and troubleshooting services. A manufacturer that is responsive to your needs and provides ongoing support can help ensure that your machines operate smoothly and efficiently.

Finally, when choosing a vertical enameling machine manufacturer, consider the manufacturer’s experience and expertise in the industry. Look for manufacturers that have a long history of producing enameling machines and have a deep understanding of the industry. Manufacturers with experience are more likely to understand your business’s unique needs and provide you with machines that are tailored to your specific requirements.

In conclusion, choosing the right vertical enameling machine manufacturer for your business is a crucial decision that can have a significant impact on your operations. By considering factors such as quality, reputation, cost, customer support, and experience, you can make an informed decision that will benefit your business in the long run. Take the time to research and evaluate different manufacturers before making a decision, and don’t hesitate to reach out to other businesses for recommendations and advice. With the right manufacturer by your side, you can ensure that your business has access to high-quality enameling machines that will help you achieve your production goals.