Table of Contents

Maintenance Tips for Copper Wire Drawing Making Machine

Copper wire drawing making machines are essential equipment in the manufacturing industry, used to produce high-quality copper wires of various sizes and gauges. These machines are complex pieces of machinery that require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some maintenance tips for copper wire drawing making machines to help you keep your equipment in top condition.

One of the most important maintenance tasks for copper wire drawing making machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help reduce friction and wear, prolonging the machine’s lifespan.

Another crucial maintenance tip for High Efficiency Advanced Copper Wire Drawing Machine is inspecting the machine for any signs of wear or damage. Check the machine’s components, such as the drawing dies, rollers, and bearings, for any signs of wear or corrosion. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure smooth operation.

Regularly monitoring the machine’s performance is also essential for proper maintenance. Keep an eye on the machine’s speed, tension, and temperature to ensure that it is operating within the recommended parameters. Any deviations from the normal operating conditions could indicate a problem that needs to be addressed promptly.

In addition to regular cleaning and inspection, it is crucial to follow the manufacturer’s recommended maintenance schedule for your copper wire drawing machine. This schedule will outline specific maintenance tasks that need to be performed at regular intervals, such as replacing worn parts, adjusting tension settings, and cleaning the machine’s components. By following the manufacturer’s guidelines, you can ensure that your machine remains in optimal condition and operates efficiently.

Proper storage of the copper wire drawing making machine is also essential for maintaining its performance. Store the machine in a clean, dry, and well-ventilated area to prevent dust and moisture from accumulating on the machine’s components. Cover the machine when not in use to protect it from dust and debris.

Lastly, regular training for machine operators on proper maintenance procedures is crucial for ensuring the longevity and efficiency of your copper wire drawing making machine. Make sure that your operators are familiar with the machine’s maintenance requirements and know how to perform basic maintenance tasks. This will help prevent costly repairs and downtime due to improper maintenance practices.

In conclusion, proper maintenance of copper wire drawing making machines is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machine in top condition and avoid costly repairs and downtime. Regular cleaning, inspection, monitoring, and following the manufacturer’s recommended maintenance schedule are key to keeping your copper wire drawing making machine running smoothly. Remember to store the machine properly and provide training for operators on proper maintenance procedures to maximize the lifespan of your equipment.

Benefits of Using Copper Wire Drawing Making Machines

Copper wire drawing making machines are essential tools in the manufacturing industry for producing high-quality copper wires. These machines are designed to draw copper rods through a series of dies to reduce their diameter and improve their quality. There are several benefits to using copper wire drawing making machines, including increased efficiency, cost savings, and improved product quality.

One of the primary benefits of using copper wire drawing making machines is increased efficiency. These machines are capable of drawing copper wires at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help companies meet tight production deadlines and fulfill customer orders quickly. Additionally, the automated nature of these machines reduces the need for manual labor, further increasing efficiency and reducing production costs.

Another benefit of using Copper Fine Wire Drawing Machine With Annealer is cost savings. By automating the wire drawing process, manufacturers can reduce labor costs and minimize waste. These machines are designed to draw copper wires with precision, resulting in less material being wasted during the manufacturing process. Additionally, the high-speed operation of these machines can help companies save on energy costs by reducing the amount of time required to produce each wire.

In addition to increased efficiency and cost savings, using copper wire drawing making machines can also lead to improved product quality. These machines are equipped with advanced technology that allows for precise control over the wire drawing process. This results in wires that are uniform in diameter and have a smooth surface finish, making them ideal for use in a variety of applications. The consistent quality of wires produced by these machines can help manufacturers build a reputation for reliability and excellence in their industry.

Furthermore, copper wire drawing making machines are versatile tools that can be used to produce wires of various diameters and lengths. This flexibility allows manufacturers to meet the specific needs of their customers and produce wires for a wide range of applications. Whether it’s for electrical wiring, telecommunications, or industrial machinery, these machines can be customized to produce wires that meet the exact specifications required by the customer.

In conclusion, copper wire drawing making machines offer numerous benefits to manufacturers in the production of high-quality copper wires. From increased efficiency and cost savings to improved product quality and versatility, these machines are essential tools for companies looking to stay competitive in the manufacturing industry. By investing in copper wire drawing making machines, manufacturers can streamline their production processes, reduce costs, and deliver superior products to their customers.

