Table of Contents

Tips for Maintaining and Troubleshooting Single Block Wire Drawing Machine For Copper Wire Manufacturing

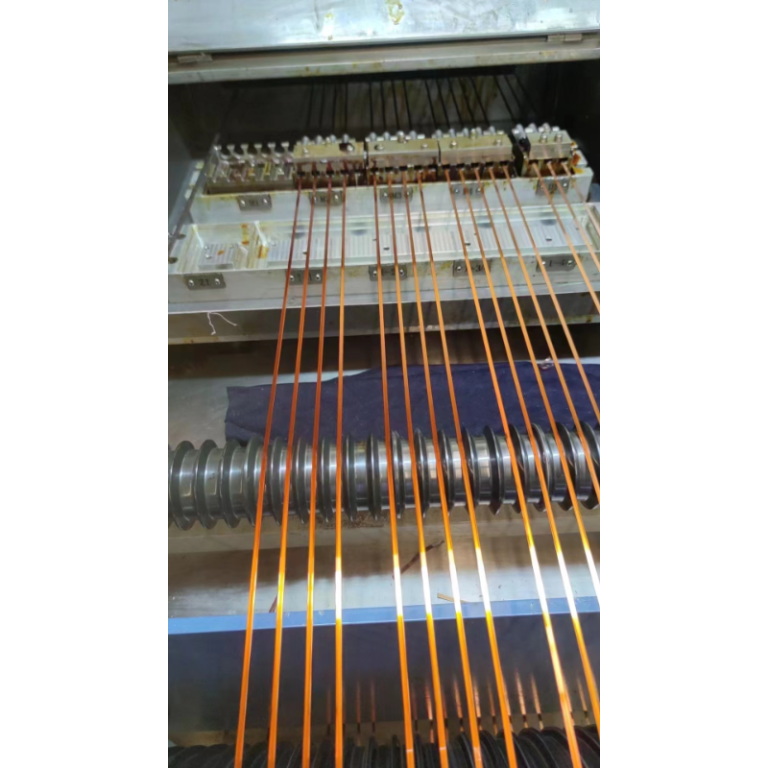

Single block wire drawing machines are essential equipment in the copper wire manufacturing industry. These machines are used to reduce the diameter of copper wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. Proper maintenance and troubleshooting of single block wire drawing machines are crucial to ensure optimal performance and longevity of the equipment.

Regular maintenance is key to keeping single block wire drawing machines in good working condition. One of the most important maintenance tasks is to regularly lubricate the machine to reduce friction and wear on the moving parts. Using the correct type and amount of lubricant is essential to prevent damage to the machine and ensure smooth operation.

In addition to lubrication, it is important to regularly inspect the machine for any signs of wear or damage. Check for loose or worn parts, such as belts, pulleys, and bearings, and replace them as needed. Keeping the machine clean and free of debris is also important to prevent clogs and other issues that can affect performance.

Another important aspect of maintaining single block wire drawing machines is to regularly check and adjust the tension of the wire. Proper tension is crucial for achieving the desired wire diameter and quality. Adjust the tension according to the specifications provided by the manufacturer to ensure optimal performance.

When troubleshooting Copper Fine Wire Drawing Machine With Annealer, it is important to start by identifying the problem and its possible causes. Common issues that may arise include uneven wire diameter, wire breakage, and machine jamming. By systematically checking each component of the machine, you can pinpoint the source of the problem and take appropriate action to resolve it.

If the wire diameter is uneven, check the dies for wear or damage and replace them if necessary. Adjusting the tension and speed of the machine may also help to achieve a more uniform wire diameter. If the wire is breaking frequently, check for any sharp edges or burrs on the dies that may be causing damage to the wire. Adjusting the tension and speed of the machine can also help to prevent wire breakage.

Machine jamming can be caused by a variety of factors, such as debris or foreign objects getting stuck in the machine or improper alignment of the components. Clearing any obstructions and ensuring proper alignment of the machine can help to prevent jamming issues. Regularly cleaning and inspecting the machine can also help to prevent jamming and other issues.

In conclusion, proper maintenance and troubleshooting of single block wire drawing machines are essential for ensuring optimal performance and longevity of the equipment. By following these tips and guidelines, you can keep your machine in good working condition and minimize downtime due to maintenance issues. Regular inspection, lubrication, and adjustment of the machine are key to preventing problems and ensuring smooth operation. If you encounter any issues with your machine, systematically troubleshoot the problem to identify the cause and take appropriate action to resolve it. With proper care and maintenance, your single block wire drawing machine can continue to produce high-quality copper wire for years to come.

Benefits of Using Single Block Wire Drawing Machine for Copper Wire Production

Copper wire is a versatile material that is used in a wide range of industries, from electronics to construction. In order to produce high-quality copper wire, manufacturers rely on wire drawing machines to reduce the diameter of the wire and improve its mechanical properties. One type of wire drawing machine that is commonly used for copper wire production is the single block wire drawing machine.

The single block wire drawing machine is a simple and efficient machine that is designed to draw copper wire through a single die block. This type of machine is ideal for small to medium-scale copper wire production, as it offers a number of benefits that make it a cost-effective and reliable option for manufacturers.

One of the key benefits of using a single block wire drawing machine for Copper Multiwire Drawing Machine is its compact size. Unlike multi-block wire drawing machines, which can be large and complex, single block machines are typically smaller and more streamlined. This makes them easier to install and operate, and also reduces the amount of floor space required for production. For manufacturers with limited space or budget constraints, a single block wire drawing machine can be a practical and efficient solution.

In addition to their compact size, single block wire drawing machines are also known for their simplicity and ease of use. These machines are designed to be user-friendly, with intuitive controls and minimal maintenance requirements. This makes them ideal for manufacturers who are new to wire drawing or who have limited experience with this type of equipment. With a single block wire drawing machine, operators can quickly and easily set up the machine, adjust the drawing parameters, and monitor the production process with minimal training or supervision.

Another benefit of using a single block wire drawing machine for copper wire production is its versatility. These machines are capable of drawing copper wire in a wide range of diameters, from fine wires used in electronics to thicker wires used in construction. This flexibility allows manufacturers to produce a variety of wire sizes and types with a single machine, reducing the need for multiple machines and increasing production efficiency.

In addition to their compact size, simplicity, and versatility, single block wire drawing machines are also known for their high efficiency and productivity. These machines are designed to draw wire at high speeds, with minimal downtime and waste. This allows manufacturers to produce large quantities of high-quality copper wire in a short amount of time, increasing overall production output and reducing costs.

Overall, the single block wire drawing machine is a practical and efficient option for manufacturers looking to produce high-quality copper wire. With its compact size, simplicity, versatility, and high efficiency, this type of machine offers a number of benefits that make it a cost-effective and reliable choice for small to medium-scale copper wire production. By investing in a single block wire drawing machine, manufacturers can improve their production processes, increase output, and meet the growing demand for high-quality copper wire in a variety of industries.