Table of Contents

Maintenance Tips for Rod Breakdown Machine to Ensure Optimal Performance

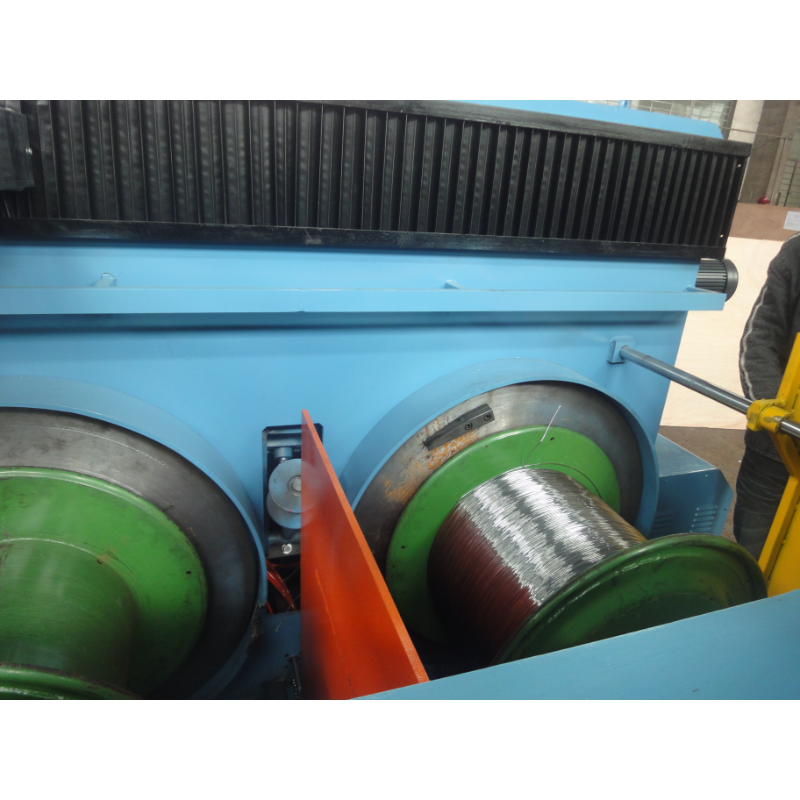

Rod Breakdown Machine for Aluminum Wire are essential equipment in the wire and cable manufacturing industry, particularly for processing aluminum wire. These machines are designed to reduce the diameter of aluminum rods to produce wire of various gauges. To ensure optimal performance and longevity of the rod breakdown machine, regular maintenance is crucial. In this article, we will discuss some maintenance tips for rod breakdown machines that can help you maximize their efficiency and productivity.

One of the most important maintenance tasks for a rod breakdown machine is regular cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential breakdowns. It is recommended to clean the machine thoroughly after each shift to prevent build-up and ensure smooth operation. Use a soft brush or compressed air to remove any particles from the machine’s surfaces, including the wire guides, rollers, and die holders.

In addition to cleaning, lubrication is another key aspect of rod breakdown machine maintenance. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and extending the machine’s lifespan. Make sure to use the recommended lubricants for each component, such as oil or grease, and apply them regularly according to the manufacturer’s guidelines. Pay special attention to high-wear areas, such as bearings and gears, to ensure they are adequately lubricated.

Regular inspection of the Intermediate Aluminum Wire Drawing Machine is also essential to identify any potential issues before they escalate. Check for signs of wear, damage, or misalignment in the machine’s components, such as rollers, dies, and drive belts. Replace any worn or damaged parts immediately to prevent further damage and ensure the machine’s continued operation. It is also important to inspect the electrical components, such as motors and control panels, for any signs of overheating or malfunction.

Calibration is another critical maintenance task for rod breakdown machines to ensure accurate wire diameter control. Periodically check and adjust the machine’s settings, such as speed, tension, and die clearance, to maintain consistent wire quality and gauge. Use a micrometer or other measuring tools to verify the wire diameter and make any necessary adjustments to the machine’s parameters. Proper calibration is essential for producing high-quality wire that meets industry standards.

Lastly, regular training and education for machine operators are essential for maintaining the rod breakdown machine’s optimal performance. Ensure that operators are familiar with the machine’s operation, maintenance procedures, and safety protocols to prevent accidents and downtime. Provide ongoing training and support to help operators troubleshoot common issues and perform routine maintenance tasks effectively. By investing in operator training, you can improve the overall efficiency and productivity of the rod breakdown machine.

In conclusion, proper maintenance is crucial for ensuring the optimal performance and longevity of a rod breakdown machine for aluminum wire. By following these maintenance tips, you can prevent breakdowns, reduce downtime, and maximize the machine’s efficiency. Regular cleaning, lubrication, inspection, calibration, and operator training are key aspects of rod breakdown machine maintenance that can help you achieve consistent and high-quality wire production. Remember to consult the manufacturer’s guidelines and recommendations for specific maintenance procedures and best practices.

