Table of Contents

Advantages of Using Slip Type Wire Drawing Machine For Aluminum Wire

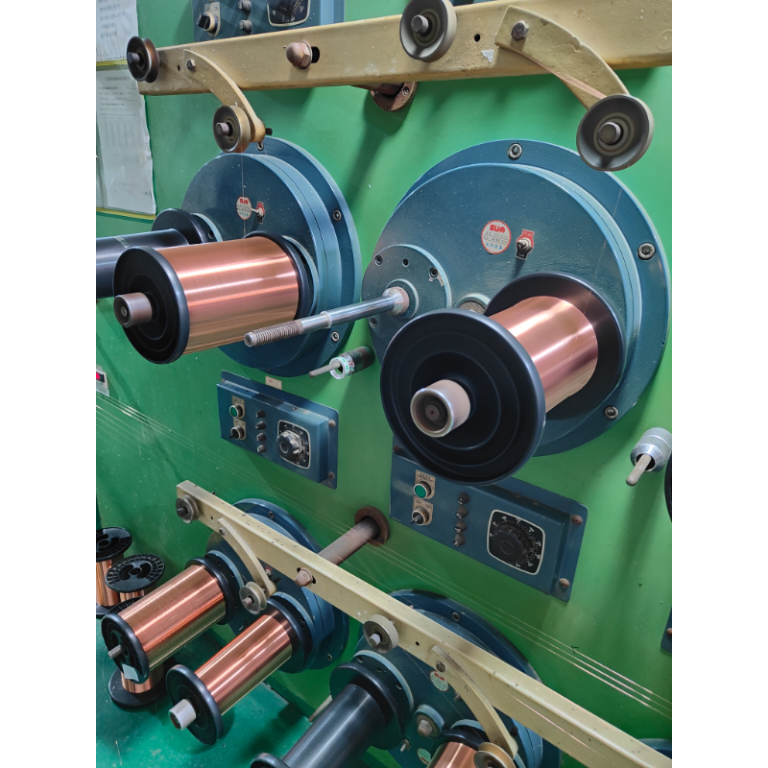

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including aluminum wire. One type of wire drawing machine that is commonly used for drawing aluminum wire is the slip type wire drawing machine. This machine offers several advantages over other types of wire drawing machines, making it a popular choice for manufacturers.

One of the main advantages of using a slip type wire drawing machine for Aluminum Alloy Wire Drawing Machine is its ability to produce high-quality wire with a smooth surface finish. The slip type machine uses a slip ring to control the speed of the wire as it passes through the dies, allowing for precise control over the drawing process. This results in a wire that is free from defects and has a consistent diameter throughout its length. The smooth surface finish of the wire produced by a slip type machine makes it ideal for use in applications where appearance is important, such as in the production of electrical wiring or jewelry.

In addition to producing high-quality wire, slip type wire drawing machines are also known for their efficiency. These machines are able to draw wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to increase productivity and reduce production costs, making slip type wire drawing machines a cost-effective option for manufacturers.

Another advantage of using a slip type wire drawing machine for aluminum wire is its versatility. These machines are capable of drawing wire in a wide range of diameters, making them suitable for use in a variety of applications. Whether you need to produce thin wire for electrical wiring or thicker wire for industrial applications, a slip type machine can be easily adjusted to meet your specific requirements.

Furthermore, slip type wire drawing machines are also known for their durability and reliability. These machines are built to withstand the rigors of continuous use in a manufacturing environment, making them a long-lasting investment for manufacturers. With proper maintenance and care, a slip type machine can provide years of reliable service, helping to ensure consistent production of high-quality wire.

Overall, slip type wire drawing machines offer a number of advantages for manufacturers looking to produce high-quality aluminum wire. From their ability to produce smooth surface finishes to their efficiency and versatility, these machines are a valuable tool for any manufacturer working with aluminum wire. With their durability and reliability, slip type wire drawing machines are a smart investment for manufacturers looking to improve their wire drawing processes and increase productivity.

Tips for Maintaining and Troubleshooting Slip Type Wire Drawing Machine for Aluminum Wire

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of aluminum wire, which is widely used in various industries. One type of wire drawing machine that is commonly used for Aluminum Wire Drawing Machine is the slip type wire drawing machine. This machine is designed to draw aluminum wire through a series of dies by using a slip mechanism to control the speed and tension of the wire.

Maintaining a slip type wire drawing machine is essential to ensure its optimal performance and longevity. Regular maintenance can help prevent breakdowns and costly repairs. One important aspect of maintaining a slip type wire drawing machine is to regularly lubricate the moving parts. This will help reduce friction and wear on the machine, prolonging its lifespan. It is also important to regularly inspect the machine for any signs of wear or damage, such as worn out dies or broken parts. These should be replaced immediately to prevent further damage to the machine.

Another important aspect of maintaining a slip type wire drawing machine is to regularly clean the machine to remove any dirt or debris that may have accumulated. This will help prevent clogs and blockages that can affect the performance of the machine. It is also important to check the alignment of the machine regularly to ensure that it is operating correctly. Misalignment can cause uneven drawing of the wire, leading to poor quality output.

In addition to regular maintenance, it is also important to troubleshoot any issues that may arise with the slip type wire drawing machine. One common issue that may occur is slipping of the wire in the machine. This can be caused by a variety of factors, such as worn out dies, improper tension settings, or misalignment of the machine. To troubleshoot this issue, it is important to first check the tension settings and adjust them accordingly. If the issue persists, it may be necessary to replace the dies or realign the machine.

Another common issue that may occur with a slip type wire drawing machine is overheating. This can be caused by a variety of factors, such as excessive friction or a malfunctioning cooling system. To troubleshoot this issue, it is important to first check the cooling system and ensure that it is functioning properly. It may also be necessary to reduce the speed of the machine to reduce friction and prevent overheating.

Overall, maintaining and troubleshooting a slip type wire drawing machine for aluminum wire is essential to ensure its optimal performance and longevity. Regular maintenance, such as lubricating moving parts, inspecting for wear and damage, and cleaning the machine, can help prevent breakdowns and costly repairs. Troubleshooting common issues, such as slipping of the wire or overheating, can help ensure that the machine is operating correctly and producing high-quality output. By following these tips, you can ensure that your slip type wire drawing machine for aluminum wire remains in top condition for years to come.