Merits of Using a Copper Wire Drawing Machine With Annealer

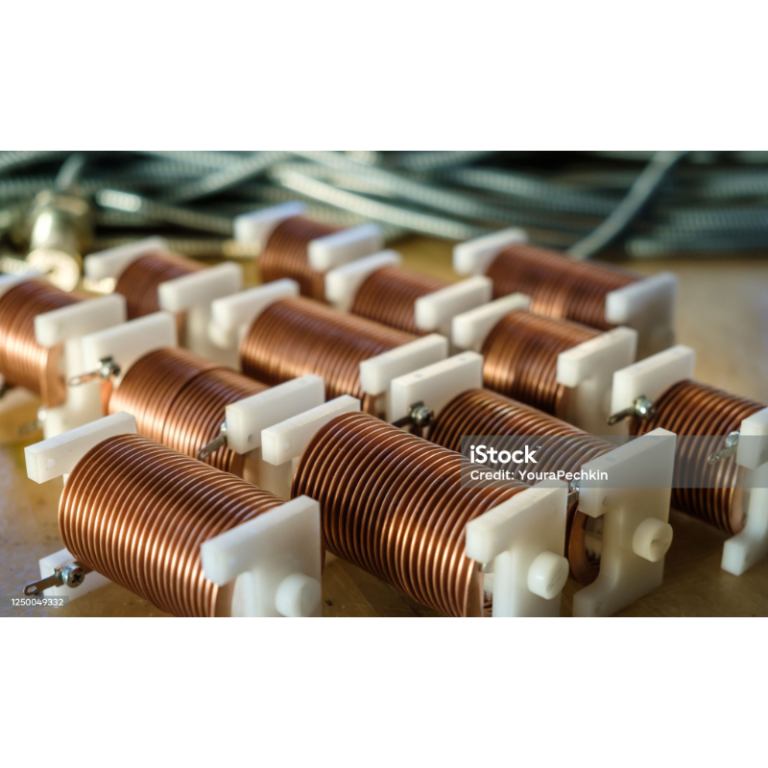

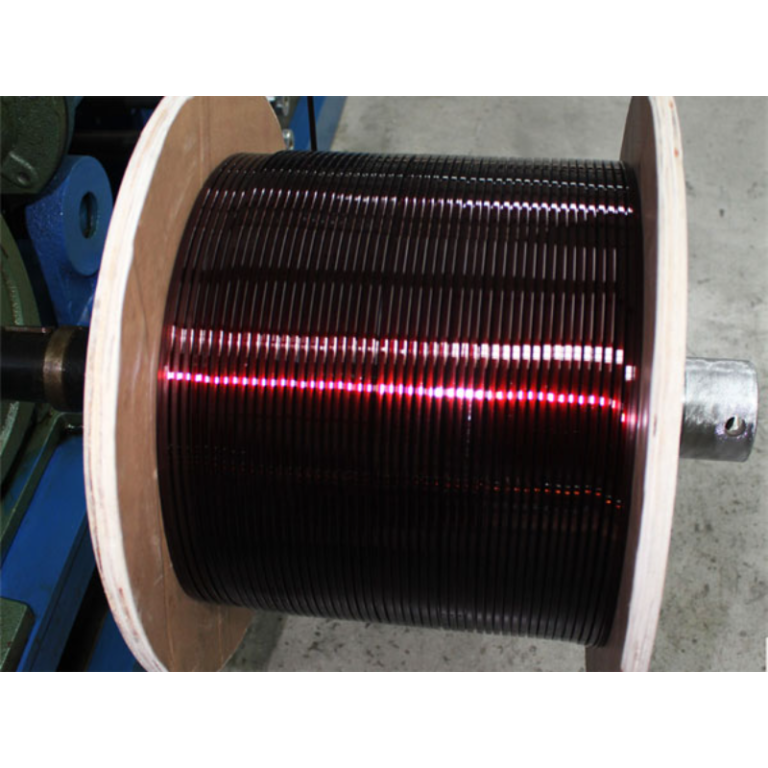

Copper wire drawing machines with annealers are essential tools in the wire manufacturing industry. These machines are designed to draw copper wire through a series of dies to reduce its diameter and improve its quality. The annealer component of the machine helps to soften the copper wire, making it more malleable and easier to work with. There are several benefits to using a copper wire drawing machine with an annealer, including increased productivity, improved wire quality, and reduced production costs.

One of the primary benefits of using a copper wire drawing machine with an annealer is increased productivity. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to meet the demands of customers and ensure that production deadlines are met. Additionally, the annealer component of the machine helps to reduce the risk of wire breakage during the drawing process, further increasing productivity by minimizing downtime.

Another benefit of using a Copper Wire Drawing Machine for Rod Breakdown Machine is improved wire quality. The annealing process helps to remove any internal stresses in the copper wire, resulting in a smoother and more uniform surface finish. This can help to reduce the risk of defects in the wire, such as cracks or imperfections, and ensure that the wire meets the required specifications for its intended use. Additionally, the drawing process helps to improve the mechanical properties of the wire, making it stronger and more durable.

In addition to increased productivity and improved wire quality, using a copper wire drawing machine with an annealer can also help to reduce production costs. By drawing wire at high speeds, manufacturers can produce more wire in less time, reducing labor costs and increasing efficiency. The annealing process can also help to reduce the amount of scrap material produced during the drawing process, further lowering production costs. Additionally, the improved quality of the wire produced by these machines can help to reduce the risk of product defects and returns, saving manufacturers money in the long run.

Overall, using a copper wire drawing machine with an annealer offers a range of benefits for manufacturers in the wire industry. These machines can help to increase productivity, improve wire quality, and reduce production costs, making them essential tools for any wire manufacturing operation. By investing in a high-quality copper wire drawing machine with an annealer, manufacturers can ensure that they are able to meet the demands of their customers and produce high-quality wire products that meet the required specifications.