Advantages of Using Rod Breakdown Machine for Aluminum Wire Production

Rod breakdown machines are essential equipment in the production of aluminum wire. These machines play a crucial role in the wire drawing process, where aluminum rods are reduced in diameter to produce wire of various sizes. The use of rod breakdown machines offers several advantages that make them indispensable in the aluminum wire production industry.

One of the primary advantages of using a aluminum wire drawing machine is the ability to achieve precise and consistent wire diameters. These machines are equipped with precision tools and controls that allow for accurate reduction of the rod diameter to the desired size. This ensures that the produced wire meets the required specifications and quality standards, making it suitable for a wide range of applications.

In addition to producing wire of consistent diameter, rod breakdown machines also offer high production efficiency. These machines are designed to operate at high speeds, allowing for rapid processing of aluminum rods into wire. This high production rate helps manufacturers meet the demand for aluminum wire in a timely manner, ensuring that they can fulfill orders and maintain a competitive edge in the market.

Another advantage of using a rod breakdown machine is the ability to reduce material waste. These machines are designed to minimize the amount of material that is lost during the wire drawing process, ensuring that manufacturers can maximize their production efficiency and reduce costs. By optimizing the use of aluminum rods and minimizing waste, rod breakdown machines help manufacturers improve their overall profitability.

Furthermore, rod breakdown machines are versatile and can be used to produce wire of various sizes and shapes. Manufacturers can easily adjust the settings of the machine to achieve the desired wire diameter, allowing for flexibility in production. This versatility makes rod breakdown machines suitable for a wide range of applications, from electrical wiring to automotive components.

In addition to their technical advantages, rod breakdown machines also offer ergonomic benefits for operators. These machines are designed with user-friendly controls and safety features that make them easy to operate and maintain. This helps reduce the risk of accidents and injuries in the workplace, ensuring a safe and efficient working environment for operators.

Overall, the advantages of using a rod breakdown machine for aluminum wire production are clear. From precise and consistent wire diameters to high production efficiency and reduced material waste, these machines offer numerous benefits that help manufacturers improve their production processes and achieve better results. With their versatility and ergonomic design, rod breakdown machines are essential equipment for any manufacturer in the aluminum wire industry.

How to Choose the Right Rod Breakdown Machine for Aluminum Wire Manufacturing

Rod breakdown machines are essential equipment in the manufacturing process of aluminum wire. These machines are designed to reduce the diameter of aluminum rods to the desired size, making them suitable for further processing into wire. Choosing the right rod breakdown machine is crucial for ensuring efficient production and high-quality output.

When selecting a rod breakdown machine for aluminum wire manufacturing, there are several factors to consider. One of the most important considerations is the type of material being processed. Aluminum wire is known for its soft and malleable properties, which require a specialized machine that can handle the material without causing damage.

It is essential to choose a rod breakdown machine that is specifically designed for processing aluminum wire. These machines are equipped with features such as adjustable speed controls, precision cutting tools, and cooling systems to ensure smooth and efficient operation. Additionally, the machine should have a sturdy construction and durable components to withstand the rigors of continuous use in a manufacturing environment.

Another important factor to consider when choosing a rod breakdown machine is the desired output size. Different machines are capable of reducing the diameter of aluminum rods to varying degrees, so it is essential to select a machine that can achieve the desired wire size for your specific application. Additionally, some machines are equipped with multiple dies that allow for the production of wire in different sizes, providing flexibility in manufacturing operations.

In addition to output size, it is also important to consider the production capacity of the rod breakdown machine. The machine should be able to process aluminum rods at a rate that meets the demands of your manufacturing operation. It is essential to choose a machine with a high production capacity to ensure efficient and timely production of aluminum wire.

Furthermore, when selecting a rod breakdown machine, it is crucial to consider the overall efficiency and reliability of the machine. Look for machines that are easy to operate and maintain, with minimal downtime for maintenance and repairs. Additionally, consider the energy efficiency of the machine, as this can have a significant impact on operating costs in the long run.

When evaluating different rod breakdown machines, it is also important to consider the reputation and track record of the manufacturer. Choose a machine from a reputable manufacturer with a history of producing high-quality equipment for the wire manufacturing industry. Look for manufacturers that offer comprehensive customer support and service to ensure that your machine operates at peak performance.

In conclusion, choosing the right rod breakdown machine for aluminum wire manufacturing is essential for ensuring efficient production and high-quality output. Consider factors such as material compatibility, output size, production capacity, efficiency, and reliability when selecting a machine. By carefully evaluating these factors and choosing a machine from a reputable manufacturer, you can ensure that your manufacturing operation runs smoothly and effectively.