Table of Contents

Tips for Choosing the Right Aluminum Wire Drawing Machine for Your Business

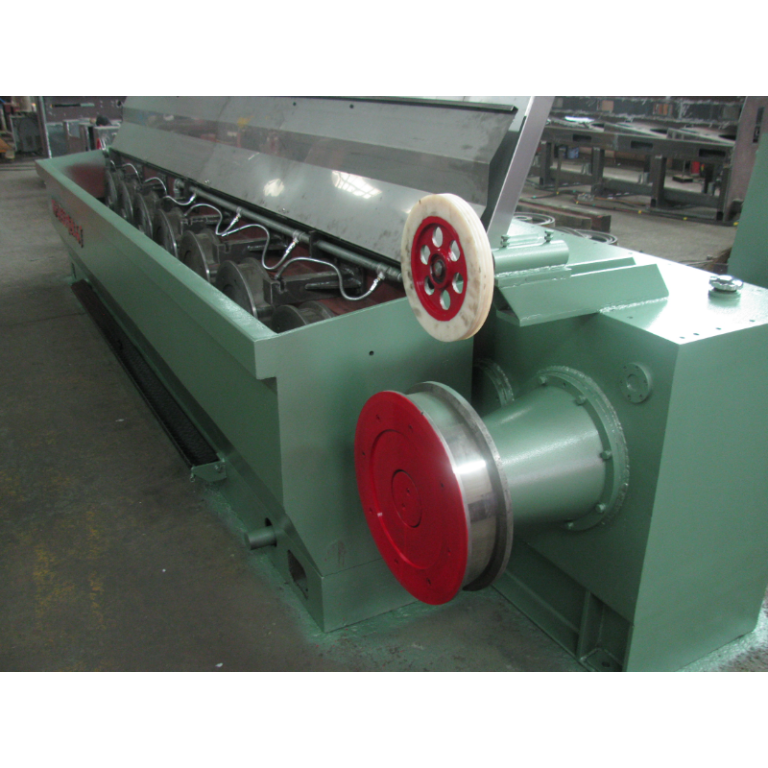

Aluminium wire drawing machines are essential equipment for businesses involved in the production of aluminium wires. These machines are used to reduce the diameter of aluminium rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. Choosing the right aluminium wire drawing machine for your business is crucial to ensure efficient production and high-quality output.

When selecting an aluminium wire drawing machine, there are several factors to consider. One of the most important factors is the size and type of wire you will be producing. Different machines are designed to handle different wire sizes and types, so it is essential to choose a machine that is suitable for your specific production needs. Additionally, consider the speed and efficiency of the machine, as well as its durability and reliability.

Another important factor to consider when choosing an Aluminum Alloy Wire Drawing Machine is the number of dies it has. The number of dies determines the number of times the wire will be drawn through the machine, which affects the final diameter and quality of the wire. Machines with more dies are capable of producing finer wires, while machines with fewer dies are better suited for thicker wires. Consider your production requirements and the desired wire diameter when selecting a machine with the appropriate number of dies.

It is also essential to consider the material and construction of the machine. Aluminum wire drawing machines are typically made of high-quality materials such as steel or aluminum to ensure durability and longevity. Look for machines with sturdy construction and high-quality components to ensure reliable performance and minimal downtime. Additionally, consider the maintenance requirements of the machine and choose one that is easy to clean and maintain to prolong its lifespan.

