Table of Contents

Benefits of Using a Vertical Enameling Machine

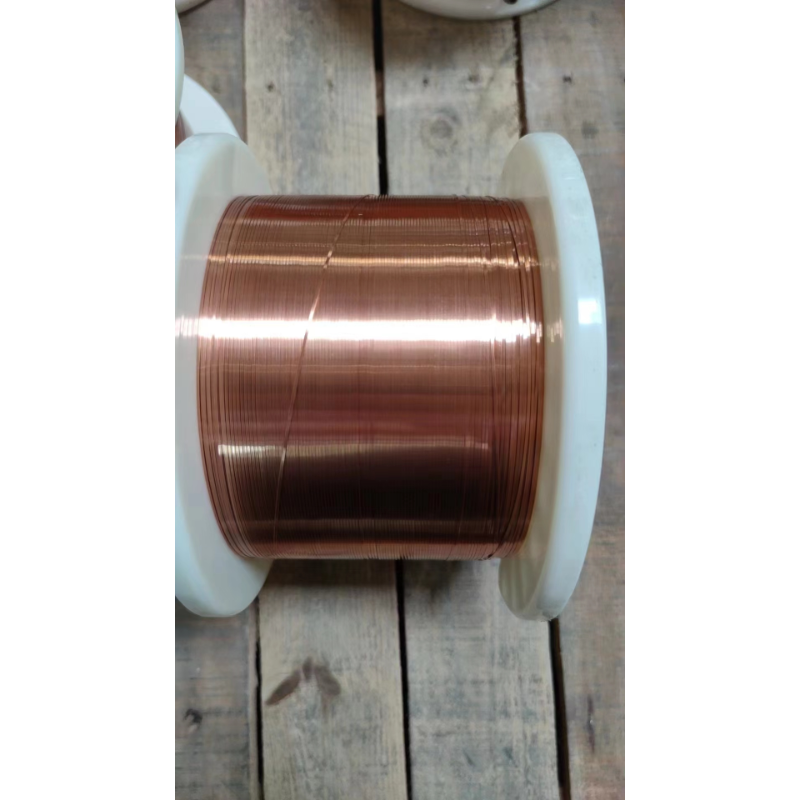

Enameling copper wire is a crucial process in the manufacturing of electrical components such as motors, transformers, and generators. The enamel coating on copper wire serves as insulation, protecting the wire from damage and ensuring the efficient transmission of electricity. Traditionally, enameling copper wire was a labor-intensive process that required skilled workers to manually apply the enamel coating. However, with advancements in technology, vertical enameling machines have revolutionized the enameling process, offering numerous benefits to manufacturers.

One of the primary benefits of using a Vertical Enameling Machine for Copper Wire is increased efficiency. These machines are designed to automate the enameling process, significantly reducing the time and labor required to coat copper wire. By eliminating the need for manual labor, manufacturers can increase their production output and meet tight deadlines more effectively. Additionally, vertical enameling machines are equipped with advanced features such as automatic tension control and temperature monitoring, ensuring consistent and high-quality enamel coatings on every wire.

Another advantage of using a vertical enameling machine is improved quality control. These machines are equipped with sensors and monitoring systems that detect any defects or inconsistencies in the enamel coating. This allows manufacturers to identify and rectify any issues in real-time, ensuring that only high-quality copper wire is produced. By maintaining strict quality control standards, manufacturers can reduce the risk of product defects and customer complaints, ultimately enhancing their reputation in the industry.

In addition to efficiency and quality control, vertical enameling machines offer cost savings to manufacturers. By automating the enameling process, these machines reduce the need for manual labor, ultimately lowering labor costs. Furthermore, the consistent and precise application of enamel coatings by vertical enameling machines minimizes material wastage, resulting in cost savings for manufacturers. Overall, investing in a vertical enameling machine can lead to long-term cost reductions and improved profitability for manufacturers.

Furthermore, vertical enameling machines are versatile and can accommodate a wide range of wire sizes and enamel types. Whether manufacturers are working with thin or thick copper wire, or require different types of enamel coatings, these machines can be easily adjusted to meet specific production requirements. This flexibility allows manufacturers to diversify their product offerings and cater to a broader range of customer needs, ultimately expanding their market reach and increasing their competitiveness in the industry.

In conclusion, the benefits of using a vertical enameling machine for copper wire are numerous and significant. From increased efficiency and quality control to cost savings and versatility, these machines offer a range of advantages to manufacturers. By investing in a vertical enameling machine, manufacturers can streamline their production processes, improve product quality, and enhance their overall competitiveness in the market. As technology continues to advance, vertical enameling machines will undoubtedly play a crucial role in the future of copper wire manufacturing.

Tips for Maintaining and Troubleshooting a Vertical Enameling Machine for Copper Wire

Vertical enameling machines are essential tools in the production of copper wire, as they provide a protective coating that enhances the wire’s durability and conductivity. However, like any piece of machinery, these machines require regular maintenance and troubleshooting to ensure optimal performance. In this article, we will discuss some tips for maintaining and troubleshooting a vertical enameling machine for copper wire.

One of the most important aspects of maintaining a vertical enameling machine is keeping it clean. Dust, dirt, and debris can build up on the machine’s components over time, leading to decreased efficiency and potential malfunctions. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent these issues and prolong the machine’s lifespan.

In addition to cleaning, it is crucial to lubricate the machine’s moving parts regularly. Lubrication helps reduce friction and wear on the machine’s components, ensuring smooth operation and preventing breakdowns. Be sure to use the appropriate type of lubricant for each part of the machine, as using the wrong type can cause damage.

Another important maintenance tip is to inspect the machine’s electrical components regularly. Loose connections, frayed wires, or damaged components can lead to electrical malfunctions that can be dangerous and costly to repair. If you notice any issues with the machine’s electrical system, it is best to shut off the power and contact a qualified technician for repairs.

When it comes to troubleshooting a vertical enameling machine, one of the most common issues is uneven coating on the wire. This can be caused by a variety of factors, such as improper tension settings, worn-out dies, or a dirty coating chamber. To address this issue, start by checking the tension settings and adjusting them as needed. If the problem persists, inspect the dies for wear and replace them if necessary. Finally, clean the coating chamber thoroughly to ensure an even application of enamel.

Another common issue with vertical enameling machines is overheating. Overheating can be caused by a variety of factors, such as a clogged cooling system, a malfunctioning thermostat, or excessive friction in the machine’s components. To address this issue, start by checking the cooling system and cleaning any clogs that may be restricting airflow. If the problem persists, check the thermostat and replace it if necessary. Finally, inspect the machine’s moving parts for signs of excessive wear and lubricate them as needed.

In conclusion, maintaining and troubleshooting a vertical enameling machine for copper wire is essential for ensuring optimal performance and prolonging the machine’s lifespan. By following the tips outlined in this article, you can keep your machine running smoothly and prevent costly breakdowns. Remember to clean the machine regularly, lubricate its moving parts, inspect its electrical components, and address any issues promptly to keep your vertical enameling machine in top condition.