How Copper Wire Drawing Making Machines Work

Copper wire drawing making machines are essential tools in the manufacturing process of copper wires. These machines are used to reduce the diameter of copper rods or wires by pulling them through a series of dies, resulting in a thinner and longer wire. The process of wire drawing involves several steps that are carried out by the machine to achieve the desired outcome.

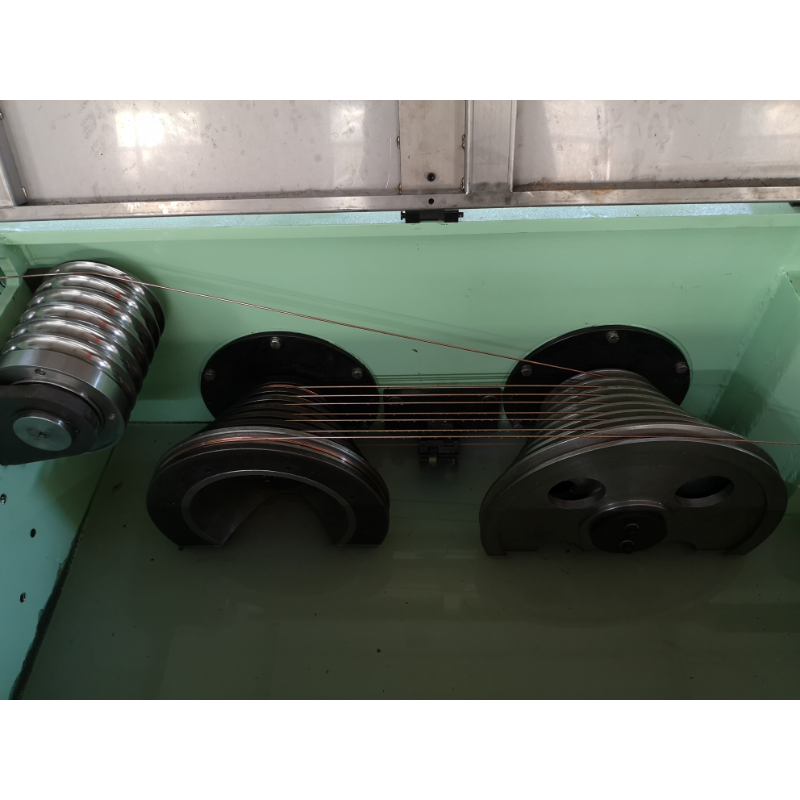

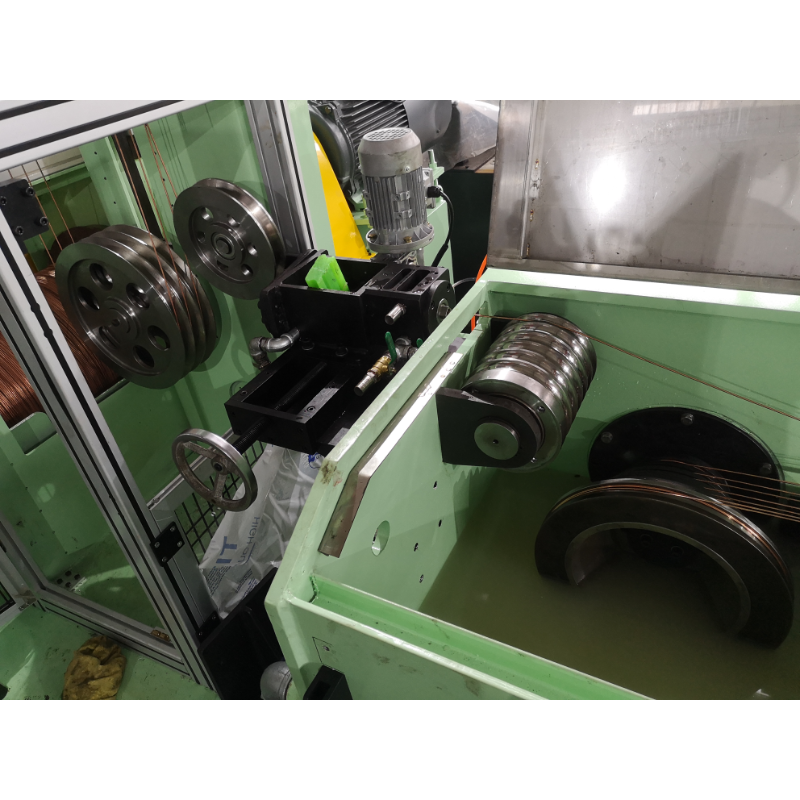

The first step in the wire drawing process is to feed the Copper Rod Casting and Making Machine. The machine consists of a series of rollers that guide the wire through the drawing dies. These dies are made of hardened steel and have a hole with a diameter slightly smaller than the wire being drawn. As the wire passes through the dies, it is compressed and elongated, reducing its diameter.