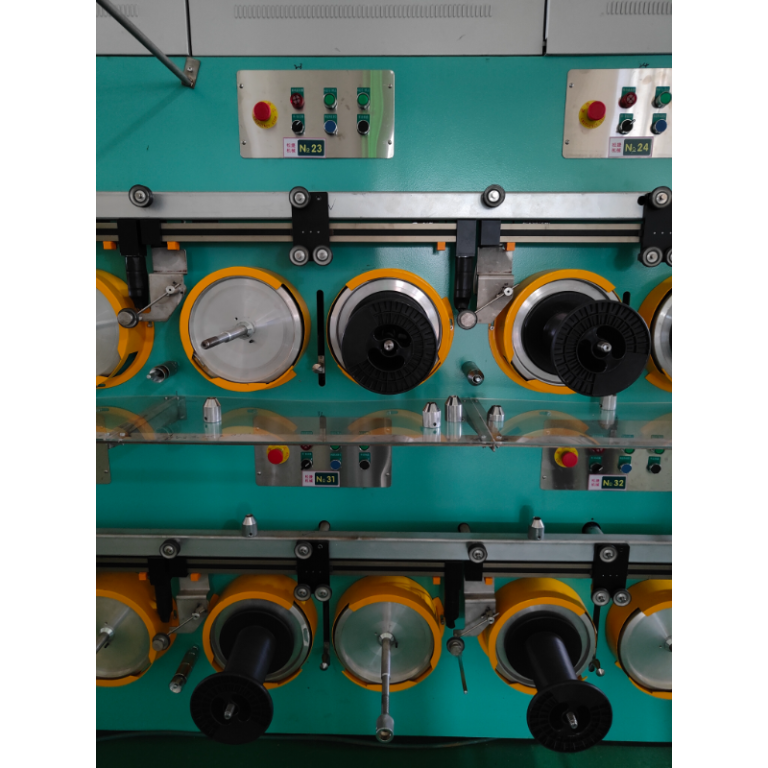

When selecting an aluminum wire drawing machine, it is also important to consider the level of automation and control features. Some machines come with advanced automation features such as digital controls, automatic wire threading, and speed adjustment, which can improve efficiency and productivity. Consider your production requirements and the level of automation you need when choosing a machine with the appropriate features.

In addition to these factors, it is also important to consider the reputation and reliability of the manufacturer. Choose a reputable manufacturer with a track record of producing high-quality aluminum wire drawing machines. Research customer reviews and testimonials to ensure that the manufacturer delivers reliable and durable machines that meet your production needs.

In conclusion, choosing the right aluminium wire drawing machine for your business is essential to ensure efficient production and high-quality output. Consider factors such as wire size, number of dies, material and construction, automation features, and manufacturer reputation when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific production requirements, you can ensure smooth and efficient wire drawing operations for your business.

Benefits of Using Aluminium Wire Drawing Machine in Manufacturing Processes

Aluminium wire drawing machines are essential tools in the manufacturing industry, particularly in the production of wires and cables. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its quality. The process involves applying pressure to the wire as it passes through the dies, resulting in a smoother and more uniform surface finish.

One of the key benefits of using an aluminium wire breakdown machine is the ability to produce wires of different diameters with high precision. This is crucial in industries where the quality and consistency of the wire are paramount, such as in the production of electrical cables, automotive components, and construction materials. By using a wire drawing machine, manufacturers can ensure that their products meet the required specifications and standards.

Another advantage of using an aluminium wire drawing machine is the ability to increase productivity and efficiency in the manufacturing process. These machines are capable of drawing wires at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This not only helps to meet the demand for products but also reduces production costs and improves overall profitability.

Furthermore, aluminium wire drawing machines are versatile tools that can be used to draw wires of various materials, including copper, steel, and aluminium. This flexibility allows manufacturers to adapt to changing market demands and produce a wide range of products to meet customer needs. By investing in a high-quality wire drawing machine, manufacturers can enhance their production capabilities and stay competitive in the industry.

In addition to improving productivity and versatility, aluminium wire drawing machines also offer benefits in terms of quality control and consistency. These machines are equipped with advanced technology and precision controls that ensure the wire is drawn to the desired specifications. This results in wires that are of high quality, with uniform diameter and surface finish, which is essential for the performance and reliability of the final products.

Moreover, using an aluminium wire drawing machine can help manufacturers reduce waste and improve sustainability in their operations. By drawing wires to the required diameter in a single pass, these machines minimize material loss and scrap, leading to cost savings and environmental benefits. This is particularly important in industries where raw materials are expensive or in high demand, as it helps to optimize resource utilization and reduce the carbon footprint of the manufacturing process.

Overall, the benefits of using an aluminium wire drawing machine in manufacturing processes are numerous and significant. From improving productivity and efficiency to enhancing quality control and sustainability, these machines play a crucial role in the production of high-quality wires and cables. By investing in a reliable and efficient wire drawing machine, manufacturers can streamline their operations, meet customer demands, and stay ahead of the competition in today’s fast-paced market.