Advantages Of Using Wet Type Drawing Machines For Copper Wire

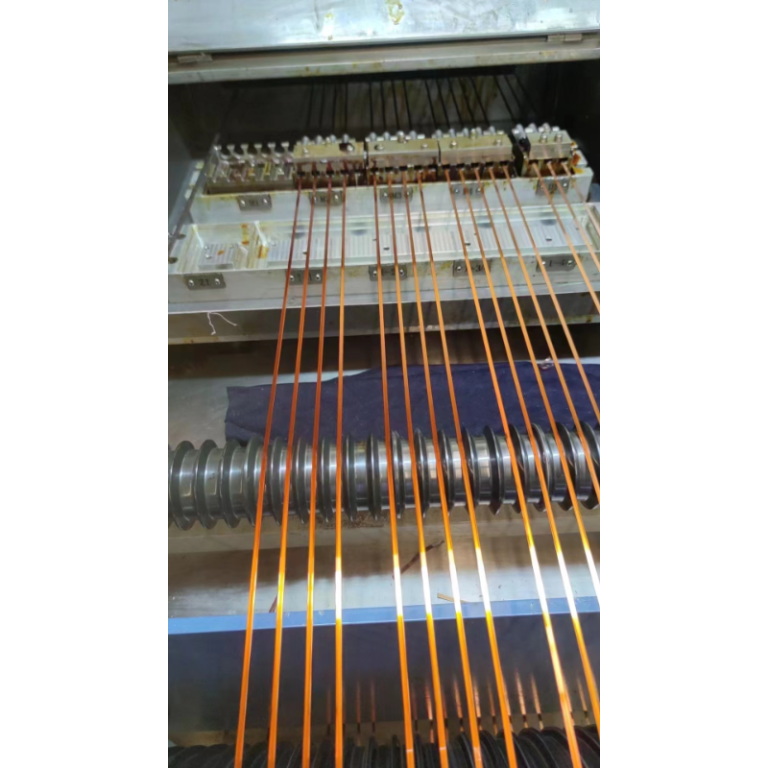

Wet type drawing machines are a crucial tool in the production of copper wire type drawing machine. These machines are designed to efficiently draw copper wire through a series of dies to reduce its diameter and improve its quality. While there are various types of drawing machines available, wet type drawing machines offer several advantages that make them a popular choice for many manufacturers.

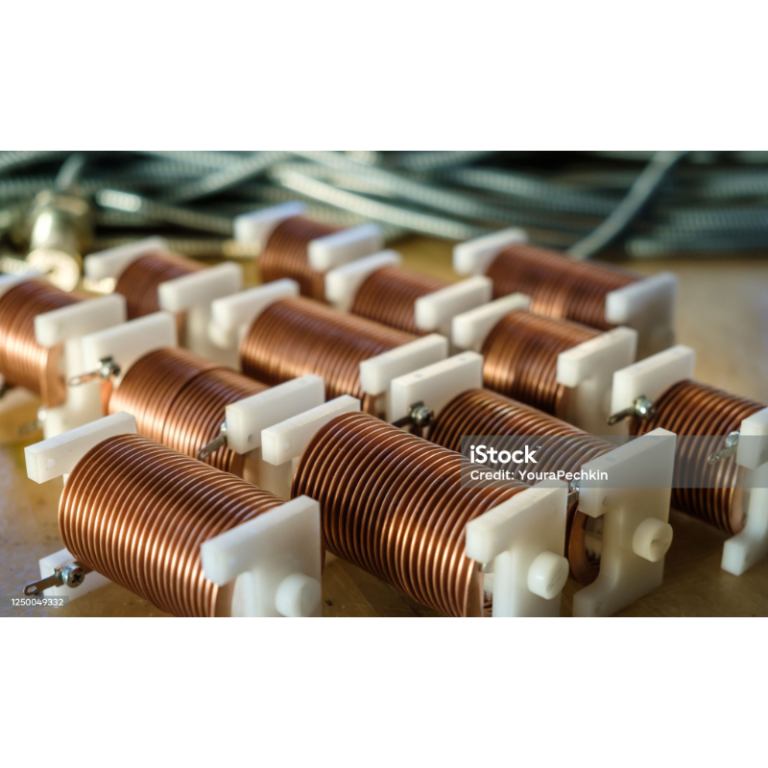

One of the key advantages of using Copper Fine Wire Drawing Machine With Annealer is their ability to reduce friction during the drawing process. The use of a lubricant, typically water-based, helps to cool the wire and dies, reducing heat generation and friction. This results in a smoother drawing process and a higher quality finished product. Additionally, the lubricant helps to remove any impurities or contaminants from the surface of the wire, resulting in a cleaner and more uniform finish.

Another advantage of wet type drawing machines is their ability to improve the surface finish of the copper wire. The lubricant used in these machines helps to reduce surface defects such as scratches and marks, resulting in a smoother and more polished finish. This is particularly important for applications where the appearance of the wire is critical, such as in the production of electrical cables or fine wire products.

In addition to improving the surface finish of the wire, Copper Wire Drawing Machine also help to increase the productivity of the drawing process. The use of a lubricant reduces the amount of force required to draw the wire through the dies, allowing for faster drawing speeds and higher production rates. This can result in significant cost savings for manufacturers, as they are able to produce more wire in less time.

Furthermore, wet type drawing machines are known for their ability to extend the life of the dies used in the drawing process. The lubricant helps to reduce wear and tear on the dies, resulting in longer die life and reduced maintenance costs. This can be particularly beneficial for manufacturers who are looking to maximize the lifespan of their equipment and minimize downtime for maintenance and repairs.

Overall, wet type drawing machines offer a range of advantages for manufacturers producing copper wire. From reducing friction and improving surface finish to increasing productivity and extending die life, these machines are a valuable tool in the production process. By investing in wet type drawing machines, manufacturers can improve the quality of their copper wire products and achieve greater efficiency in their operations.