The drawing process is achieved by pulling the wire through the dies using a capstan or a drum. The capstan is a rotating device that grips the wire and pulls it through the dies at a controlled speed. The drum, on the other hand, is a rotating cylinder that winds the wire around it as it is pulled through the dies. Both methods are effective in drawing the wire, but the choice of method depends on the specific requirements of the wire being produced.

As the wire is drawn through the dies, it undergoes a series of reductions in diameter. Each die in the machine is slightly smaller than the previous one, causing the wire to become thinner with each pass. The number of dies used in the machine depends on the desired final diameter of the wire. The wire may pass through several dies before reaching the desired diameter, with each pass increasing the length of the wire.

The drawing process also work-hardens the wire, making it stronger and more durable. This is achieved by the compression and elongation of the wire as it passes through the dies. The wire is also straightened during the drawing process, resulting in a smooth and uniform surface finish.

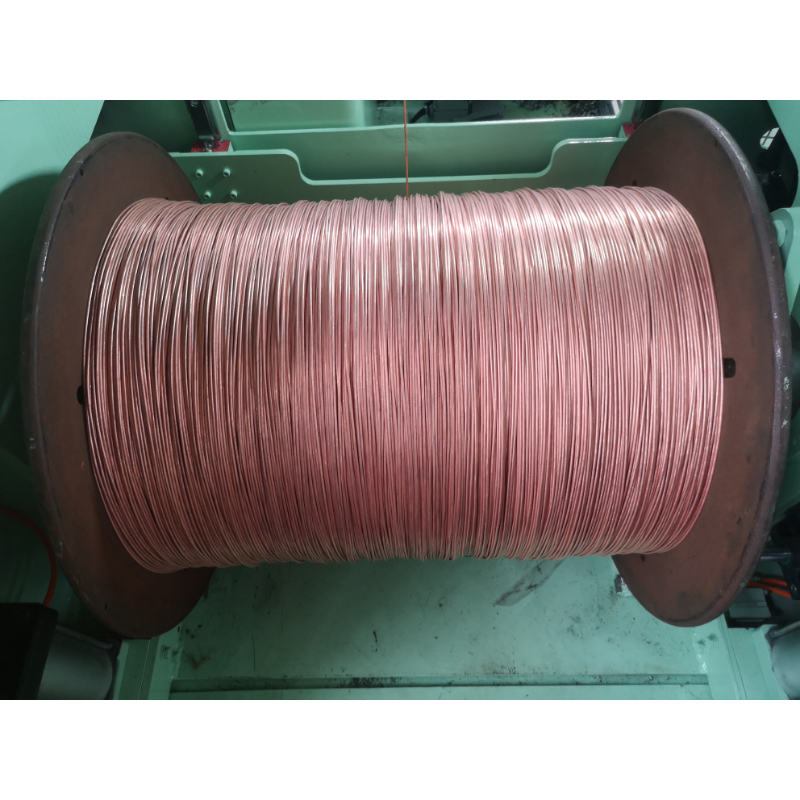

After the wire has been drawn to the desired diameter, it is wound onto a spool or a drum for further processing. The spooling process involves winding the wire onto a spool in a neat and organized manner. This makes it easier to handle and transport the wire for further processing or distribution.

Copper wire drawing making machines are versatile tools that can be used to produce a wide range of wire sizes and types. They are commonly used in industries such as electrical, telecommunications, and construction. The machines are available in various sizes and configurations to suit different production requirements.

In conclusion, copper wire drawing making machines play a crucial role in the manufacturing process of copper wires. The machines work by pulling the wire through a series of dies to reduce its diameter and increase its length. The drawing process results in a stronger and more durable wire that is suitable for a variety of applications. With their versatility and efficiency, copper wire drawing making machines are indispensable tools in the production of high-quality copper wires.